Care and maintenance, Carburetor adjustments, Important – Bolens 520 User Manual

Page 10: Impeller clutch adjustment, Paddle replacement, Note

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CARE AND MAINTENANCE

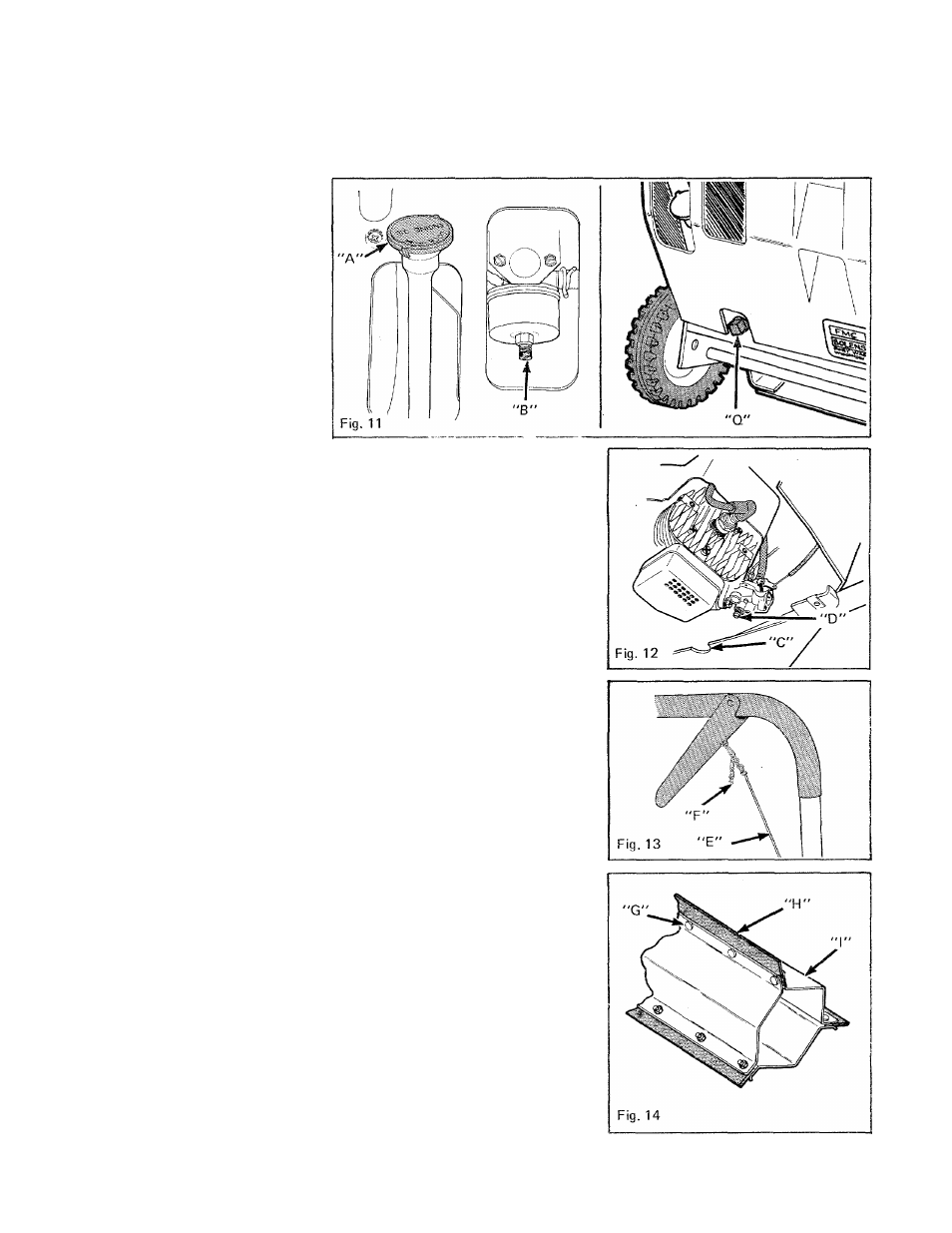

operating position (wheels and

scraper blade on the ground). Clean

dirt and/or snow from around open

ing (A), Figure 11. Keep oil level to

"FULL" mark on dipstick. Refer to

Engine Manual for proper proce

dure to drain and refill engine

crankcase. The drain plug (Q), Fig

ure 11 is located on backside of unit

in the bottom left-hand corner.

Refer to Engine Manual and/or

BEFORE OPERATION instructions

for proper type oil and quantity.

CARBURETOR ADJUSTMENTS

DO NOT MAKE UNNECESSARY

ADJUSTMENTS. FACTORY SET

TINGS ARE SATISFACTORY FOR

MOST APPLICATIONS AND CON

DITIONS. HOWEVER IF ADJUST

MENTS ARE NEEDED, PROCEED

AS FOLLOWS.

4 CYCLE ENGINE - The engine has

been pre-set to run at 3600 RPM.

Turn high speed adjustment needle

(B), Figure 11, to regulate flow of

gasoline to the engine. For com

plete adjustment procedure, refer to

Engine Manual.

IMPORTANT

When closing adjusting needles,

close finger tight only. Forcing may

cause damage.

2 CYCLE ENGINE

- The engine has

been pre-set to run at 4300 RPM.

Through opening (C), Figure 12, in

hand side of machine, turn the

mixture adjusting screw (D) (using

a screwdriver) to regulate flow of

f u e l t o

the engine.

IMPORTANT

Do not force screw tight. Damage to

carburetor or screw could occur.

Refer to Engine Manual for com

plete adjustment procédure.

IMPELLER CLUTCH ADJUSTMENT

(for models so equipped)

Adjust cable (E), Figure 13 up or

down by moving chain (F) one-half

line (one loop) at a time. If impeller

doesn’t rotate when engaged,

unhook chain, pull up on cable and

rehook chain in next lower loop. If

impeller rotates without engaging,

unhook chain and rehook chain in

10

next highest loop. Repeat proce

dure until proper adjustment is

achieved.

PADDLE REPLACEMENT

If paddles become worn and fail to

propel the snow thrower, replace

ment may be necessary. Replace all

3 paddles, one at a time. STOP

ENGINE.

1. Remove screws (G), Figure 14,

that secure paddle (H) to Impeller

frame (I).

2. Remove old paddle.

3. Install new paddle and secure it

to impeller using the same screws

and hex nuts used to secure old

paddle.

4. Repeat procedure for other

paddles.

BELT ADJUSTMENT - MODELS

225, 225E, 300 & 300E

If the Idler pulley does not apply

enough tension to belt to drive

impeller, adjust belt as follows:

1. Remove drive cover. Remove

the (8) screws (A & B) shown in

Figure 16. Two plugs, in cover, must

be removed to reach screws (A).

2. Remove anchor screw (Q), Fig

ure 15, and reinstall screw in low

position shown in Figure 15.

NOTE

Spring must never be stretched

(measured from end to end) more

that 3" (76 mm), if necessary, repo

sition anchor screw to position "X",

Figure 15.

3. Reinstall drive cover.