Furnace circuits, Blower motors, Fan control switch – Bard 2100-066 Rev. A User Manual

Page 6: Furnace circuits blower motors fan control switch, Electrical system components

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Electrical System Components

Furnace Circuits

All circuits within the oil firmaces are designed and wired in

accordance with Underwriters Laboratories’ requirements. They

have been inspected and tested at the factory to qualify for the UL

label which is attached to the furnace.

All circuits within the gas firmace are designed and wired in

accordance with American Gas Association requirements. They

have been inspected and tested at the factory to qualify for the

AGA Label which is attached to the furnace.

Black

White

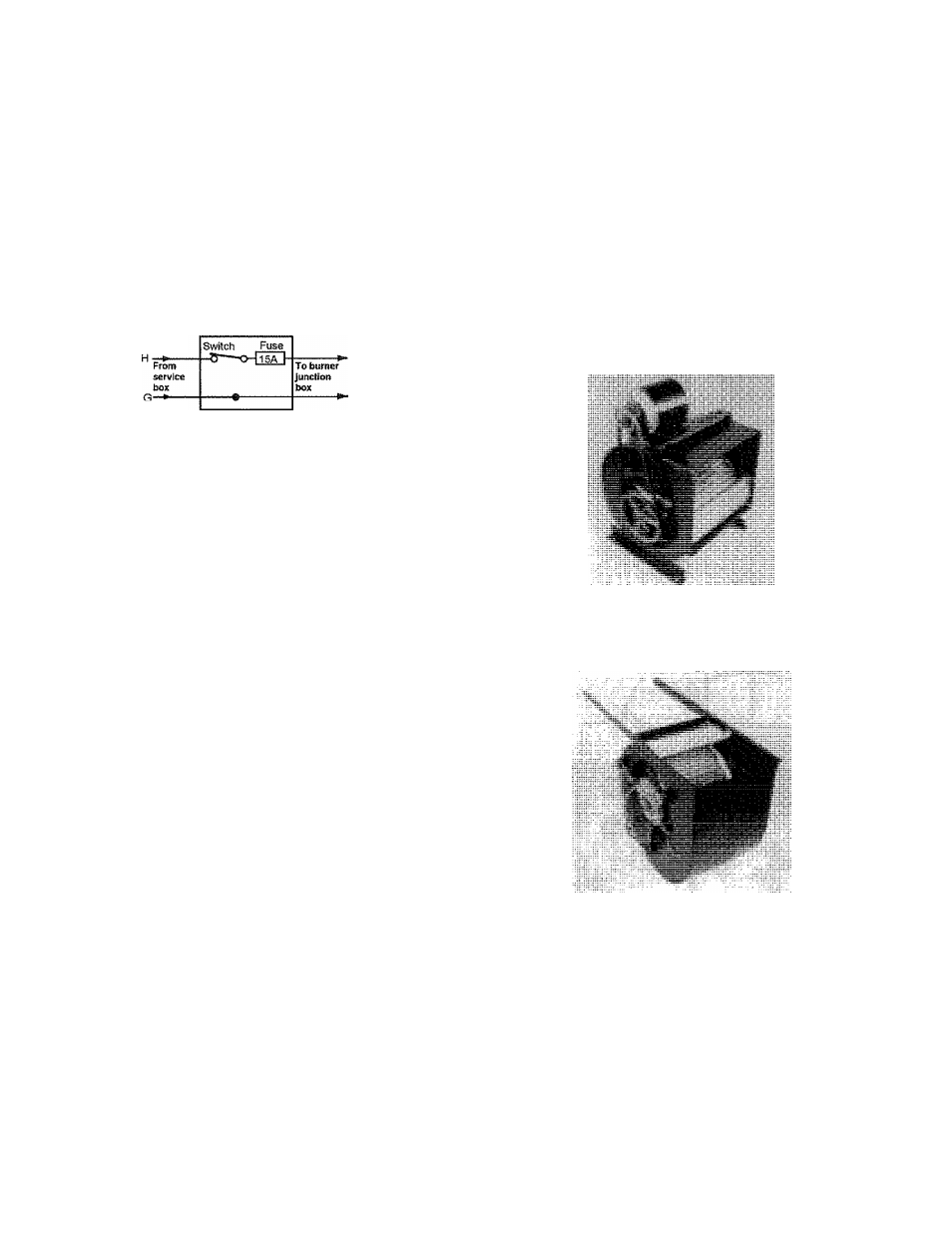

Fused switch box

All switching within the furnace line voltage circuits is done in the

hot 120V leg. The reason is that switching, if done in the ground

leg, could result in an unsafe grounding fault. See diagram.

Switch open, furnace

does not run, fuse blows_

when switch closes

Short to

ground

X

Gi|(-

To

furnace.

Switch in hot leg

Right

Wrong

Switch in ground leg

G.||-

Switch open

furnace runs

fuse does not blow

To

furnace

ground

The first load in all forced warm air systems is the blower motor

which is always line voltage. Therefore, the fiimace blower motor

is the first electrical component wired into the system.

Now when the disconnect switch lever is closed to the “on”

position, this will make a complete circuit and energize the

blower motor. This motor, in turn, drives the blower which

delivers the air through the furnace and duct system. When

the lever is placed in the “off” position, the circuit is not complete

and the blower motor will not run. Airflow in the system will stop.

The fuse in the switch is placed there to monitor the amount of

current flow in the circuit. If there should be excessive current

flowing in the circuit, the fuse will bum out and open the circuit.

Blower Motors

At this point, the blower motor has been wired into the circuit. This

is the basic circuit shown in the wiring diagrams. However, there

are variations in the blower motors used and the way they are

connected electrically. These variations and the reasons for each are

discussed in Manual 2100-058, “Basic Electricity.”

The type and size of blower motor installed in a fiimace depends

upon flie blower load required to deliver the correct amount of air to

the heating system. Because the heating system varies from one

installation to another, the blower speed needs to be adjustable to

match the needs of the air distribution system. This speed

adjustment may be done either mechanically or electrically.

The motor may be connected to the blower by a belt and pulley. In

this case, the speed adjustment is accomplished mechanically by a

change in the pulleys. This is referred to as a “belt-drive blower.”

Or the blower wheel may be mounted directly on the motor shaft.

In this case, the motor speed must be changed electrically. This is

referred to as a “direct-drive blower,”

Fan Control Switch

One of the major controls in the line voltage circuit will be the fan

control. The fan control switch is a heat-actuated switch which is

equipped with normally open contacts. It contains a bi-metal type

of heat sensing probe which senses the temperature of the air

passing from the furnace into the system.

The furnace illustration shows the location of the fan control in an

upflow type fiimace. The probe is usually a “spiral” type and is

installed into the heating unit on the front side of the cabinet with

the bimetal probe inserted through the cabinet into the heat

exchanger portion of the furnace. Its position must be such that the

bimetal probe can sense the temperature of the air passing from the