Post-service checks, Heat section checks, Post-service checks heat section checks – Bard 2100-066 Rev. A User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3. Motor bearings with oil cups or holes. Add a few drops of

automotive 10 nondetergent oil.

□ Check blower wheel bearings for wear.

1. Grasp blower pulley and move in up and down directions.

Also push in and out. There should be no movement in any

direction if the pulley is mounted tightly to the blower shaft.

2. Grasp shaft and test bearings on opposite side of blower

wheel. There should be no movement.

3. If there is in and out movement on either side, move locking

collars on the affected side closer to bearing as follows:

On the pulley side, loosen set screw on shaft and

remove pulley.

Loosen collar set screw and move collar snugly against

bearing housing. Tighten collar setscrew.

4. If there is still movement, bearings are worn. Inform

customer of bearing condition. If problem is severe, blower

bearings should be replaced. Notify service manager.

□ Lubricate blower wheel bearings.

1. Bearings with no lubricant fittings. These are permanently

sealed and lubricated and require no service.

2. Bearings with grease cups, Turn grease cup down

approximately one turn yearly. When cups are turned to the

bottom, refill with lubricant.

Bearings with grease plugs. These are normally prelubricated

and require lubrication about every two years. If lubricant is

required, use No. 2 neutral mineral grease. Check lubrication

instruction.

□ Clean blower and compartment.

1. Remove dirt from air scoops or vanes of blower wheel. This

may be done with moist rag or vacuum.

2. If blower is excessively dirty, it should be removed and

thoroughly washed/cleaned using high pressure hose.

Remove motor from blower assembly before washing blower.

Make sure motor is completely dry before it is put back into

operation.

□ Check blower wheel for free and balanced rotation.

1. Spin wheel. If wheel is badly out of balance or hits against

housing, blower should be replaced.

2. If dislodged balance weights are found, place them in exact

location they formerly occupied. Look for scratches on blades

to show where weight clip was attached.

When wheel is spun, the heavier side will fall to bottom, This

means the side minus the weight is probably on top. If old

location cannot be found, leave weights off rather than risk

further imbalance by incorrect placement,

3. If blower was removed from unit for cleaning, reinstall at

this time.

□ Check pulley alignment,

1, Cheek alignment by placing a straight rod across grooves of

the motor and blower pulleys.

2. If grooves of pulleys do not line up, loosen shaft setscrew and

move motor pulley until it is aligned with blower pulley,

3. Tighten motor pulley setscrew and recheck alignment.

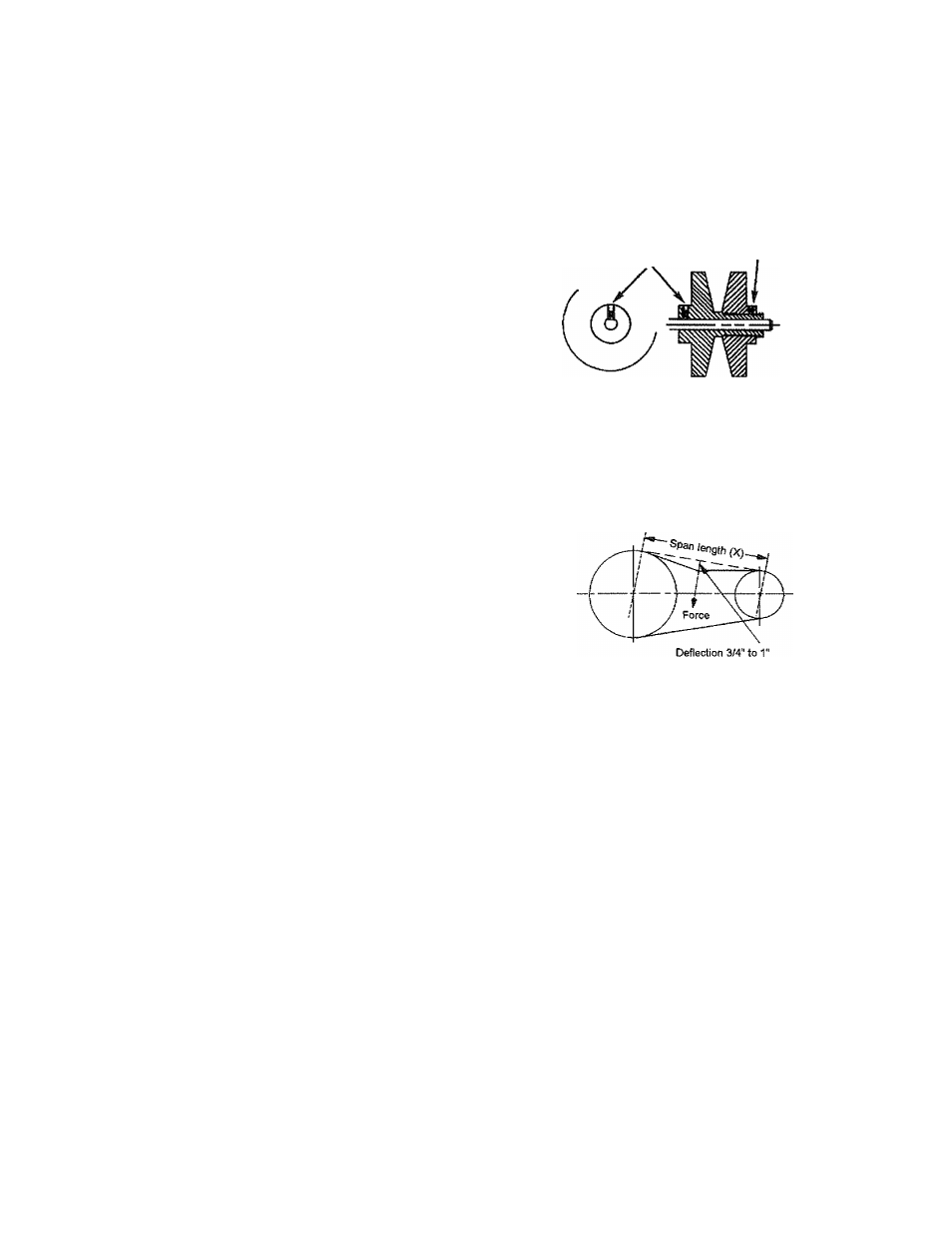

□ Check motor and blower pulley setscrews for tightness.

An adjustable motor pulley has two setscrews, one to tighten

the adjustable pulley sheave and one to tighten the pulley to

the motor shaft.

Set screw to tighten

pulley on motor shaft

Set screw to tighten

adjustable sheave

□ Put belt back on blower and motor pulleys and check

belt tension.

1. Place belt around pulleys.

2. Adjust motor mount to tighten belt.

3. Check tension by pushing down on belt halfway between

pulleys. Belt should move or deflect from 3/4" to 1".

4. When proper tension is obtained, tighten adjustable motor

mount.

□ Check all blower housing and motor mounts for tightness.

Post-Service Checks

□ Return theimostat(s) to original setting(s) recorded at beginning

of service call,

□ Leave copy of completed check sheet with customer.

□ Power on before leaving.

1. Be sure unit disconnect has been turned on before leaving to

avoid a needless, time consuming callback.

□ Leave all service areas neat and clean.

Heat Section Checks

These are discussed individually, according to type of fuel used, in

the next sections.

12