Mimntenance, Lubrication, Engine – MTD 242A641-000 User Manual

Page 6: Cleaning, Removing the flail screen, Engine oil, Air cleaner, Spark plug, Clean the engine

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

IMPORTANT:

There

is

a

flail

screen

located

inside

the

housing

in

the

discharge

area.

If

the

flai

screen

becomes

clogged,

remove

and

clean

as

instrjcted

in

the Maintenance section below.

For

best

performance,

it

is

important

to

k

shredding

blade

and

the

chipper

blades

shar

to Maintenance section, pages 7 and 8.

if

the

composition

of

the

material

being

dis^

changes

(becomes

stringy,

etc.)

or

if

the

rate

the

material

is

discharged

slows

down

consid(

is

likely

that

the

shredding

blade

and/or

blades

are

dull

and

need

to

be

sharpe

replaced.

3ep

the

D. Refer

charged

at which

irably,

it

shipper

ned or

MiMNTENANCE

A

WARNING: Always stop engine end dis

connect spark plug wire before cleaning,

lubricating or performing any repairs or

maintenance.

LUBRICATION

Lubricate

the

pivot

points

on

the

chute

defleotor

and

chipper chute door once a season using a light oil.

ENGINE

Refer

to

the

separate

engine

manual

for

engine

main

tenance instructions.

Maintain

engine oil

as

instructed

in

the

separate

engine

manual

packed

with

your

unit.

Read

and

follow

instructions carefully.

Service

air cleaner

every 25 hours under normal con

ditions.

Clean

every

few

hours

under

extreme

ly

dusty

conditions.

Poor

engine

performance

and

’looding

usually

indicates

that

the

air

cleaner

should

be

ser

viced.

To

service

the

air

cleaner,

refer

to

the

separate

engine manual packed with your unit.

The

spark plug

should be cleaned and the gap reset

once

a

season.

Spark

plug

replacement

is

recom

mended

at

the

start

of

each

season;

checl<

engine

manual for correct plug type and gap specifications.

Clean the engine

regularly

with

a

cloth

o'

brush.

Keep

the

cooling

system

(blower

housing

area)

clean

to

permit

proper

air

circulation

which

is

essantial

to

engine

performance

and

life.

Be

certain

to

re

nove

all

dirt and combustible debris from muffer area.

CLEANING

The

shredder

may

be

cleaned

by

running

water

from

a

hose

through

the

hopper

assembly

and

chipper

chute

with

the

engine

running.

Allow

the

shr

adder

to

dry thoroughly.

Wash

the

bag

periodically

with

water.

Allow

to

dry

thoroughly in the shade. Do not use heat.

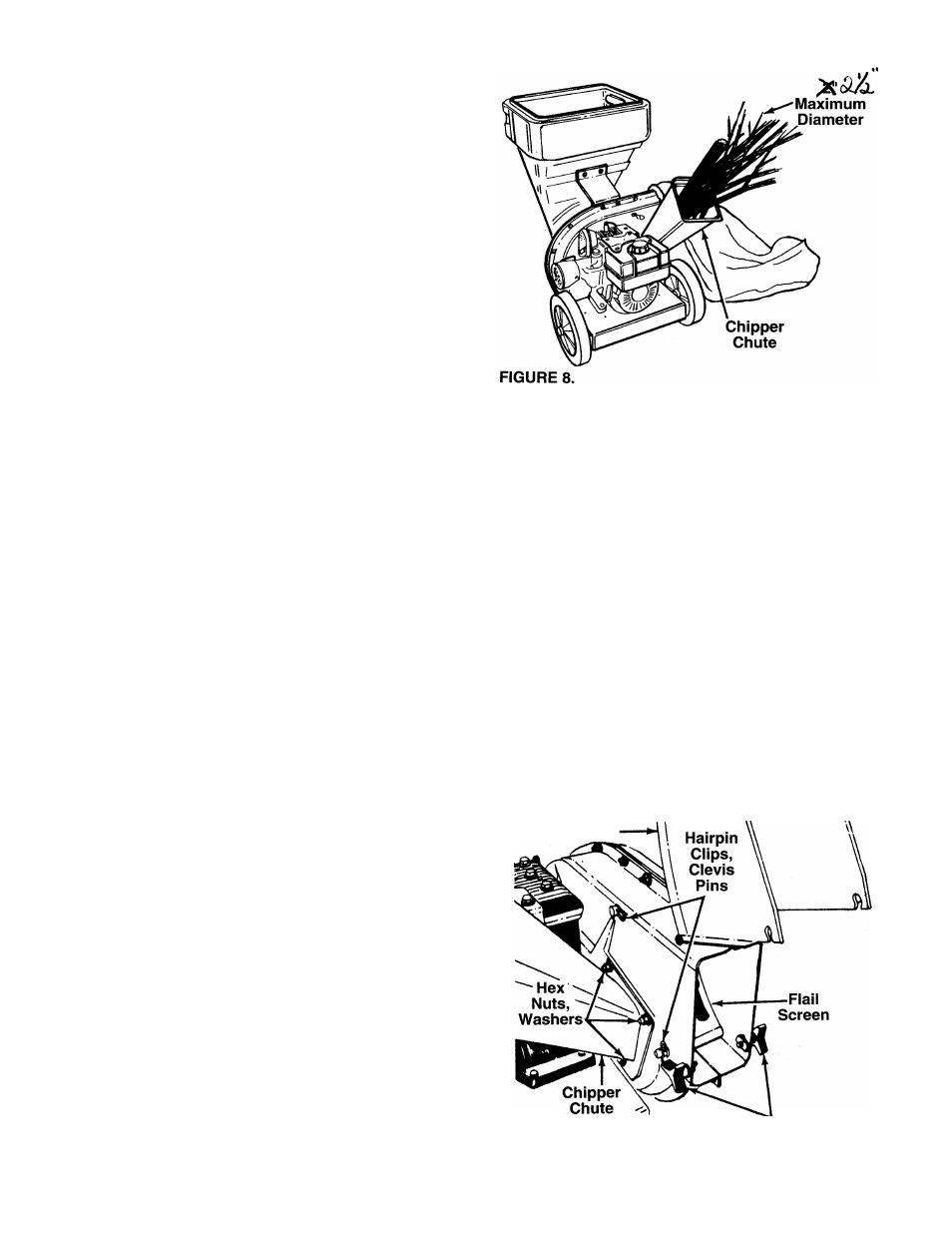

REMOVING THE FLAIL SCREEN

If

the

discharge

area

becomes

clogged,

remove

the

flail screen and clean area as follows.

1.

Stop

the

engine,

make

certain

the

shredder

has

come

to

a

complete

stop

and

disconnect

spark

plug

wire

from

the

spark

plug

before

unclogging

the chute.

2.

Loosen the two hand knobs on each side of the

chute

deflector.

Lift

the

chute

deflector

up,

and

tie

it out of the way.

3.

Remove

two

hairpin

clips

from

the

clevis

pins

which

extend

through

the

housing.

Remove

the

clevis

pins.

Lift

the

flail

screen

from

inside

the

housing. See figure 9.

4.

Clean

the

screen

by

scraping

or

washing

with

water. Reinstall the screen.

NOTE: Be certain to reassemble the flail screen with

the curved side down as shown in figure 9.

Chute Deflector

FIGURE 9.

Hand Knobs