D. chain tension – Poulan 3300 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

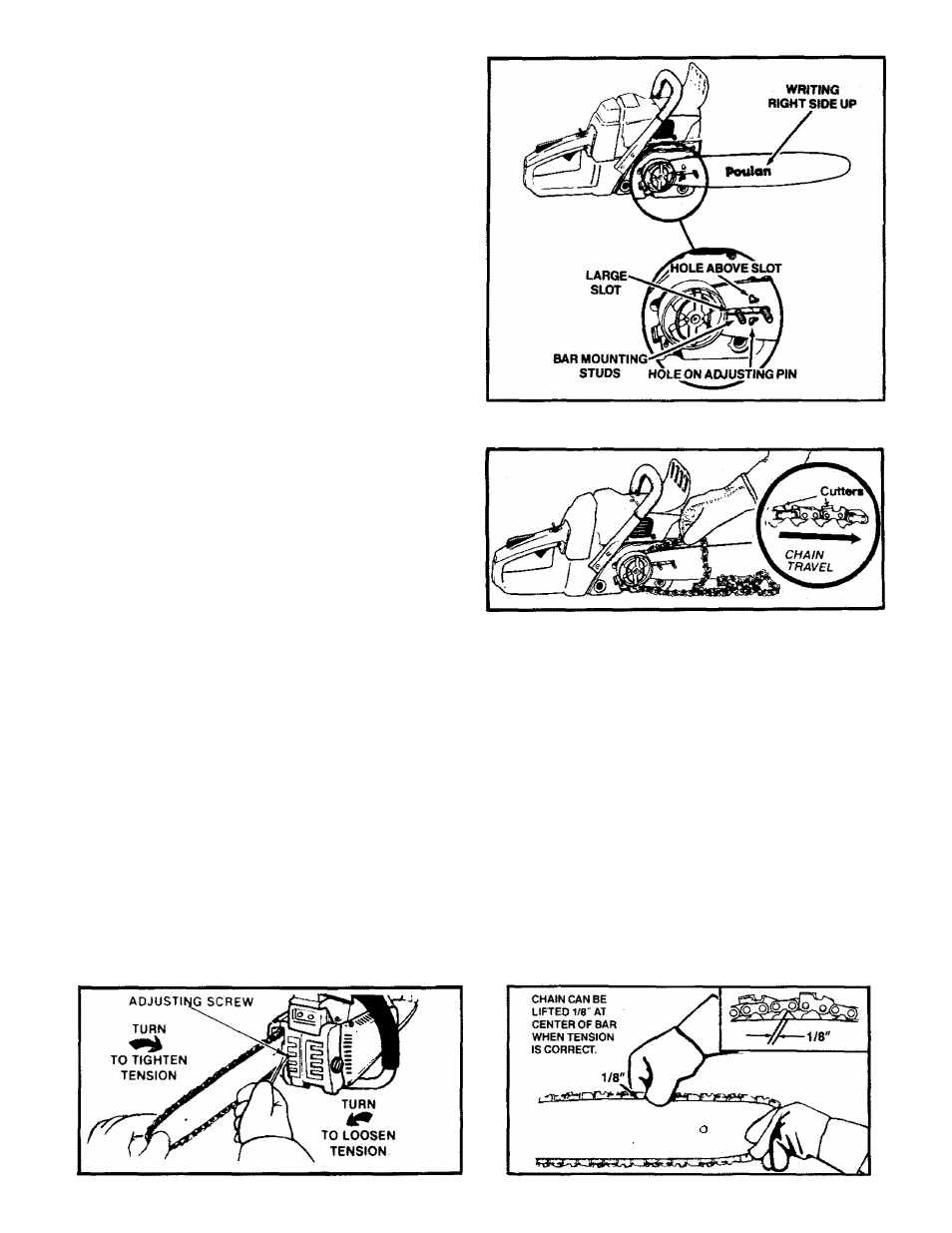

3.

Mount the guide bar. Mount the slotted end of the

guide bar overthe bar studs and the hole under the

slot on the adjusting pin. Figure 7.

4, Hold chain with cutters facing as shown in Figure 8.

5.

Place chain over and behind the clutch drum onto

the sprocket and fit the bottom of the drive links

between the teeth in the sprocket.

Start at the top of the bar and fit the chain drive links

into the groove around the guide bar. Figure 8.

Figure?

7.

Turn thè adjusting screw clockwise

until the

chain is snug in the guide bar groove. Figure 9.

8.

Install the bar clamp, replace the bar mounting

nuts, then tighten the nuts finger tight only.

9.

Follow “Chain Tension" instructions below.

Figures

D. CHAIN TENSION

• Correct chain tension is very important:

—a loose chain will wear the bar and itself.

— aloosechain canjumpoff the bar while

you are cutting.

— alight chain can damage the saw and/or

break.

• The chain stretches during use, especially

when new. Check tension:

— each time the saw is used

— more frequently when the chain is new

— as the chain warms up to normal operating

temperature

• Chain tension is correct when the chain:

— can be lifted about 1/8" from the guide bar at

a point near the middle of the bar, and

— will move freely around the bar.

Chain tensioning procedure:

NOTE: The bar clamp nuts must be no more than

finger tight to tension the chain correctly.

Hold the tip of the guide bar up and turn the adjusting

screw just until the chain does not sag beneath the

guide bar. Figure 11.

1

NOTE:Turn screw clockwise •

Turnscrew counterclockwise i

k to tighten tension,

»toloosentension.

2 Check the tension by lifting the chain from the guide

bar at the center of the bar. Figure 12.

3. Continue turning the adjusting screw until the tension

is correct.

4. Hold the tip of the guide bar up and securely tighten

the bar clamp nuts with the scrench.

5. Recheck tension. See Figure 10-

Figured

Figure 10