D. carburetor adjustments – Poulan 3300 User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

D. CARBURETOR ADJUSTMENTS

• Poor engine performance can be a result of other

causes such as dirty air filter, carbon buiid-upon

muffler outlets, etc. See “TVouble Shooting

Chart” before proceeding with carburetor

adjustments.

•

Fbrthe best results, Beaird-Poulan recommends

that you have a qualified service dealer make all

carburetor adjustments.

Yourdealer hasthetrain-

ing, experience and tools necessary to properlyadjust

your saw to meet our factory performance specifica

tions. This service Is not covered by warranty. If it

becomes necessary for you to make carburetor

adjustments yourself, followthe described procedures

very carefully.

• The carburetor has been adjusted at the factory

for sea level conditions.

Adjustments may become

necessary if the unit is used at significantly higher

altitudes or if you notice any of thefollowing conditions;

NOTE:

Be sure to properly prepare the saw as

described in “1. Preparation” below, before making

any adjustments.

— Chain moves when the engine runs at idle

speed. See ”2. Idle Speed Adjustment.”

— Saw will not idle. See “2. Idle Speed Adjust

ment” and “3. Low Speed Mixture Adjust

ment.”

— Engine dies or hesitates when it should accel

erate. See “4. Acceleration Adjustment.”

— Loss of cutting power which is not corrected

by airfiltercleaning. “See "5. Highspeed Mix

ture Adjustment.”

ICAUfiON:! Permanent damage will occurto any

2-cycle engine if incorrect carburetor adjust

ments are made.

• If theunit will not operate properly after making

these adjustments, take the unit to a qualified

service dealer.

______

A WARNING

The chain will be moving during mostof thisprocedure.

Wear your protective gear and observe all safety

precautions.

1. PREPARATION

a. Stop engine.

b. Use a fresh fuel mixture with proper gasoline/

oil ratio.

c. Place the saw on a solid, flatsurfaceand makesure

the chain will not contact any object.

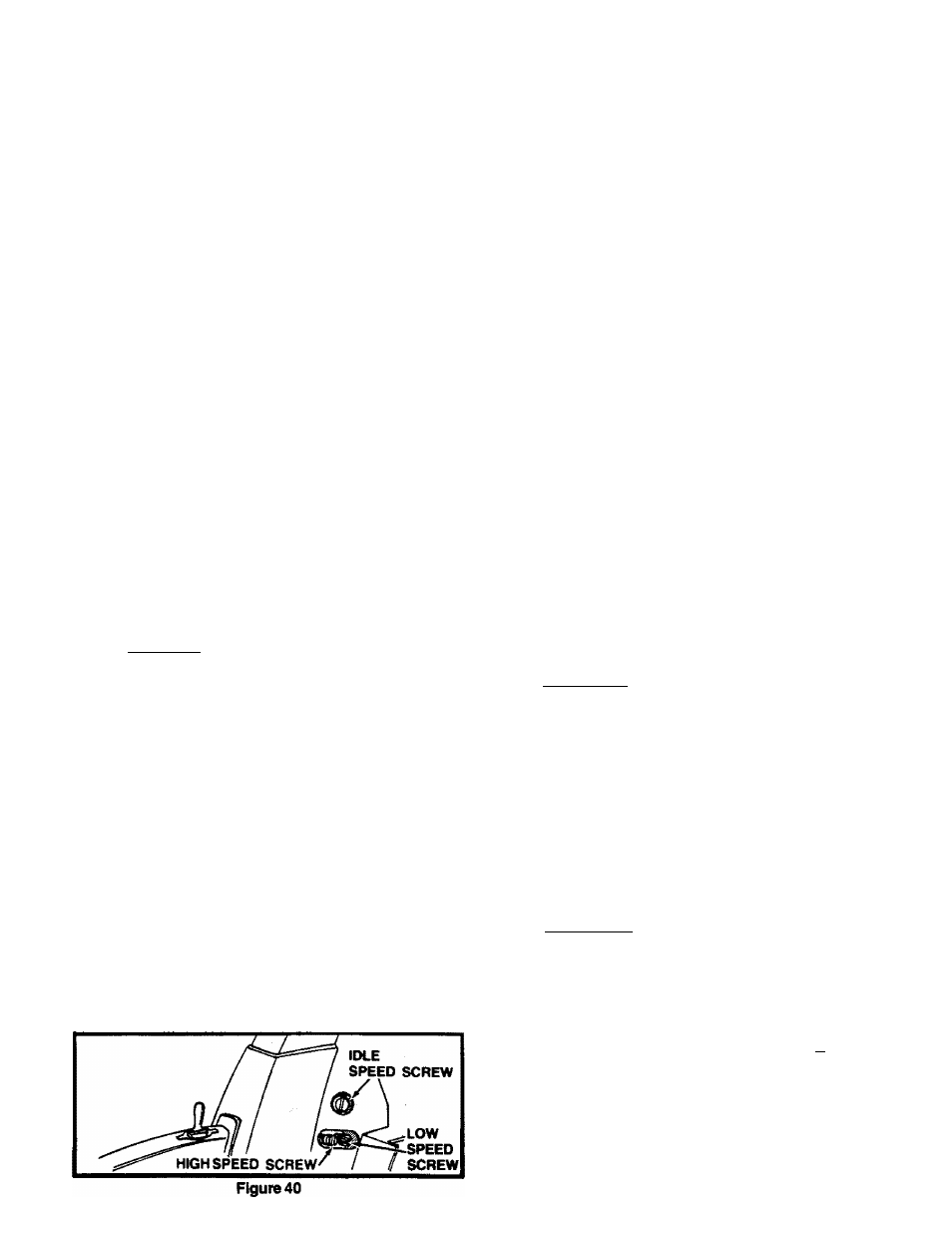

d. Locate the three (3) carburetor adjusting screw

openings to the right oftheairfilter cover. Figure 40.

e. Start the engine and allow engine to idle 3 minutes

to warm up. The engine must be at operating

temperature for proper adjustments to be made.

2. IDLE SPEED ADJUSTMENT

a. Allow engine to idle.

b.

AdjustIdleSpeedScrewuntilenginecontinuesto

run without stalling and without the chain moving.

— Turn screw clockwise

to increase

engine speed if engine stalls or dies.

— Turn screw counterclockwise

to slow

engine down and/or to keep the chain from

turning.

c. No further adjustments are necessary if the

chain does not move at idle speed and if perfor

mance is satisfactory.

A

warning

Recheck idle speed after each adjustment below. The

chain must not move at idle speed to avoid serious

injury.

3. LOW SPEED MIXTURE ADJUSTMENT

a. Allow engine to idle.

b Turn the Low Speed Mixture Screw slowly

clockwise A until the RPM starts to drop.

Note the position,

c. Turn the Low Speed Mixture Screw counterclock

wise

until the RPM speeds up and starts

to drop again. Note the position.

d. Set the Low Speed Mixture Screw at the mid

point between the two positions.

4. ACCELERATION ADJUSTMENT

If engine dies or hesitates instead of accelerating, turn

the Low Speed Mixture Screw 1/16 of aturn at a time

counterclockwise

until

you

have

smooth

acceleration.

5. HIGH SPEED MIXTURE ADJUSTMENT

I

CAUTION-1 Adjustments as small as 1/16 of a

turn can affect engine performance. It is impor

tant to turn the screw only 1/16 of a turn per adjust

ment and test the performance of the saw before

making further adjustments.

a. Make a test cut.

b. Adjust the High Speed Mixture Screw 1/16ofaturn

as follows:

— Clockwise if saw smokes or loses power,

— Counterclockwise

if the saw has speed

out of the cut but lacks power in the cut.

c. Repeat test cut.

d. Continue 1/16 of a turn adjustments until the saw

runs smoothly in cut.

I CAUTIONFI

a

too lean high speed setting (clock

wise

adjustment)

will

cause

engine

damage to any 2-cycle engine from overheating

and lackof lubrication. Never set the high speed

mixture screw so for clockwise that you

have high speed but lack power while cutting. An

effective approach follows:

—

Turn

screw

counterclockwise

A

until

engine loses power while cutting.

— Then, turn screw clockwise wHk in 1/16 of a

turn increments

only until the engine has

power while cutting.

NOTE: If the unit will not operate properly

after

making these adjustments, take the unitto a qualified

service dealer.

19