B. spark arrestor and spark plug, M m m ïï – Poulan 3300 User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5.) Correct Depth Gauges

a.) Place depth gauge tool over each cutter

depth gauge. Figure 31.

File level with the flat file if depth gauge is

higher than the depth gauge tool.

Maintain rounded front corner of depth

gauge with a flat file. Figure 31 &32.

NOTE:

The very top of the depth gauge

should be flat with the front half rounded

off with a flat file.

b.)

c.

A

warning

Depth gauge tool is required to insure proper depth

gauge. Filing the depth gauge too deep will increase

the chance of kickback which can result in serious

injury.

b. CHAIN REPLACEMENT

1.

) Useonly the Low-KickChaIn specified for

your saw in “Specifications,” forrepiace-

ment chain.

2. ) Replace the chain when cutters or links

break.

3. ) See a qualified service dealer to replace

and sharpen individual cutters for match

ing your chain.

4. ) Always have a worn sprocket replaced by

a qualified service dealer when installing

a new chain to avoid excessive wear to the

chain.

GUIDE BAR MAINTENANCE

•

Conditions which can require guide bar

maintenance:

— saw cuts to one side

— saw has to be forced through a cut

— inadequate supply of oil to bar and chain.

•

Check the condition of theguidebareachtime

the chain is sharpened.

A worn guide bar will

damage the chain and make cutting more difficult.

• Replace the guide bar when:

— the inside groove of the guide bar rails is

worn.

— the guide bar is bent or cracked.

e

Use only the Reduced-Kickback Guide Bar

specified for your saw In "Specifications,” for

replacement.

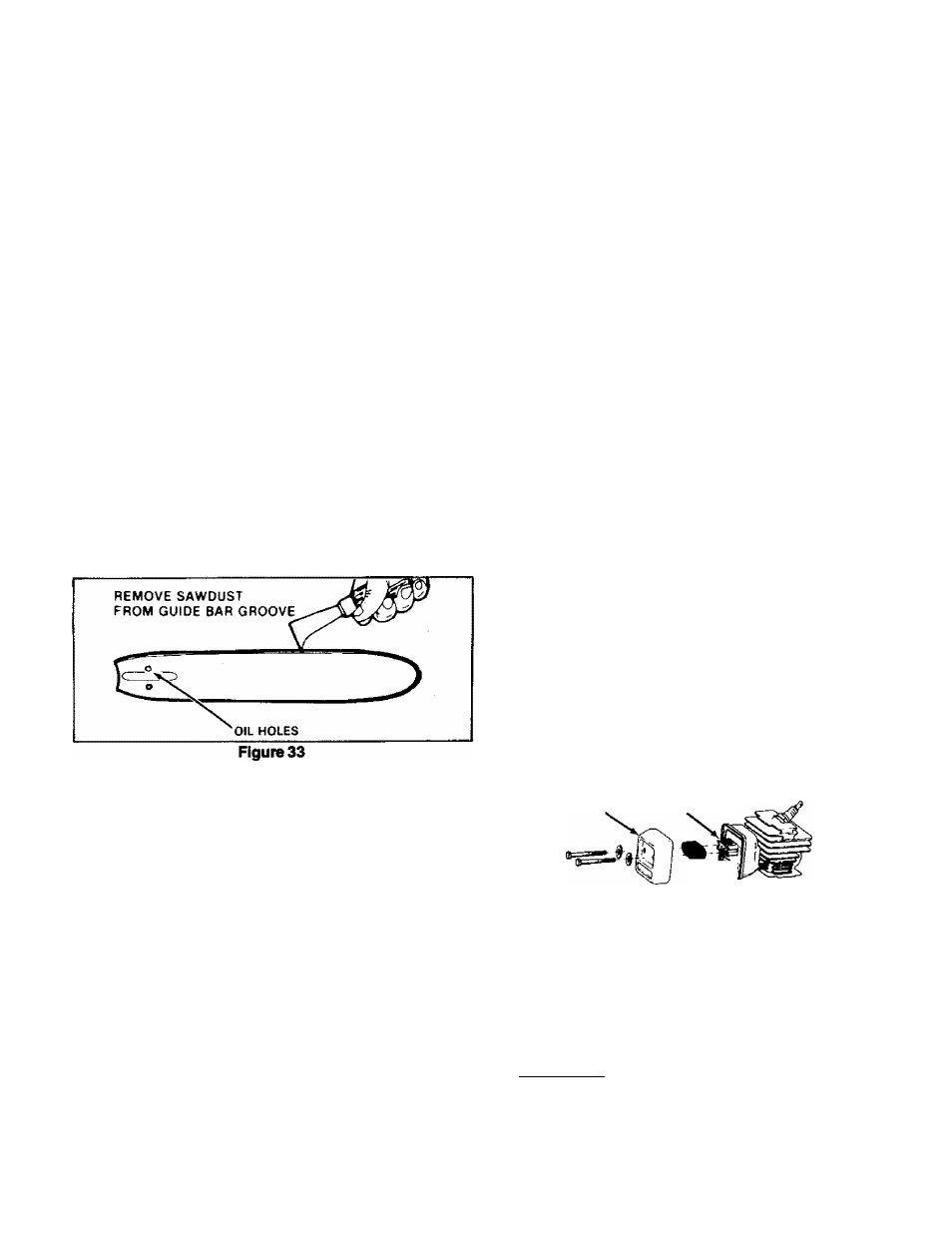

a. Remove the guide bar to service.

b.

Clean oil holes at least once for each five

hours of operation. Figure 33.

c.

Remove sawdust from the guide bar

groove periodicaily with a putty knife or

a wire. Figure 33.

d.

Remove burrs by filing the side edges

of the guide bar grooves square with a

flat file. Figure 34.

e. - Restore square edges to an uneven rail

top by filing with a flat file. Figure 34.

M M M ÏÏ

1

CORRECT

GUIDE BAR

GROOVE

WORN GROOVES

FILE

EDGES'

SQUARE

Figure 34

B. SPARK ARRESTOR AND SPARK PLUG

1. SPARK ARRESTOR

• Carbon deposits build up on the spark ar

restor,

as the saw Is used and must be removed to

avoid creating afire hazard or causing engine dam

age.

• Replacethesparkarrestorif breaks occur.

• Keep the spark arrestor clean at all times.Clean.

— as required

— at least once for each 25-30 hours of

operation

Items required:

— wire brush,

— 3/8" wrench

a. Disconnect the spark plug wire.

b. Remove the heat shield. Figure 35.

c. Remove the screen from the diffuser.

d. Clean the screen with a wire brush or replace if

breaks are found.

e. Reassemble parts.

HEAT SHIELD DIFFUSER

SPARK ARRESTOR! SCREEN

Figure 35

2. SPARK PLUG

• Replace the spark plug when necessary;

• If you perform this maintenance yourself, note

the “Caution” below.

I

CAUTION:

i

Do not mix chrome-colored fan

housing screws with the black-colored cylinder

shroud screws. Other than color, these screws are

similar in appearance; but if interchanged, they

can strip out and/or cause permanent engine

damage.

17