R bar and chain lubricant, Use the following, How to fill the oil tank – Poulan 3300 User Manual

Page 10: Adjusting the automatic oiler, Important points to remember, F. bar and chain lubricant

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

R BAR AND CHAIN LUBRICANT

•

The Guide Bar and Cutting Chain require

continuous lubrication in order to remain in

operating

condition.

Lubrication

is

provided

by the automatic oiler system when the oil tank

is kept filled.

—Lack of oil will quickly ruin the bar and chain.

—Too little oil will cause overheating

shown by

smoke coming from the chain and/or discolora

tion of the guide bar rails.

•

Genuine Poulan® Bar and Chain Oil is recom

mended to protectyour unit against excessive

wear due to heat and friction.

Poulan® lubricant

resists high temperature thinning. If Poulan® bar

and chain oil is not available, use a good grade SAE

30 oil. Never use waste oil for this purpose.

•

In freezing weather oil will thicken, making

it necessary to thin bar and chain oil with a

small

amount

of

Diesel

Fuel

#1

or

Kerosene.

Bar and chain oil must be free flow

ing for the oil system to pump enough oil for ad

equate lubrication.

1. USE THE FOLLOWING :

30Forabove —lubricant—undiluted,

30 -0 F —95% lubricant to 5% Diesel Fuel

#1 or Kerosene.

Below 0 F — 90% lubricant to 10% Diesel

Fuel #1 or Kerosene.

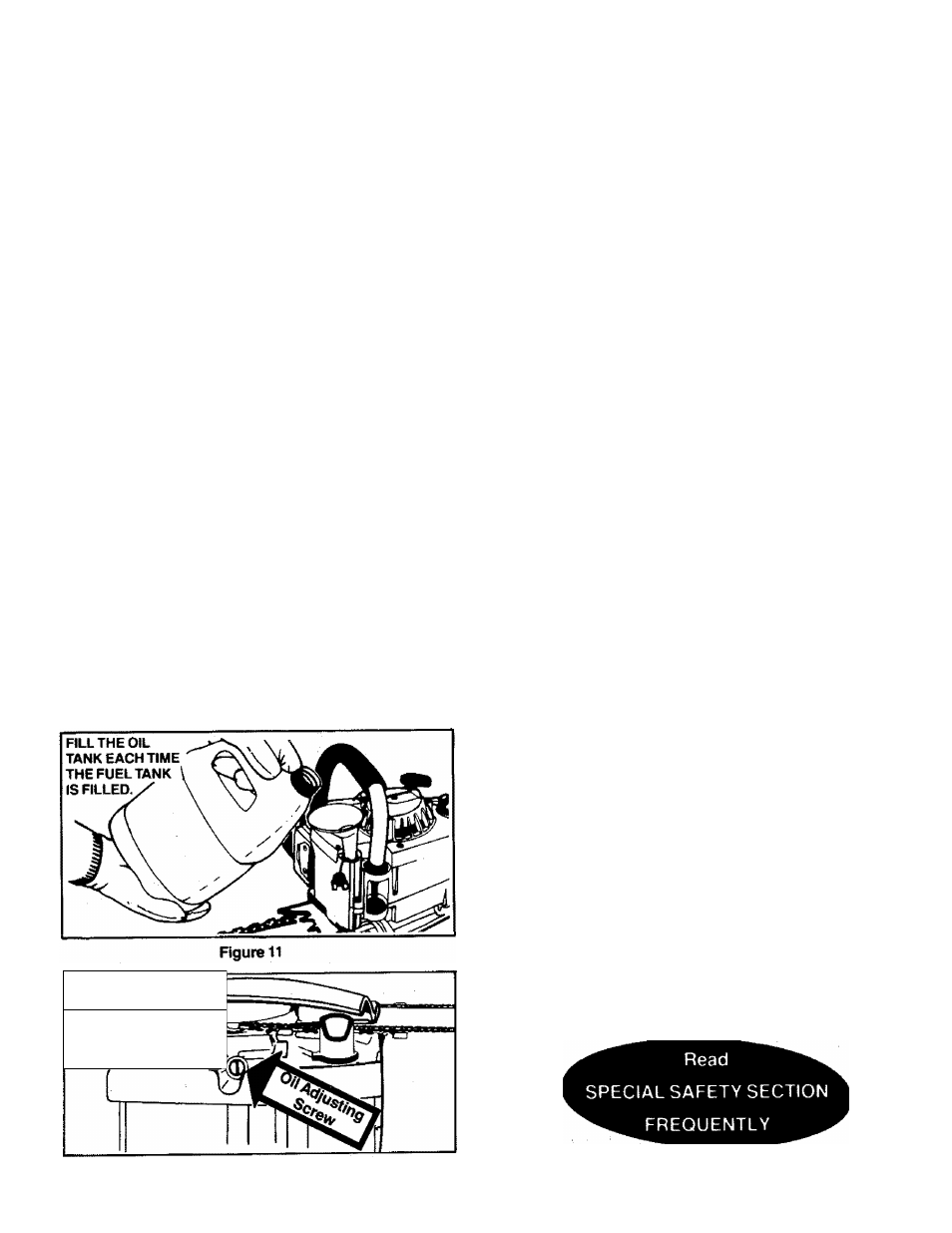

2. HOW TO FILL THE OIL TANK

a. Stop the engine.

b. Turn saw on its side with oil cap up. Figure 11.

c. Loosen cap slowly and wait for pressure in the

tank to be released before removing the cap.

d. Fill the oil tank.

e. Fieplace the oil cap securely.

OIL ADJUSTING

SCREW

J

3. ADJUSTING THE AUTOMATIC OILER

• The ad]ustable automatic oiler is set for max

imum output at the factoiy. Some types of

cutting will require adjusting the oiler.

— less oil is required for soft or freshly cut

wood.

— maximum oil is required for hardwood or

vwod that has been cut for a period of time.

•

The adjusting screw

is located at the bottom of

the saw on the crankcase next to the bar clamp

housing and can be adjusted with the screwdriver

end of the scrench provided with your saw.

Figure 13,

— To Increase the oil flow,

turn the adjusting

screw counterclockwise .

— To decrease the oil flow,

turn the adjusting

screw clockwise .

•

If the oiler is adjusted to decrease the oii flow,

be sure to readjust the oiler before returning to

types of cutting that require greater lubrication.

•

When the saw is run at high RPM’s for long

periods of time during certain types of cut

ting, such as pruning or debranching

, more oil

can be delivered than is required. To avoid runn

ing out of chain oil before running out of fuel,

check the oil tank periodically.

4.

IMPORTANT POINTS TO REMEMBER

a Fill the oil tank each time you refill the fuel

tank

to ensure there will be sufficient oil for the

chain whenever you start and run the saw

b. Keep sawdust and debris cleaned from the

oil holes in the guide bar

to allow an adequate

oil flow to the bar and chain.

c. Keep spilled and spattered oil wiped from the

unit to avoid sawdust and debris build-up.

Pay

particular attention to oil on the fan housing and

starter assembly to avoid overheating the engine.

d It is normal for a small amount of oil to ap

pear under the saw after the engine stops.

This is due to oil draining from the bar and chain

when not in use.

Figure 12

10