Generac Power Systems MC User Manual

Page 35

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

RESULT:- Float Valve, Seat, Gasket and

Float level are good.........

Float Valve, Seat, Gasket or

Float level check bad........

-...Continue Diagnostic Tests

-Replace or adjust, then test

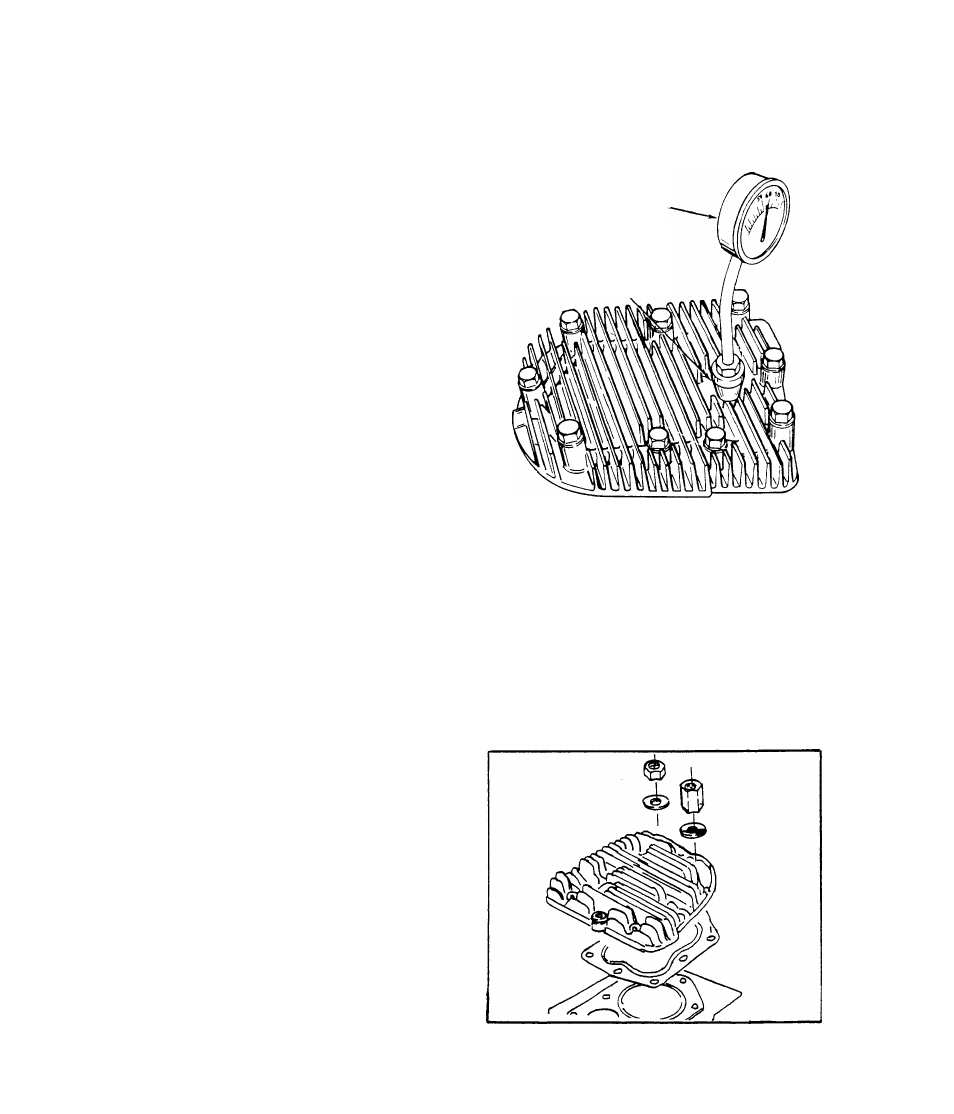

TEST 24:- COMPRESSION

A.)-Insert a standard compression

gauge into engine spark plug hole.

Open throttle wide open and crank

engine. Compression should be app

roximately 75-85 psi (cold) or 95-

105 psi (hot).

COMPRESSION

GAUGE

SPARK PLUG

REMOVED

RESULT:- Compression reading good...................... Go to Test 29

Compression reading low.......................Continue tests

B,)- Squirt a few drops of clean engine oil into spark plug hole on en

gine cylinder head. Repeat compression test. If compression reading is

higher than was obtained in Paragraph A, ring or cylinder wear is indi

cated, If little or no difference in compression was noted, trouble may

be due to head gasket leakage, worn valves, etc.

RESULT:- Noticeable increase in

compression obtained...............

Little or no increase in compression.

Go to Test 27

Go to Test 25

TEST 25:- HEAD GASKET

Crank the engine. A "hissing" sound

at the spark plug indicates the plug

is loose or broken. Likewise, "hiss

ing" at the cylinder head indicates

loose head nuts or a leaking head

gasket. Tighten loose spark plug, re

place broken spark plug using a new

plug gasket. If cylinder head leaks,

check for warped cylinder head and

for a defective head gasket. Refer to

engine section of manual and to TORQ

UE SPECIFICATIONS (SPECIAL).

2.2-13