Handle adjustment (model 405), Belt tension adjustment—drive and ti ie clutches, Note – MTD 218-402-000 User Manual

Page 10: Lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

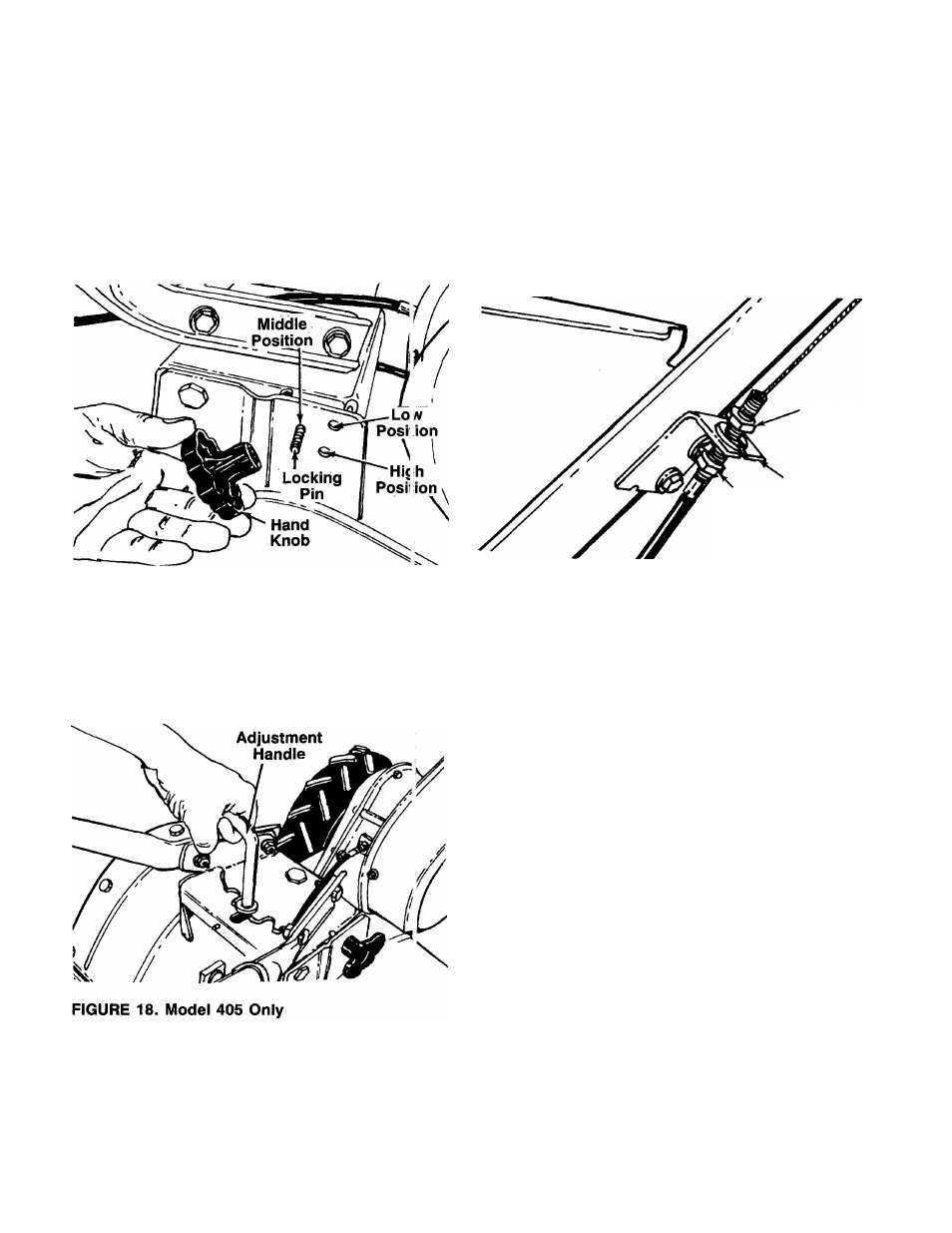

HANDLE ADJUSTMENT (Model 405)

The handle may be placed in one of nine differen posi

tions. The handle may be adjusted to one of three

height positions, and also may be adjusted to be n line

with the tiller, or swung to the left or right so the op arator

is not walking in the freshly tilled soil.

To adjust the handle height, remove the hand kno o and

locking pin shown in figure 17. Select one of the three

adjustment holes and reassemble.

FIGURE 17. Model 405 Only

To adjust the handle position from side to side, Ic osen

the adjustment handle by turning it counterclockwise

several turns. Pull the adjustment handle backward and

pivot the tiller handle to desired position. Releaso and

tighten the adjustment handle. See figure 18.

BELT TENSION ADJUSTMENT—Drive and Ti ie

Clutches

Periodic adjustment of the belt tension may be req jired

due to normal stretch and wear on the belt. Adjust Tient

is needed if the tines seem to hesitate while tillinc, but

the engine maintains the same speed.

To adjust, loosen the hex nuts at the cable bracket on

the handle. See figure 19. With the clutch lever re

leased as shown in figure 12, adjust the bottom nut so

that there is only a slight amount of slack in the control

wire. Tighten the upper nut against the bracket.

NOTE

Do not overtighten control wire.

Too much tension may cause it to

break.

Upper

Nut

Cable

Bottom Bracket

Nut

FIGURE 19.

CARBURETOR ADJUSTMENT

AC

WARNING

i

If any adjustments are made to the

engine while the engine is running,

(e.g.

carburetor),

disengage

all

clutches and tines. Keep clear of all

moving parts. Be careful of heated

surfaces and muffler.

Never make unnecessary adjustments. The factory set

tings are correct for most applications. If adjustments

are needed, refer to the separate engine manual

packed with your tiller.

LUBRICATION

Chain Cases—

The chain cases are pre-lubricated and

sealed at the factory. They require no checking unless

the chain cases are disassembled. To fill with grease,

lay the left half of the chain case on its side. Add 12

ounces of plastilube #0 grease to the tine chain case

or 10 ounces to the wheel chain case. Assemble the

right half to it. This grease can be obtained at your

nearest authorized dealer. Order part number

737-0133.

10