Assembly 217-100, Clutch control lever assembly, Check list before operation – MTD 219-250 User Manual

Page 4: Starting your tiller

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY 217-100

Your rotary tiller is shipped complete in a single carton.

The tines, wheels, handles, controls and depth bar are to be

assembled. This is done in the manner described below.

TINES

- Mount tines on tine shaft as shown. Tines must

be mounted with the cutting edges facing the front. The

tiller will not operate properly unless the sharpened sur

face of the tines enter the soil first. Secure tines in posi

tion on tine shaft with cap screws (47), and nuts (46).

NOTE:

Dust pads (68 8t 69) are provided in screw pack.

These must be assembled as shown.

WHEELS - Insert axle bolts (31) into wheel hubs. Secure

with locknuts (32) tightened only enough to allow free move

ment of the wheels (26). Attach wheel and axle assemblies

to outside of tiller legs (10 8t 11). Fasten with locknuts (32)

as shown.

HANDLE- Assemble the handle brackets (122) to the han

dle (116) with hex head screw (127), lockwashers (44) and

hex nuts (126). Do Not Tighten. Place the handle brackets

(122) in the tail piece slots. Fasten the lower hole in the

handle brackets to the frame with a carriage bolt 5/16

-18

X 3/4 Ig. (50), lockwasher (51) and hex nut (57). Tight

en all screws and nuts.

CLUTCH CONTROL LEVER ASSEMBLY

LOCKOUT LEVER-Place the hex head screw %-20 x 1

%

(128) through the hole in the tab below the slot in the han

dle panel from the right hand side. Assemble in this order:

Rubber washer, lock out rod (rod bracket to the front), steel

washer and lock nut. Tighten until rubber washer compresses

slightly.

CLUTCH CONTROL ASS’Y-

Screw the ferrule (120) on the

threaded end of the lock out rod (119) until about '/

2

” of the

threads show. Insert the ferrule through the control lever

(15), fasten with flat washer (123) and cotter hairpin (124).

Put the lockout handle in the neutral position. Insert the

lockout rod in the bracket on the lockout lever and secure

with a cotter hairpin through the center of the bracket. Ad

just the ferrule so both belts are slack when the lockout

lever is in the neutral position.

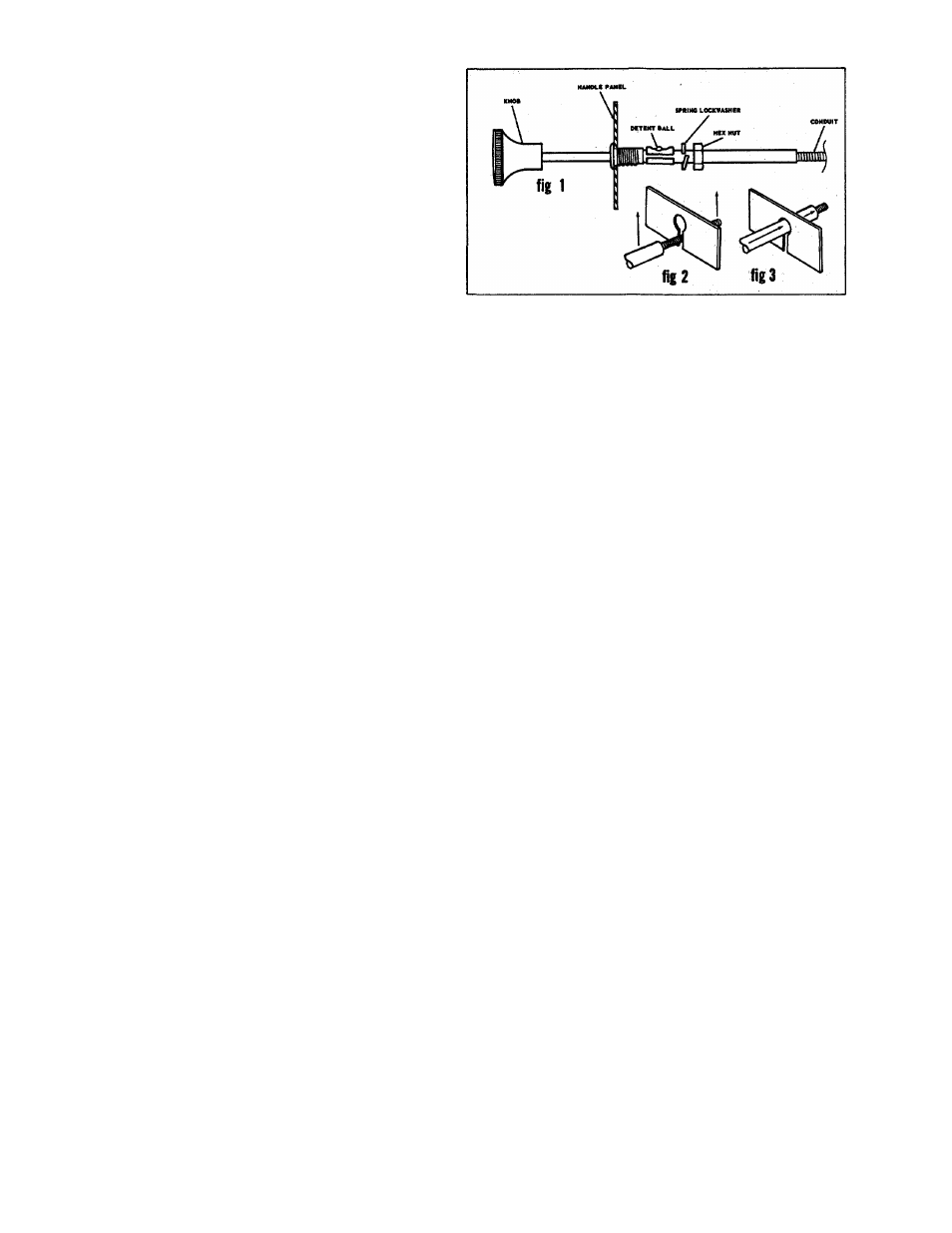

THROTTLE-T

o

assemble the throttle push the black plastic

knob in all the way then pull it out until the detent ball

clicks into the second notch. The knob will be pulled out

approximately 1—3/8” when in the second notch. In this po

sition the spring lockwasher and the hex nut will slide past

the detent ball. Place the conduit through the slot in the

handle panel (see fig 2) and push the unit (see fig 3) in until

it seats as shown (see fig 1). Secure with the spring lock

washer and hex nut.

OPTIONAL HANDLE

- Assemble handle panel (13) (small)

to handles as shown. Secure top portion with carriage bolts

(104) and locknuts (35). Secure bottom with cap screws (48),

lockwashers (44) and nuts (53). Assemble control handle

assembly (6). to panel with cap screw (106), spring (101),

washer (107) and locknut (35) as shown. Attach adjustment

tube (110) to control rod (19). Insert formed end of control

rod into control pivot lever (15) from left side. Fasten upper

end of control handle assembly with cap screw (112) and

locknut (113). Move throttle control knob out enough to allow

face washer to be loosened. Position control (64) into slot

in end of large panel. Tighten face washer. Fasten control

cable to handle with cable clip (67).

CHECK LIST BEFORE OPERATION

1. Check tiller tines for proper installation. With throttle

control lever set on “Stop” position and the clutch

control handle set in “Forward” position, slowly crank

engine to determine direction of tine rotation. Be sure

all tines are mounted so the sharpened edges enter the

soil first.

2. Check all nuts and bolts for proper tightness. This is

especially important during the initial operation period.

Make this same check periodically thereafter.

3. Check throttle control for proper setting. If choke control

on engine is not fully extended when the throttle control

lever is on “Choke” position, reset as shown in

ADJUSTMENT instructions, (4 H.P. only)

4. Check gear case for proper lubricant level. With tiller

on a level surface, lubricant level should be up to the

rear pipe plug opening. This can be checked by removing

rear pipe plug. Maintain correct lubricant level with

Molilube SAE 140 Gear Oil or equivalent. The gear case

holds five (5) ounces of lubricant.

5. Check fuel tank. Clean, fresh, regular gasoline should be

used at all times.

6. Check engine crankcase for proper oil level. The engine

is shipped without oil in the crankcase. Be sure to fill

crankcase before starting engine. Be sure crankcase

is FULL.

NOTE:

The engine is warranted separately by the engine

manufacturer. For warranty service contact the engine

manufacturer or their local authorized service station. All

important information pertaining to care and operation is

included in the engine manual.

STARTING YOUR

tiller

1. Be sure clutch control handle is in “Neutral” position.

2. Move throttle control lever to “Choke or Start” position.

3. After cranking the engine several times, or as the engine

fires, move the throttle control lever to run position.

4. Use “Choke” as needed to keep engine operating during

warm-up period on 4 H.P. model.

5. Adjust throttle control lever for desired operating speed.

6. To stop engine, move throttle control lever to “Stop”

position. Keep throttle control lever in “Stop” position

at all times when tiller is not in use.

FORM NO. 770-18820