5 maintenance, A warning, Tiller lubrication – Troy-Bilt PONY 664DM User Manual

Page 17: Check hardware, Check tire pressure, Maintenance, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section

UUÌUI ■ ■

■

■

5

Maintenance

A

WARNING

Before

inspecting,

cieaning

or

servicing the machine, shut off engine,

wait for aii moving parts to come to a

compiete stop, disconnect spark piug

wire and move wire away from spark

piug. Remove ignition key on eiectric

start modeis.

Faiiure to foiiow these instructions can

resuit in serious personai injury or prop

erty damage.

TILLER LUBRICATION

MAINTENANCE SCHEDULE

P R O C E D U R E _________________________ ...N O T E S ...

Check motor oil level

2 ,3

Clean engine

1J

Check drive belt tension

1 ,4

Check nuts and bolts

1 ,4

Change motor oil

1 ,4 ,6

Lubricate tiller

4

Service foam pre-cleaner air filter

(if so equipped)

7

Service paper air filter (if so equipped) 7

Check gear oil level in transmission

1 ,5

Check tines for wear

5

Check air pressure in tires

5

Service spark plug

7

NOTES

1

- After first 2 hours of break-in operation.

2

- Before each use.

3

- Every 5 operating hours.

4

- Every 10 operating hours.

5

- Every 30 operating hours.

6

- More frequentiy in dusty or dirty conditions.

7 - See Engine Owner's Manuai for service

recommendations.

8

- Whichever time intervai occurs first

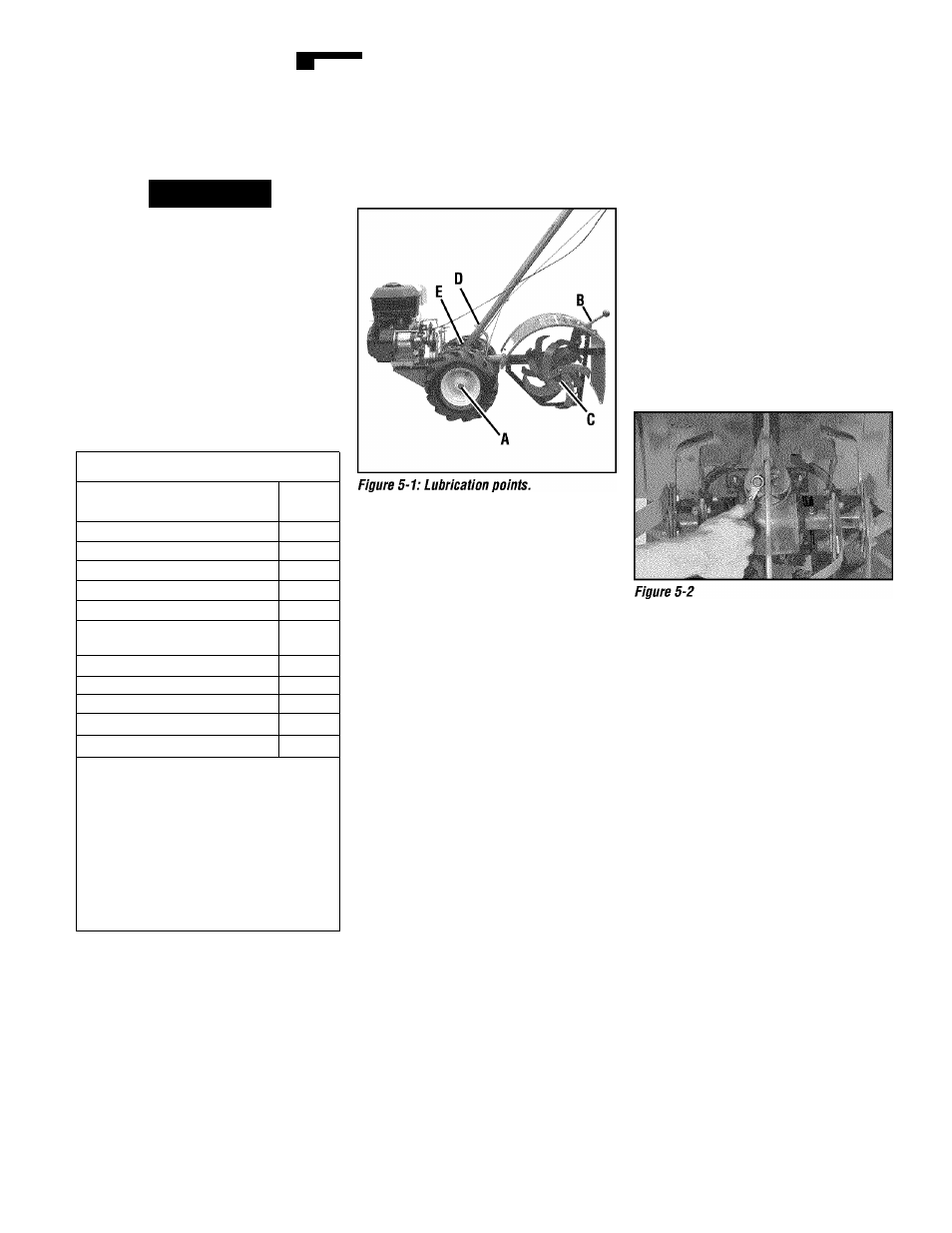

Proper lubrication of the tiller is an essen

tial part of your maintenance program.

After every 10 operating hours, oil or

grease the lubrication points shown in

Figure 5-1 as described below.

Use a good quality lubricating oil (#30

weight engine oil is suitable) and a good

quality general purpose grease (grease

that has a metal lubricant is preferred, if

available).

• Remove wheels, clean wheel shaft (A,

Figure 5-1) and apply thin coating of

grease to shaft.

• Grease back, front and sides of depth

regulator lever (B, Figure 5-1).

• Remove tines, clean tine shafts (C,

Figure 5-1) and inspect for rust, rough

spots or burrs (especially around

holes). File or sand smooth and coat

ends of shaft with grease.

• Oil the threads on the handlebar height

adjustment screw (D, Figure 5-1).

• Oil the threads on the handlebar attach

ing screws (E, Figure 5-1).

CHECK HARDWARE

At least every 10 operating hours, check

the unit for loose or missing hardware

(screws, bolts, nuts, hairpin cotters, etc.).

Loose or missing hardware can lead to

equipment failure, poor performance or

oil leaks.

Be sure to check the three end cap

mounting screws located at the rear of the

transmission (Figure 5-2). Lift the tine

flap to service those screws.

CHECK TIRE PRESSURE

Check the air pressure in both tires.

Deflate or inflate both tires evenly to 15-

to-20 PSI (pounds per square inch). Be

sure that both tires have the same air

pressure or the unit will tend to pull to

one side.