General maintenance – Poulan 210 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

GENERAL MAINTENANCE

A good maintenance program of regular inspection and

care will increase the service life and help to maintain

the safety and performance of your saw.

• Make all adjustments or repairs (except carburetor

adjustment) with:

- spark plug wire disconnected.

- engine cool as opposed to a saw that has just been

• Check the saw for loose bolts, screws, nuts, and fit

tings regularly. Loose fasteners can cause an unsafe

condition as well as damage to your saw.

• Use only POULAN PRO accessories and replace-

ment parts as recommended._________________________

A

WARNING

Have ail chain saw service performed by a qualified ser

vice dealer other than the items listed in the mainte

nance section of this manual.

I

. GUIDE BAR AND CHAIN

Increase the service life of your Guide Bar and Chain by:

- Using the saw properly and as recommended in this

manual.

- Maintaining correct chain tension, page 8.

- Proper lubrication, page 9.

- Regular maintenance as described in this section.

1. CHAIN MAINTENANCE

• Have the chain sharpened by a qualified service

dealer when:

- wood chips are small and powdery. Wood chips

made by tne saw chain should be about the size of

the teeth of the chain.

- saw has to be forced through the cut

- saw cuts to one side.

'

ICAUTION:lAlwavs wear gloves when handling the

chain. The chain can be sharp enough to cut you even

though it is too dull to cut wood.

2. GUIDE BAR MAINTENANCE

• Conditions which can require guide bar n

nance:

- saw cuts to one side.

- saw has to be forced through a cut.

- inadequate supply of oil to bar and chain.

• Check the condition of the guide bar each time

the chain is sharpened. A worn guide bar will

damage the chain and make cutting more difficult.

• Replace the guide bar when:

- the inside groove of guide bar rails is worn.

- the guide bar is bent or cracked. See Figure 31.

• Use only the replacement Reduced-Kickback

a. Remove the guide bar to service.

b. Clean the oil holes at least once after every five

hours of operation.

c. Remove sawdust from the guide bar groove peri

odically with a putty knife or a wire.

Correct

Guide Bar

Groove

M

File-ii

Worn Grooves

File Edges

Square

Figure 31

B. SPARK ARRESTOR

• Carbon deposits build up on the spark arrestor as

the saw is used and must be removed to avoid creating

a fire hazard or causing engine damage.

• Replace the spark arrestor if brealu occur.

• Keep the spark arrestor clean at all times. Clean:

—

as required.

—

at least once for each 25-30 hours of operation.

Items required: wire brush, 8 mm or 5/16" wrench.

1. Disconnect the ^ark plug wire.

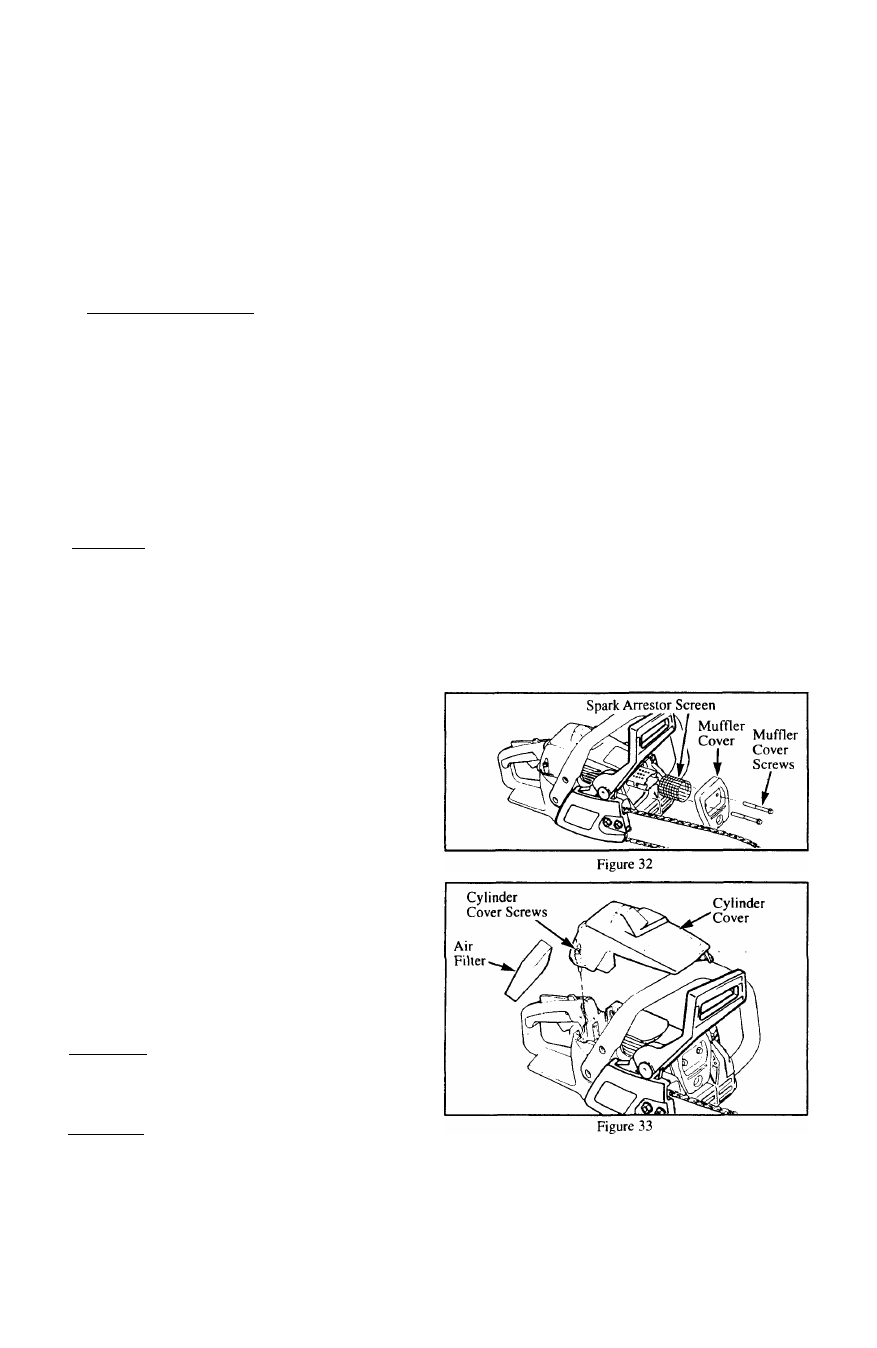

2. Remove the muffler cover screws and muffler cover.

Figure 32.

5. Reassemble parts.

3. Remove the spark arrestor .screen. Figure 32.

'

' ■

' E brush or replace if

C.

AIR FILTER

• A dirty air filter decreases the life and performance

of the engine and may increase fuel consumption and

harmful emissions.

• Clean the air filter as follows:

- check filter after every 20 hours of operation.

- more frequently in very dusty conditions.

1. Remove the cylinder cover screws and cylinder cover.

Figure 33.

2. Pull out the air filter.

3. Wash the filter in soap and water.

[CAUTION:ID

o

not use gasoline or any other flam

mable liquid to clean the filter; doing so can create

1

fire hazard and produce harmful evaporative

emissions.

4.

Reverse steps to reassemble.

[CAUTION:iTo avoid damage to the engine, do not

operate the unit without the air filter in place.