Sharpening or replacing chipper blades, Sharpening or replacing shredding blade – MTD 243-645A000 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SHARPENING OR REPLACING CHIPPER BLADES

1. Disconnect spark plug wire and move it away

from spark plug.

2. Remove the flail screen as instructed in previous

section.

3. Remove the chipper chute by removing three hex

nuts and washers. A 1/2" wrench is required. See

figure 6.

NOTE: When reassembling, the cupped washer goes

on the bottom of the chipper chute with the cupped

side against the chute.

4. Rotate the impeller assembly by hand until you

locate one of the chipper blades in the chipper

chute opening. Remove the blade, using a 3/16"

alien wrench on the outside of the blade and 1/2"

wrench on the impeller assembly (inside the

housing). See figure 7.

Remove the other blade in the same manner.

FIGURE 7.

Replace or sharpen blades. If sharpening, make cer

tain to remove an equal amount from each blade.

Reassemble in reverse order.

Make certain blades are reassembled with the sharp

edge facing the direction shown in figure 10 (sharp

edge is assembled toward the slotted opening in the

impeller assembly).

SHARPENING OR REPLACING SHREDDING BLADE

The shredding blade may be removed for sharpening

or replacement as follows.

1. Disconnect spark plug wire and move it away

from spark plug.

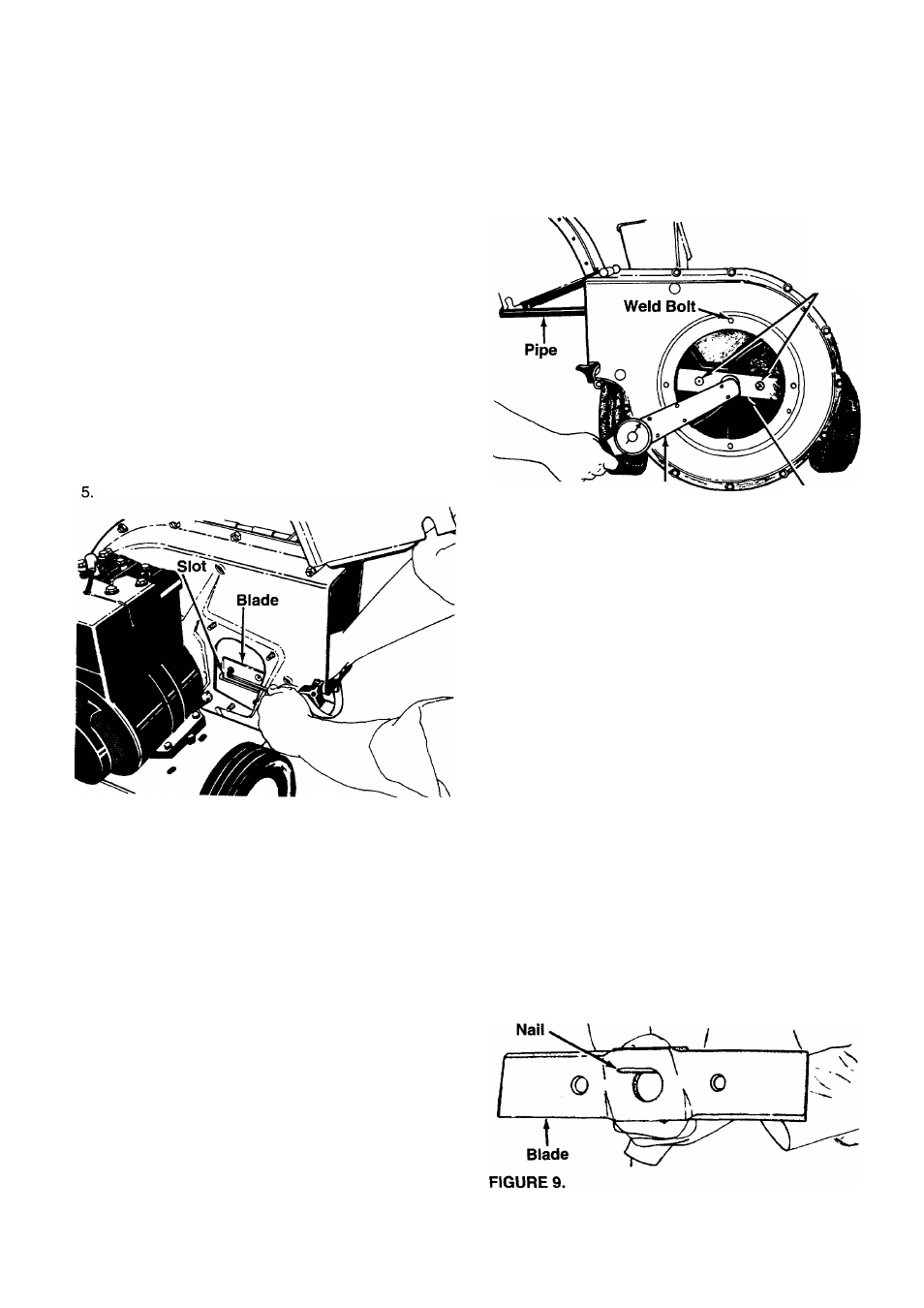

2. Remove the six hex lock nuts and lock washers

from the housing weld bolts using a 1/2" wrench.

Remove the hopper assembly

3. Remove the back-up plate.

NOTE: When reassembling, make certain the open

ing on the back-up piate is toward the bottom of the

unit. The back-up plate may be reversed to provide a

new cutting edge.

Allen

Screws

Torque

Wrench

Blade

FIGURE 8.

4. Loosen the two hand knobs and cupped washers

which secure the chute deflector, and raise the

chute deflector.

5. Keep the impeller assembly from turning by

inserting a 1/2" or 3/4" diameter pipe through the

flail screen, or remove the flail screen, and insert

a piece of wood (2 x 4) into the chute opening.

6. Remove the two outside screws on the blade,

using a 3/16" alien wrench and a 1/2" wrench.

7. Remove the blade by removing the center bolt,

lock washer and flat washer.

NOTE: Use caution when removing the blade to avoid

contacting the weld bolts on the housing.

When sharpening the blade, follow the original angle

of grind as a guide. It is extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. An unbalanced blade

will cause excessive vibration when rotating at high

speeds and may cause damage to the unit.

The blade can be tested for balance by balancing it

on a round shaft screwdriver or nail. Remove metal

from the heavy side until it is balanced evenly. See

figure 9.