A warning, Spark plug, Cooling system – Troy-Bilt 12097 User Manual

Page 12: Tine removal and installation, Arranging tines for narrow tiiiing

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Sections: Maintenance

A

WARNING

* r?

Before inspecting, cieaning or servicing the machine, shut off engine, wait for moving parts to stop, dis

connect spark piug wire and move wire away from spark piug.

Failure to follow these instructions can result in serious personal injury or property damage.

If the engine is running poorly or has low

power while tilling, an adjustment to the

carburetor may solve the problem. How

ever, first inspect and service the spark

plug and the air filter before making a

carburetor adjustment. If the engine con

tinues to run poorly (and the fuel mixture

is fresh), proceed to the following carbu

retor adjustment instructions.This fac

tory-engineered instruction is designed to

provide continued optimum engine oper

ating performance after the engine break-

in period, which is approximately 5 to 10

hours. The adjustment, when properly

performed as described below, will not

void the engine warranty. A common

screwdriver is needed. If you prefer, see

an authorized engine dealer for

adjustment.

Prior to Carburetor Adjustment:

A

WARNING

The temperature of the muffler and adja-

cenf

engine

areas

may

exceed

150°F

(65°C). Contact may cause burns. Avoid

these

areas.

Remove

the

spark

plug

lead and ground the lead to the engine to

prevent accidental starts and fires.

Failure to do this could cause personal

injury.

1. Let engine cool for 30 minutes before

continuing.

2. From the operator’s position behind the

handlebars, lay the machine down on its

left side (muffler side).

Carburetor Adjustment:

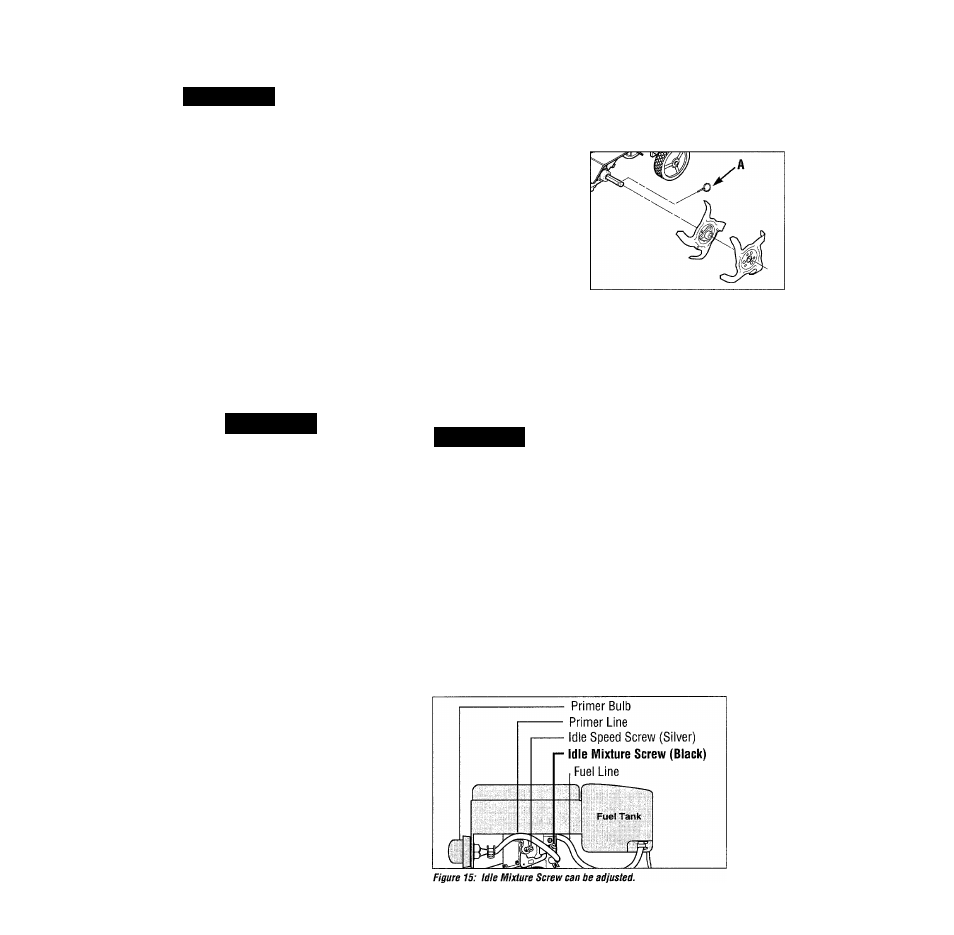

1. Locate the carburetor idle mixture

screw (Figure 15). It is directly under the

air filter and is black.

Do Not Adjust Silver-Colored Screw.

2. Turn the black idle mixture screw 1/16

of a turn clockwise.

3. Return the unit to its normal upright

operating position and reconnect the

spark plug wire.

If the engine continues to run poorly, con

tact an authorized engine dealer.

Spark Plug

Inspect the spark plug annually or every

100 operating hours according to the in

structions in the separate Engine Owner’s

Manual. Check that the gap is set at .030".

For replacement use Champion RCJ-6Y or

equivalent (a resistor spark plug must be

used for replacement).

Cooling System

It is important to frequently check and

remove grass clippings, dirt and other

debris that accumulates on the engine,

cooling fins, air intake screen and on

levers and linkages. This helps to ensure

adequate air cooling and correct engine

speed.

TINE REMOVAL

AND INSTALLATION

A

WARNING

Avoid contact with the cutting edges on

the tines.

To avoid personal injury when removing

or

installing

tines,

wear

heavy

work

gloves.

The

engine

must

be

off,

all

moving

parts

stopped,

and

the

spark

piug wire disconnected from the spark

plug and moved away from the plug.

The tines will wear with use and they

should be replaced if tilling seems to take

longer than usual or if the soil is not

being mixed as thoroughly. Also, in addi

tion to the standard 10" tilling width tine

configuration, the tines can be arranged

in two other configurations: (1) A narrow,

4

V

2

" tilling width for smaller areas and (2)

A special pattern for stony soil conditions.

Figure 16: Remove ring lock pin (A) to take

offlines.

IMPORTANT: The ring lock pin (A, Figure

16) is under spring tension - wear gloves

to protect your fingers when removing or

replacing the ring lock pin.

Arranging Tines for Narrow Tiiiing

1

. Prop the machine forward so it rests

on the front of the tubular carrying

handle. The work surface should be flat

and firm.

2. Flip open the ring (A, Figure 16) on the

left side ring lock pin and remove the ring

lock pin.

3. Remove the outer tine section (do not

remove inner tine section) and mark it as

to which side it is from (left or right) and

whether it’s an outer or inner tine section.

4. Slide one of the long bushings (B,

Figure 17), provided with the unit, onto

the shaft. Insert the ring lock pin through

the rounded side of the tine shaft and

snap the ring down over the shaft (see

DETAIL - Ring Lock Pin, Figure 4, in

Section 2).

5. Repeat this procedure on the opposite

side.

12