Maintenance, A warning, Equipment maintenance – Troy-Bilt 12097 User Manual

Page 11: Transmission maintenance, To check the transmission, To lubricate the transmission, Other lubrication points, Hardware/eiectrical connections, Engine maintenance, Engine lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section

Maintenance

A

WARNING

Before inspecting, cleaning or servicing

the machine, shut off engine, let all

moving parts come to a complete stop,

disconnect the spark plug wire and move

the wire away from the spark plug.

Failure to follow these instructions can

result

in

personal

injury

or

property

damage.

EQUIPMENT MAINTENANCE

Transmission Maintenance

The transmission was lubricated at the

factory and should not require any further

lubrication.

However, you should check the lubricant

level after the first five (5) hours of opera

tion and every twenty-five (25) operating

hours thereafter. If needed, use a high-

quality, automotive-grade petroleum-base

grease.

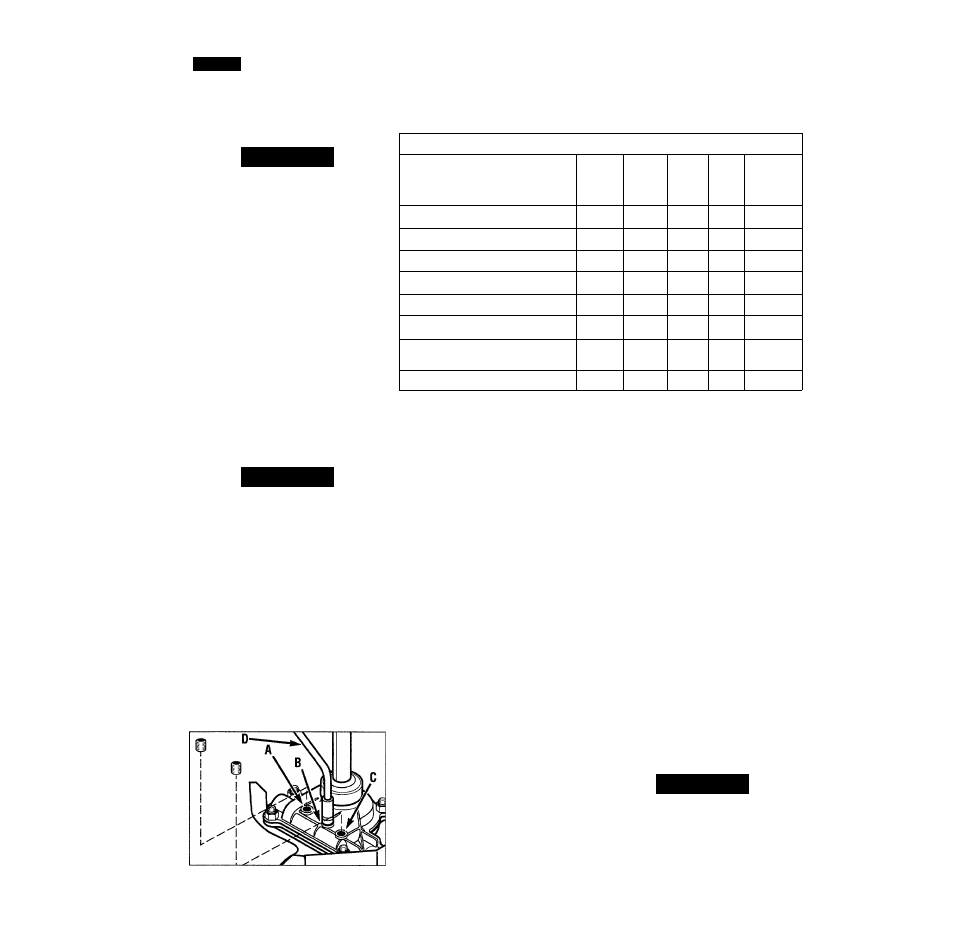

REQUIRED MAINTENANCE SCHEDULE

REQUIRED MAINTENANCE

Before

After

Every

Every

End

Each

Each

25

75

of

Use

Use

Hours

Hours

Season

Check Tightness of Bolts and Nuts

•

Clean Engine Cooling System

•

Check Transmission Lubricant

.(1)

•

Service Air Filter

.(2)

Inspect Spark Plug

• (3)

Clean Machine

•

Clean Engine Exhaust Ports

•

(see Factory or authorized Dealer)

Clean Tine Shaft

•

id) - After first five (5) hours of use.

i (2) - Clean daily when conditions are

i

extremely dusty or dirty.

i(3) - Check spark plug annually or every 100

[

operating hours.

A

WARNING

Before tipping engine or equipment to

service

transmission,

drain

fuel

from

tank by running engine until fuel tank is

empty.

To check the transmission:

1. Stop the engine, let It cool and discon

nect the spark plug wire.

2. Place the machine down on its left side

so the right end of the tine shaft faces up.

3. Remove the right-side tines (see Tine

Removal and Installation in this Section).

4. Clean the transmission housing.

5. Remove the three threaded plugs (A, B

and C, Figure 14) from the transmission.

Lubricant should be visible In the top two

Figure 14: Transmission lubricant check and

fill locations.

holes (B and C). If so, replace all three

plugs. If lubricant is needed, proceed as

follows.

To lubricate the transmission:

1. Place the nozzle of a standard grease

gun (D, Figure 14) firmly against the rim

of the middle hole (B) and add grease

until it begins to seep from the bottom

hole (A). Reinstall the plug in the bottom

hole (A). Next apply grease to the top fill

hole (C) until it begins to seep from the

middle hole (B). Reinstall the plugs in the

middle (B) and top (C) holes.

2. Before reinstalling the tines, use a fine

grade sandpaper to clean any rust off the

tine shaft. Apply a few drops of oil to the

tine shaft to make future tine removal

easier.

Other Lubrication Points

• Handlebar Adjustment Knobs; Spray

occasionally with a silicone type

lubricant.

• Throttle/Tines Lever Cable: Squeeze the

lever closed and spray a lubricant into

the cable area.

• Tine Shaft: After each use, remove the

tines, clean the tine shaft with sandpaper

and apply a light coat of oil to the tine

shaft.

Hardware/Eiectrical Connections

Before each use, check that ail hardware

is tight and that the On/Off Switch wire

connections are secure. Also check that

the switch wiring is in good condition.

ENGINE MAINTENANCE

Engine Lubrication

The engine is a two-cycle engine. Lubri

cation is provided by mixing two-cycle oil

with unleaded regular gasoline as de

scribed in the AssemWy Section. At

tempting to operate the engine on gaso

line alone will cause the engine to over

heat and seize up.

Engine Air Fiiter

It is extremely important that air filter ser

vice be performed according to the main

tenance schedule. Refer to the separate

Engine Owner’s Manual for inspection and

cleaning instructions.

IMPORTANT: Never run engine without air

filter assembly properly installed on engine.

Carburetor Adjustment

A

WARNING

Do not tamper with the engine governor

screw which is factory-set for the proper

engine speed. Overspeeding the engine

beyond the factory high speed setting

can

be

dangerous

and

wiii

void

the

engine

warranty.

Authorized

service

shail be sought if a probiem exists.

11