Note, B. oil change, Chain case lubrication – MTD 215-395A User Manual

Page 8: Chain adjustment, Air filter

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

NOTE

This tiller is equipped with a variable

speed pulley making it necessary for

the engine to be running to move

the control lever into the faster speeds.

A downward pressure on the handles

will increase working depth and re

duce the forward speed. An upward

pressure on the handles will reduce the

working depth and increase the for

ward speed. The type of soil and work

ing conditions will determine the actual

setting of the depth bar and the handle

pressure required.

If the tines stop rotating or the belt

slips, stop the engine and examine the

tine area for a rock or some object that

may be jamming the tines and prevent

them from turning. Reversing the tiller

will usually free the object.

NOTE

If the tines tend to bounce instead of

cutting into the soil, one or more sets

of tines may be on backwards. The

cutting edge of the tines should enter

the soil first.

Step 6. To reverse the direction of rotation of the

tines, pull the control lever into the reverse

position. The control lever must be held in

reverse. See figure 9.

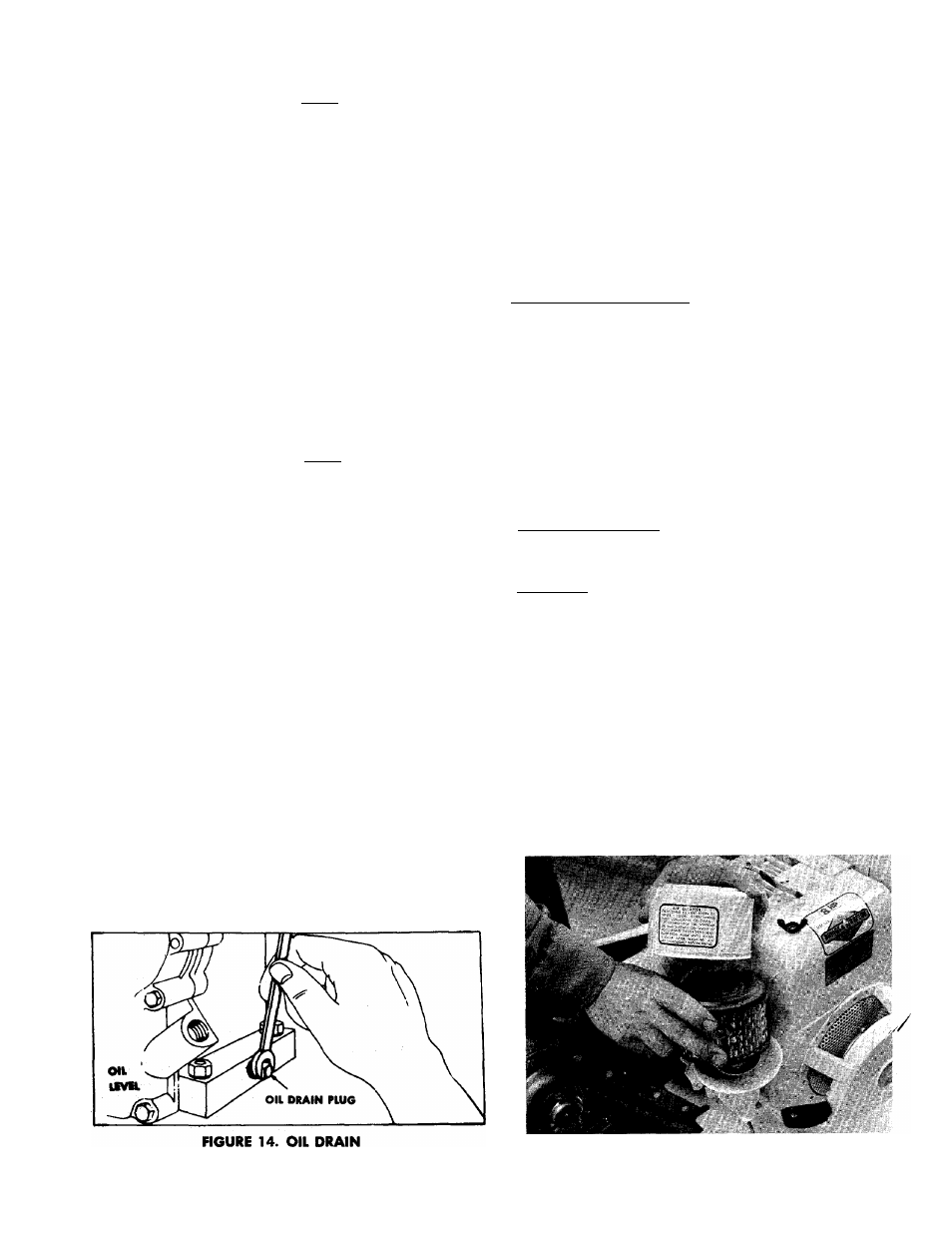

b. Oil Change

To avoid spilling gasoline on your lawn or driveway,

plan to change the oil when the gasoline tank and car

buretor are empty.

After the first two hours of operating a new engine,

drain the oil from the crankcase while the engine is

still hot and refill the crankcase with new oil; there

after change the oil after every 25 hours of operation.

This procedure ensures for minimum wear of engine

parts and provides for virtually trouble-free operation.

To change the oil, proceed as follows:

Step 1. With the machine on level ground, place a

suitable metal container under the oil drain

plug, then remove the drain plug. See figure

12.

Step 2. After the oil has been drained completely

from the crankcase, replace the drain plug and

tighten.

Step 3. With the tiller on level ground, remove the

oil filler plug (See figure 16). Fill the crankcase

until the oil overflows from the oil fill hole.

Fill slowly to avoid air locks. The crankcase

should hold approximately 2% pints of SAÉ

30 type MS engine oil. Replace the oil filler

plug.

CHAIN CASE LUBRICATION

The chain is permanently lubricated and requires no

further lubrication unless the case is disassembled for

repair.

If the case is disassembled, clean the chain with kero

sene, allow it to dry and work a high temperature

grease, such as Lubriplate No. 310 into the chain.

NOTE

A 4 oz. container of Lubriplate No. 310

is available under part number 727-0136.

CHAIN ADJUSTMENT

No chain adjustment is necessary.

AIR FILTER

Under normal operating conditions, the air cleaner,

located on top of the carburetor, must be serviced

after every ten hours of use. Under extremely dusty

operating conditions, the air cleaner must be serviced

after every hour of operation. See figure 15.

Step 1. Remove the wing nut and cover.

Step 2. Remove the paper element from the support

base.

Step 3. To clean, tap the paper element (either top or

bottom) on a flat surface or wash in a non-

sudsing detergent and flush from the inside

until the water is clear. After washing, air dry

thoroughly before using.

FIGURE 15. AIR CLEANER