Carburetor / governor adjustment, Throttle control adjustment, Wheel gear cable adjustment – Troy-Bilt REAR-TINE TILLER 675B User Manual

Page 18: Off season storage, Tines, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A

WARNING:

Before inspecting, cleaning or servicing the machine, shut off engine, wait for ail

moving parts to come to a complete stop, disconnect spark plug wire and move wire away from

spark plug. Failure to follow these instructions can result in serious personal injury or property

damage.

Carburetor / Governor Adjustment

A

WARNING:

Operators

shall nottamperwith theengine

governor settings; the governor

controls the maximum safe

operating speed to protect the

engine and all moving parts

from damage caused by

overspeed. Authorized service

shall be sought If a problem

exists.

The carburetor was adjusted at the factory

for best operating speed. Refer to the sep

arate Engine Owner’s Manual for any ad

justment information or see your

authorized engine service dealer.

The governor controls the maximum safe

operating speed and protects the engine

and all moving parts from damage caused

by overspeeding. Do not tamper with the

engine governor settings. Seek authorized

service if a problem exists.

Throttle Control Adjustment

If the engine does not respond to various

throttle lever settings, refer to the separate

Engine Owner’s Manual for service infor

mation or contact your local authorized en

gine service dealer.

Wheel Gear Cable Adjustment

When the Wheel Gear Lever is in DISEN

GAGE. the wheels will roll freely (free

wheel). The wheels should not roll freely

when the lever is in ENGAGE. If the wheels

roll freely when the Wheel Gear Lever is in

ENGAGE, the wheel gear cable needs to be

adjusted as described below.

1. With the engine shut off and the spark

plug wire disconnected, put the Wheel

Gear Lever in ENGAGE.

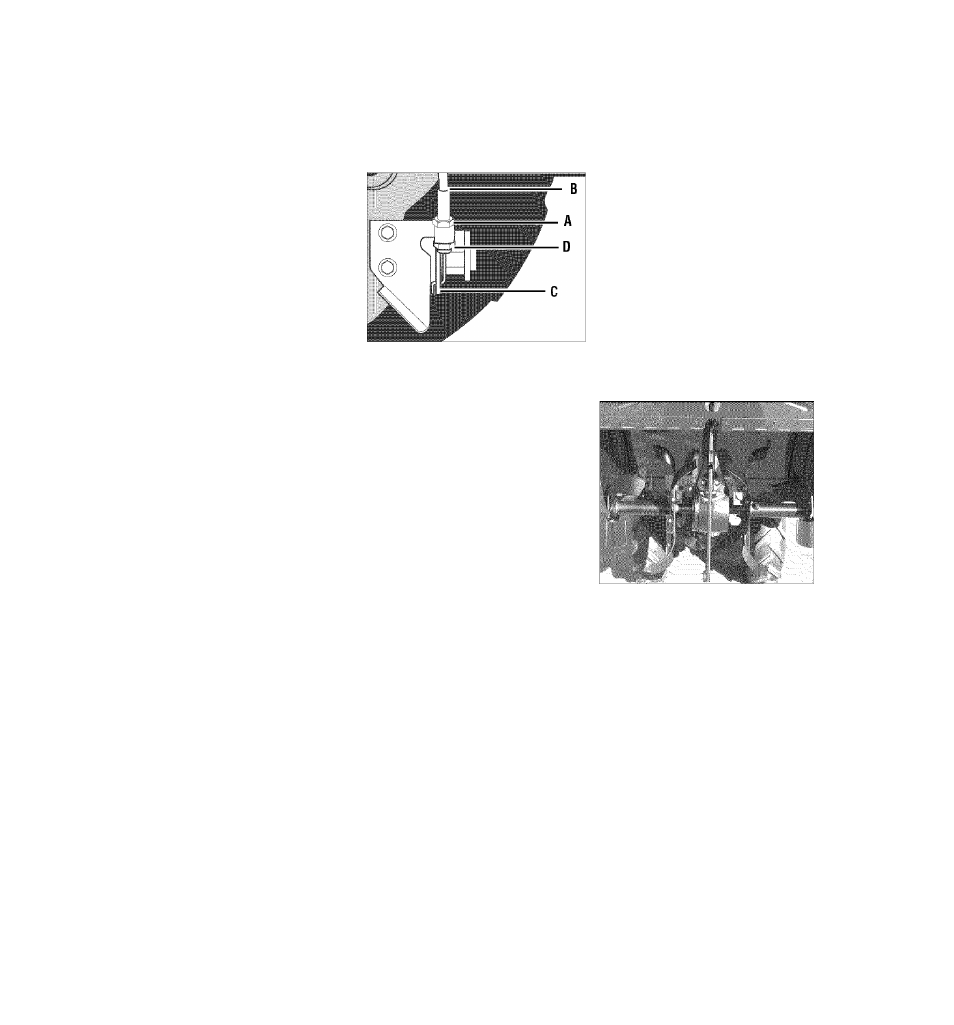

2. Loosen the top adjustment nut

the wheel gear cable bracket located on the

left side rear of the transmission.

3.

Push wheel gear cable (B) down and roll

tiller slightly forward or backward until ec

centric lever (C) engages (locks) wheels.

Hold cable in that position and tighten top

(A) and bottom (D) adjustment nuts.

Figure 5-5: Wheel gear cable assembly.

4.

Move Wheel Gear Lever to ENGAGE and

DISENGAGE several times to check adjust

ment. The wheels should not roll when the

lever is in ENGAGE, but they should roll

when the lever is in DISENGAGE. Readjust

the cable as required.

Off Season Storage

When the tiller won’t be used for extended

periods, prepare it for storage as follows:

1. Clean the tiller and engine.

2.

Do routine tiller lubrication (see Tiller

Lubrication) and check for loose parts and

hardware (see Check Hardware).

3.

Protect the engine by performing the

engine storage instructions in the separate

Engine Owner’s Manual.

NOTE: Be sure to protect the fuel lines, car

buretor and fuel tank from gum deposits

by removing fuel or by treating fuel with a

fuel stabilizer (follow engine manufactur

er’s recommendations).

4.

Store unit in a clean, dry area.

5.

Never store the tiller with fuel in the fuel

tank in an enclosed area where gas fumes

could reach an open flame or spark, or

where ignition sources are present (space

heaters, hot water heaters, furnaces, etc.).

Tines

The tines will wear with use and should be

inspected at the beginning of each tilling

season and after every 30 operating hours.

Tines can be replaced individually or as a

complete set. Never inspect or service the

tines unless the engine is stopped and the

spark plug wire is disconnected.

18

NOTE:

The

tiller

hood

must

be

removed to take off either a single tine

holder or individual tines. The hood is

secured to the transmission housing

with two rear bolts and two front bolts.

Tine Inspection

With use, the tines (Figure 5-6) will be

come shorter, narrower and pointed. Badly

worn tines will result in a loss of tilling

depth and reduced effectiveness when

chopping up and turning under organic

matter.

Removing and Instaliing

Figure 5-6: Four tine gangs: two per side.

1. Use a 9/16" socket, 6" extension, a

ratchet, and a 9/16" box wrench to loosen

the nut (A, Figure 5-7) and bolt (B) that se

cure the tine holder to the tine shaft.

2.

Use a rubber mallet to tap the tine hold

er loose.

3.

Slide the tine assembly off the tine shaft.

4.

Repeat Steps 1-through-3 above to re

move the other tine assembly.

5.

Installing the tine assembly is simply

the reverse of its removal. Be sure the cut

ting edges face so they will enter the soil

fi rst when the tiller is moving forward-

this

means the cutting edges face toward the

operator position.

First be sure to remove any rust, uneven

spots or burrs from the tine shaft, using

fine sandpaper. Then grease the tine shaft

before reinstalling the tine assemblies.

Tighten the hardware very securely.