Maintenance, Lubrication, Engine – MTD 645C thru 650C User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

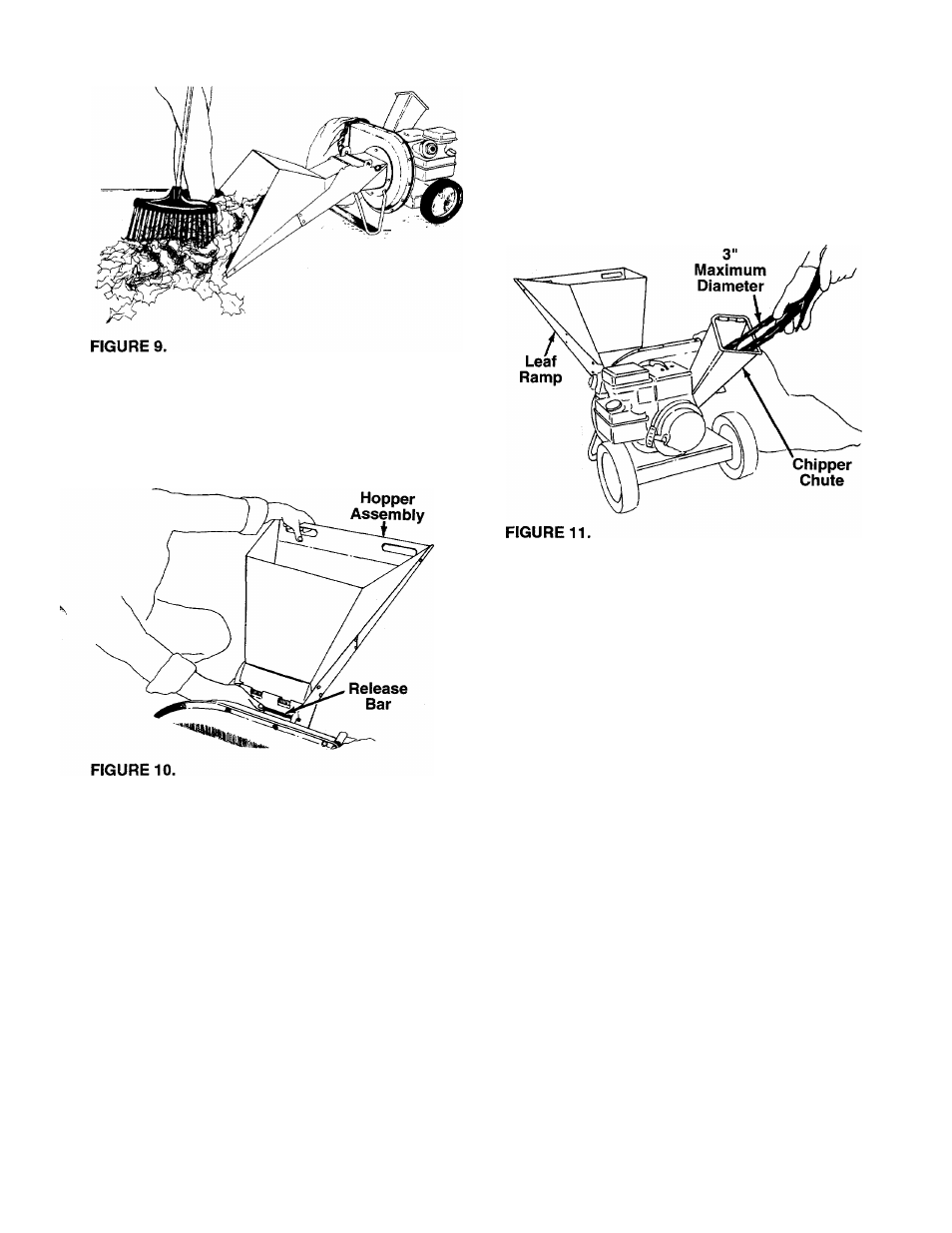

To lower the hopper assembly, use one hand to

grasp the handle at the top of the hopper assem

bly and lift slightly. Pull up on the release bar, and

lower the hopper assembly to the ground.

Release the bar. See figure 10.

3. Bulky material, such as stalks or heavy branches,

up to 3" in diameter

should be fed into the chip

per chute. See figure 11.

A

WARNING: Make certain the chipper

chute door is closed when not in use.

IMPORTANT:

There is a flail screen located inside

the housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

the Maintenance section on page 8.

For best performance, it is important to keep the

shredding blade and the chipper blades sharp. Refer

to Maintenance section, pages 8 and 9. If the compo

sition of the material being discharged changes

(becomes stringy, etc.) or if the rate at which the

material is discharged slows down considerably, it is

likely that the shredding blade and/or chipper blades

are dull and need to be sharpened or replaced.

MAINTENANCE

A

WARNING: Always stop engine and dis

connect spark plug wire before cleaning,

lubricating or performing any repairs or

maintenance.

LUBRICATION

Lubricate the pivot points on the release bar, guide

extension assembly, chute deflector and chipper

chute once a season using a light oil.

ENGINE

Refer to the separate engine manual for engine main

tenance instructions.

Maintain

engine oil

as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service

air cleaner

every 25 hours under normal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The

spark plug

should be cleaned and the gap reset

once a season. Spark plug replacement is recom