Chipper blade removal/instalution, A warning, Chipper blade removal/lnstallation – Troy-Bilt 47330 User Manual

Page 20: Cylinder assembly components, Warning, Chipper blade removal/instalution a

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

20 Section 5: Maintenance

'A

A

WARNING

Faiiure to foiiow these instructions can result in serious personal injury or property damage.

Before inspecting, cieaning or servicing the machine, shut off engine, wait for aii moving parts to

come to a compiate stop, disconnect spark piug wire and move wire away from spark piug.

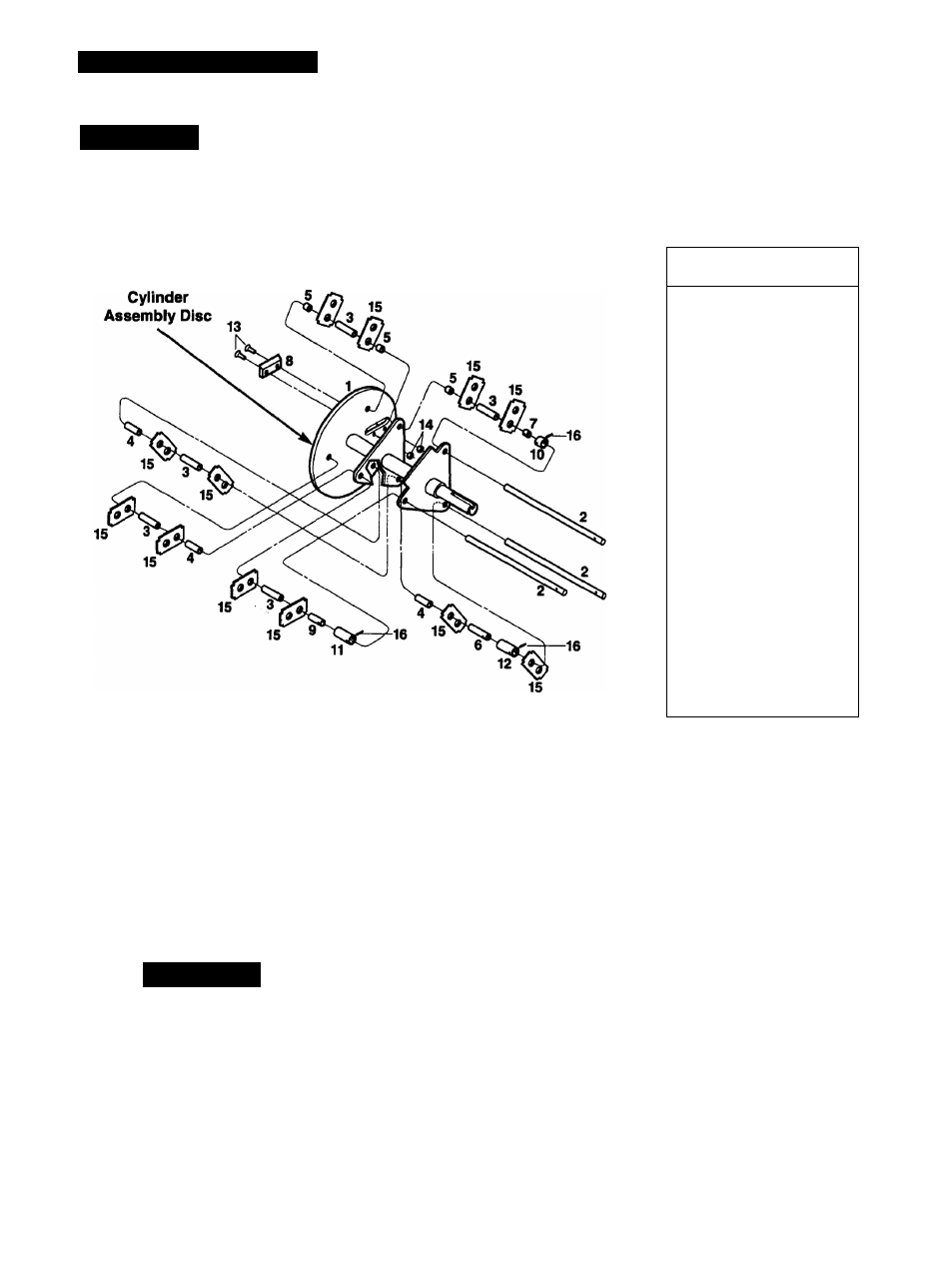

CYLINDER ASSEMBLY COMPONENTS

15

Figure 5-5A

Ref.

No.

Description

1

Cylinder Weldment

2

Pin, Cylinder

3

Spacer, Long, 2'

4

Spacer, Medium, 1-5/16“

5

Spacer, Short, 11/16“

6

Spacer, Long, locking, 2“

7

Spacer, Short, locking,

11/16"

8

Blade, Chipper

9

Spacer, Medium, locking,

1-5/16“

10

Sleeve, Short, outer, 1/2“

11

Sleeve, Medium outer,

1-1/8“

12

Sleeve, Long, outer,

1-3/4“

13

Screw, FI. Csk. Socket Hd.,

1/4“-20x1“

14

Nut, Hex Locking, 1/4“-20

15

Blade, Shredder

16

Pin, Roll, 3/16“

X

3/4“

7. Reinstall the hopper assembly using the

eight flange screws removed in Step 2 of

Cylinder Assembly Removal.

8. Reinstall the upper section of the clutch

lever using the two screws and nuts

removed in Step 1 of

Cylinder Assembly

Removal.

CHIPPER BLADE

REMOVAL/INSTALUTION

A

WARNING

The chipper blade is extremely sharp.

To avoid personal injury, handle the

blade with extreme care during service

or maintenance.

Shut engine off, let all moving parts

stop completely, disconnect spark piug

wire and prevent it from touching spark

plug before performing any mainte

nance on the unit.

The chipper blade should be sharpened or

replaced when the unit no longer cuts as

efficiently as when new.

"Chipper Blade Removal

1. Stop engine and wait for all parts to

come to a complete stop. Disconnect

spark plug wire and secure it away from

spark plug.

2. Lower the front end of the discharge

screen (or remove screen for more work

ing room). Refer to

Removing/lnstalling

Discharge Screen or Bar Grate

in Section

4 for instructions.

3. Remove and save the three flange

screws (A, Figure 5-6) from the base of

the chipper chute and remove the chute.

4. The chipper blade Is extremely sharp

- wear heavy leather gloves when work

ing near it.

5. Wearing gloves, rotate the large round

flywheel carefully until the chipper blade is

exposed in the chipper chute opening.

6. Prevent the flywheel from turning by

wedging the cylinder assembly against the

internal walls of the machine with a sturdy

block of wood.

7. Using a 5/32" hex key wrench and a

7/16“ open-end wrench, reach up inside

the shredder chamber and remove the two

nuts and socket head screws from the

chipper blade (see Figure 5-7). Remove

the chipper blade.

8. If a blade is dull or nicked, sharpen it at

a 45“ angle. See inset. Figure 5-7. If you

don’t have sharpening experience and the

proper equipment, take the blade to a pro

fessional sharpening service.

If the blade is cracked or damaged,

throw it awayl Never use a cracked

blade since pieces of the blade could

break off and cause personal injury.