A warning, Equipment maintenance, Lubrication – Troy-Bilt 47330 User Manual

Page 17: Drive belt service, Belt inspection, Belt installation, 51 maintenance, Il maintenaiice schedule

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section

51 Maintenance

A

WARNING

Moving parts on the unit can cause seri

ous personai injury.

Shut off the engine, iet aii moving parts

stop completeiy, disconnect the spark

piug wire and prevent it from touching

the spark piug before performing any

maintenance or service procedures.

il Maintenaiice

Schedule

Before

Each

Use

Every 25

Hrs. of

Operation

Annually

At End

of

Season

Prior to

storing

Comments

Check engine oil level

/

Every 8 hrs.

Check hardware for tightness

✓

✓

Check that engine is free

of flammable debris

/

/

(4)

Change engine oil

✓

(1)

/

(4)

Service engine air cleaner

/(2)

(4)

Replace spark plug

(4)

Clean unit

✓

✓

✓

Inspect engine spark

arrester

(3)(4)

Check belt condition.

/

Clean engine cooling system

/(5)

(4)

Clean engine fuel filter

(3)(4)

(1) Change after the first 5 hours of operation.

(2) Service more often under dusty conditions or when airborne debris is present.

(3) Every 50 hours of operation if engine is equipped with this item.

(4)

See Engine Owner’s Manual for instructions.

(5) Every 100 hours or every season.

EQUIPMENT MAINTENANCE

Follow the Maintenance Schedule above to

keep your equipment properly maintained.

See the separate Engine Owner’s Manual

for specific engine maintenance informa

tion and instructions.

LUBRICATION

There are no parts or assemblies on the

unit (other than the engine) that require

periodic lubrication.

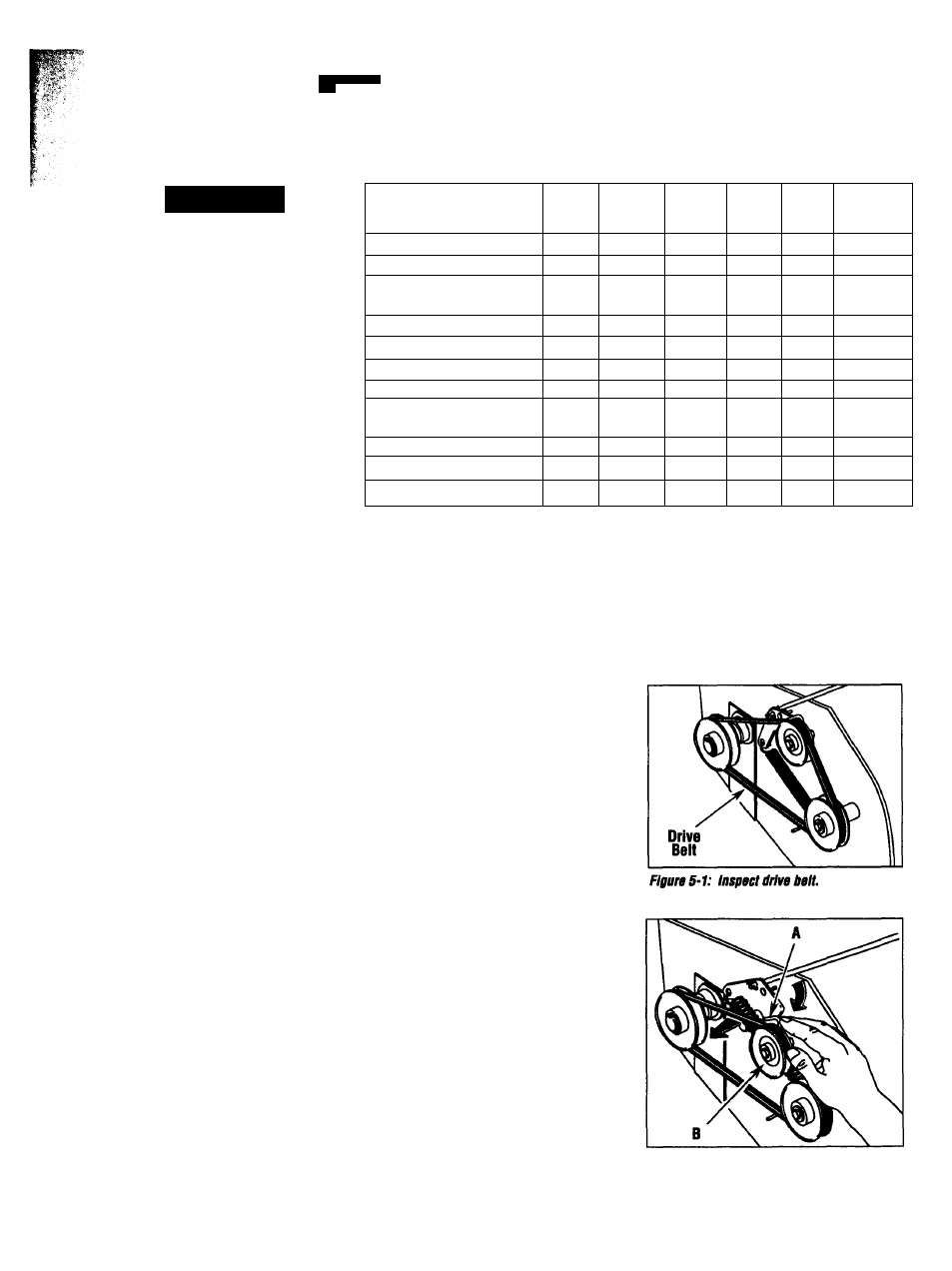

DRIVE BELT SERVICE

After every 25 operating hours, examine

the drive belt for cuts, cracks, fraying or

other damage. See Figure 5-1. Examine

the clutch lever operation to see that it

moves the idler pulley property. The idler

pulley is spring-loaded and maintains ten

sion on the belt until the clutch lever is

squeezed to take tension off the belt for

easier engine starting.

BELT INSPECTION

1. Stop engine and wait for all parts to

come to a complete stop. Disconnect

spark plug wire and secure it away from

spark plug.

2. Remove the four screws securing the

belt cover. Remove the belt cover.

3. Replace the belt if it is worn or dam

aged (refer to

Belt Removal/lnstallation

below). Replace belt cover and reconnect

spark plug wire.

BELT REMOVAL/INSTALLATION

Belt Removal

1. Stop engine and wait for ali parts to

come to a complete stop. Disconnect

spark piug wire and secure it away from

spark plug.

2. Remove the four screws securing the

belt cover. Remove the belt cover.

3. Loosen (do not remove) nut securing

wire belt guide (A, Figure 5-2). Move belt

guide away from idler pulley (B).

4. Push idler pulley (B, Figure 5-2) down

ward and remove belt from pulleys.

Belt Installation

1. Place the belt in the grooves of the two

main pulleys.

2. Push idler pulley (B, Figure 5-2) down

and route belt into groove of idler pulley.

3. Position the wire belt guide 1/16"-1/8“

away from the belt. Tighten the nut to

secure the belt guide in place.

4. Reinstall belt cover and reconnect

spark plug wire.

Figure 5-2: To remove belt, loosen belt

guide (A) and push Idler pulley (B) down.