Cylinder assembly service and repair, A warning, Cylinder assembly removal – Troy-Bilt 47330 User Manual

Page 18: Cylinder assembly disassembly, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

18 Section 5: Maintenance

A

WARNING

Faiture to foitow these instructions can resutt in serious personat injury or property damage.

Before inspecting, cieaning or servicing the machine, shut off engine, wait for ait moving parts to

come to a comptete stop, disconnect spark ptug wire and move wire away from spark ptug.

CYLINDER ASSEMBLY

SERVICE AND REPAIR

A

WARNING

Before performing any maintenance on

the unit, stop the engine, wait for ait

moving parts to stop and disconnect

spark ptug wire. Wear gioves when

working with the cyiinder assembty to

protect against cuts.

Cylinder Assembly Removal

1. Remove the upper clutch lever section

from the lower section by removing the

two screws and nuts.

2. Remove the eight flange screws secur

ing the shredder hopper to the unit.

Remove the hopper.

3. Remove the discharge screen or bar

grate (see

Removing/lnstalling Discharge

Screen or Bar Grate

in Section 4).

Remove the belt cover as described in

Belt Removal/lnstallation

in this Section.

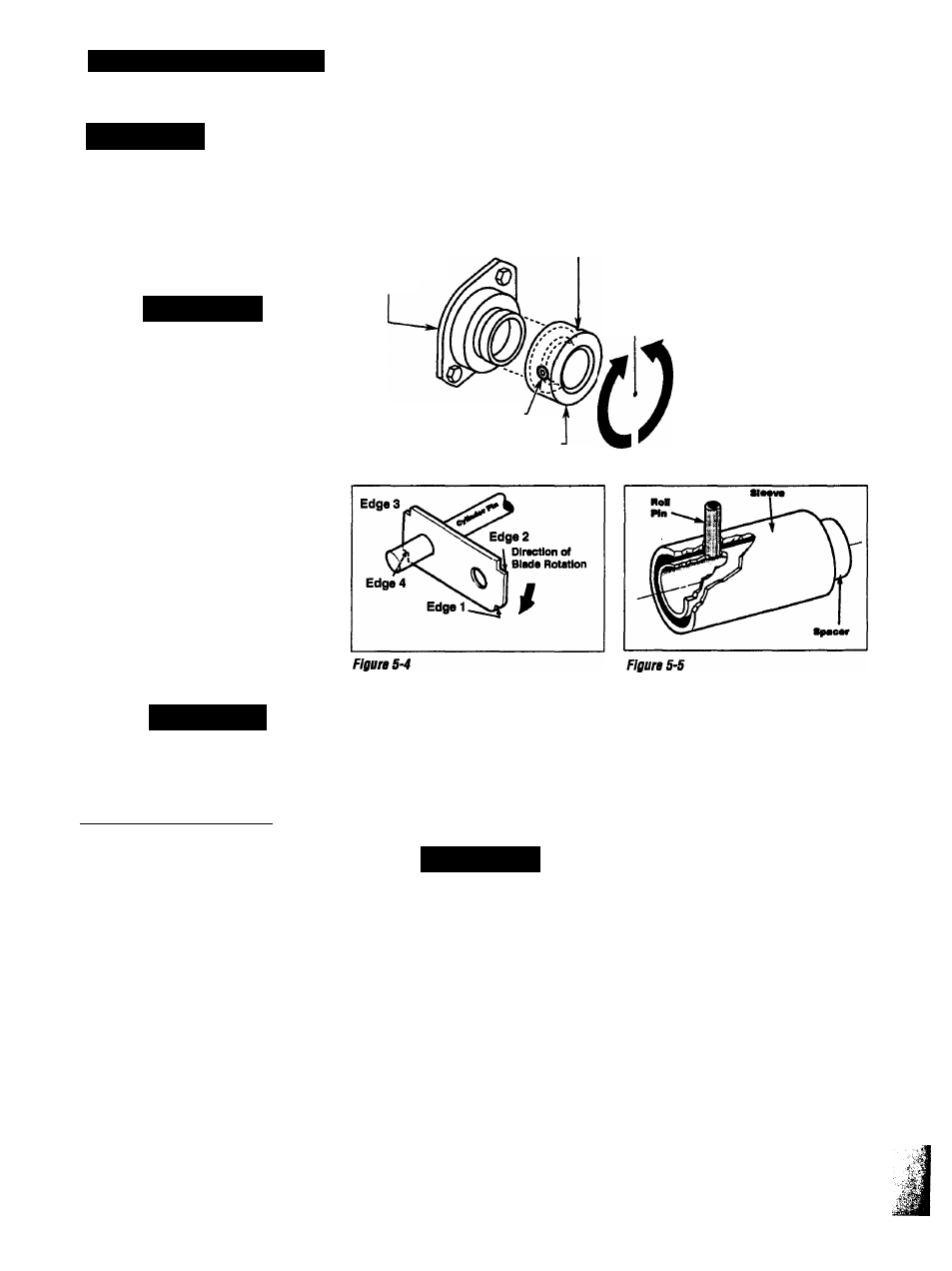

HOLE FOR PUNCH

BEARING

• Tighten In direction of

shott rotetlon (counter

clockwise)

• Loosen egelnst direc

tion of shaft rotation

(clockwise)

SET SCREW-

Figure 5-3

BEARING COLLAR

A

WARNING

Wear sturdy work gioves and bo careful

handling the cylinder assembly. Many

cutting edges on the assembly can

cause severe cuts. Be especially care-

tul near the chipper blade.______

4.

Remove the snap ring that secures the

cylinder pulley to the cylinder assembly.

Carefully note (for later reassembly) the

location of all hardware securing cylinder

pulley to cylinder. Remove the cylinder

pulley.

5. Loosen set screw that secures bearing

locking collar on cylinder shaft (located

under cylinder pulley). Remove the lock

ing collar from the cylinder shaft by turn

ing the collar against the direction of the

shaft rotation. Use a hammer and a punch

to loosen the collar (Figure 5-3).

6. Place a long wooden stick down the

shredder hopper to prevent the cylinder

assembly from rotating. Remove the cap

screw securing the other end of the cylin

der shaft. Remove the remaining washers

and spacers from the cylinder shaft. Note

that there is a felt washer at each end of

the shaft to protect the bearings. Also

note the location of all hardware for

reassembly. Remove the stick from the

.Jiopper.

A

WARNING

Take special care to note the exact or

der and placement of all parts on the

cylinder assembly for reassembly. It is

recommended that the cyiinder pins and

all components be marked before disas

sembly to aid In correct reassembly. If

there are any questions about correct

placement and order of cylinder assem

bly parts, refer to the cylinder assembly

parts breakdown (located in the parts

list). Failure to follow these instruc

tions could result in severe personal

injury or property damage.

NOTE; An assistant will be needed for the

next step.

7. Put on sturdy work gloves and safety

glasses. Hold the cylinder assembly

through the hopper opening. Remove the

six flange screws (keep any washers with

screws) retaining the cylinder shaft bear

ings and the closure plate to the main

frame. The cylinder assembly can now be

lowered out of the unit.

The shredder blades (flails) on the cylinder

assembly can be rotated or flipped if dull

(Figure 5-4). The shredder blades use

only one cutting edge at a time.

Cylinder Assembly Disassembly

NOTE; Roll pins (see Figures 5-5 and

5-5A) secure the three cylinder pins in the

cylinder assembly. The roll pins must be

driven from the assembly with a 5/32*

punch and hammer. The pins will come

out in only one direction through the outer

sleeves (Figure 5-5).

1. Securely clamp the cylinder assembly

by the chipper flywheel in a vise. Position