Ariens SNO- THROS 932007 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CHUTE CRANK ADJUSTMENT

REPLACEMENT OF THE BLOWER DRIVE BELT

In the event the chute crank fails to rotate freely, loosen the

nut securing the worm clevis to the bracket. This hole in the

bracket is slotted to permit adjustment. Position the worm

so there is a little clearance between worm and the gear

teeth on the blower. Tighten the nut. Rotate the discharge

chute through its full travel to see that it turns easily. Re

adjust if required. Lubricate as described under LUBRI

CATION for smooth operation.

BELT REPLACEMENT

CAUTION:

SINCE REPLACING THE BEL TS WILL INVOL VE TURNING

THE ENGINE OVER WITH THE STARTER, THE SPARK

PLUG WIRE MUST BE DISCONNECTED DURING THIS

PROCEDURE.

The drive belt and the attachment drive belt are both ac

cessible by tipping apart the blower housing and tractor as

follows:

1. Remove the nut and lockwashers holding the worm clevis on

the bracket. Remove the chute crank by sliding it back in

the bracket and out of the way.

2. Remove the two flanged whiziock screws securing the belt

guard to the tractor. Remove the belt guard.

3. Remove the top cap screws and loosen the lower cap screws

on each side that secures the blower housing to the frame.

As the blower housing and tractor are tipped apart, roll

finger. This can be easily done by pulling the recoil

starter rope to rotate the engine sheave. With the belt dis

connected, the blower housing may then be tipped from

the frame.

TRACTION IDLER

y'

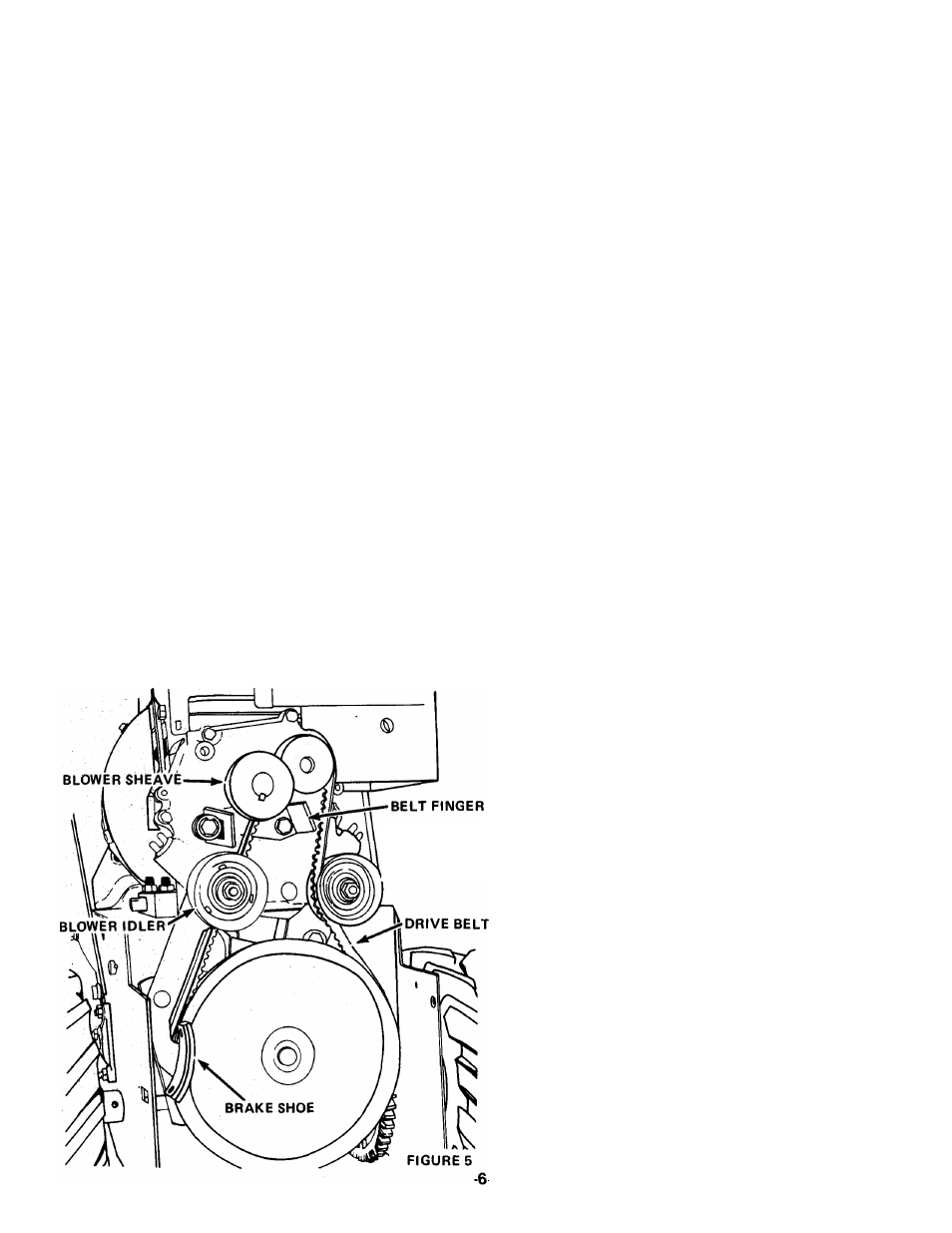

The blower drive belt remains on the sheave on the blower

housing. Place the new belt on the sheave. Hold it in position

on the sheave as the blower is tipped into position on the^^^^

tractor. Be sure the brake shoe seats on the belt as the units,

1'

are tipped together. Once assembled, roll the blower belt on to

the engine sheave and position the idler on the outside of

the belt.

REPLACEMENT OF TRACTION DRIVE BELT

With the blower and tractor tipped apart, pull the idler

away from the drive belt and remove belt from around

the lower sheave and engine sheave. Install the new belt on

the engine sheave and lower sheave. Then reposition the

idler back into position on the outside of the drive belt.

With the belts in position and the idler in place, check the

belt alignment. The engine sheave and the tractor sheave

must align with one another. If the sheaves are not properly

aligned, loosen the setscrews on the engine sheave and align

the sheaves. Retighten the setscrews.

REPLACEMENT OF BLOWER HOUSING

1. Tip the blower and tractor together. Hold the blower drive

belt up as the units are tipped together. Be sure the blower

brake shoe seats on the blower sheave. Secure with the two

cap screws into the frame.

2.

Roll the blower belt on to the engine sheave. Pull the

recoil starter rope to turn the engine sheave and roll the

belt into place under the belt finger.

3.

Check the belt finger spacing. There should be 1/8 inch

clearance between the belt finger and belt with the blower

clutch engaged. Readjust the belt finger if required.

4. Check the sheave alignment with the blower belt in place.

Readjust as required to align the sheaves. It may be neces

sary to tip the blower housing away from the tractor to

gain access to the blower sheave.

5. Replace the belt guard and chute crank assemblies. Re

adjust the chute crank as described in the paragraph above.

Replace the spark plug wire.

REPLACEMENT OF FRICTION WHEEL

1.

Tip the machine up on the blower housing and brace

securely. Remove two cap screws at back of frame securing

the bottom cover and loosen two cap screws at front

frame sides and remove the cover.

2. Remove the four whiziock nuts holding the bearing flange

on the right hand side of the frame. Remove the bearing

flange and carriage bolts.

3.

Remove the hairpin cotter from the traction clutch rod.

Pull this rod from the clutch fork arm and tip it up and out

of the way.

4. Slide the friction wheel assembly and hex shaft to the right

until the left end of the hex shaft comes free of the left

bearing. Then slip the whole assembly back to the left and

pull it forward out of the frame.