Dealer set up and pre-service – Ariens SNO- THROS 932007 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

DEALER SET UP AND PRE-SERVICE

1. GENERAL

The unit is shipped with tractor and snow head assembled.

The handlebars are assembled but must be installed on the

tractor and the clutch rods and chute crank installed.

2. HANDLEBAR INSTALLATION

The handlebars are attached to the holes in the side of the

frame. Install a 59022 cap screw (3/4" long), a 64123 flat

washer and 63003 lockwasher in the lower hole on each side

of the frame. Do not tighten. The end of the handlebars are

slotted. Slip these slotted ends over the cap screws just in

stalled. Position the handlebars under the flat washer. Insert

a 59069 cap screw (1-1/4" long), 64123 Washer and 63003

lockwasher through each of the upper holes in the handlebars.

Hold the handlebars up in a comfortable position and tighten

all hardware.

3. THROTTLE CONTROL

Models 932001 and 932004 have the throttle controls lo

cated on the engine. Models 932006 and 932007 have the

throttle control installed on the handlebar panel. Run the

throttle cable along the inside of the left handlebar and up

under the heater box. Connect the bent end of the wire to the

throttle arm of the carburetor. Place the throttle in the fast

position, push the throttle arm up, and clamp the cable with

the screw and clamp "on the engine. Check by moving the

throttle back and forth. Throttle arm should move top to

bottom of travel. Install 69099 clamp to secure throttle

cable to handlebars.

4. WIRING HARNESS

The wiring harness is supplied attached to the engine. Run

this harness from the engine, up the left handlebar, to the

key switch. Connect wire to terminals on the key switch.

Secure the wiring harness to the left handlebar with throttle

control clamp (69099).

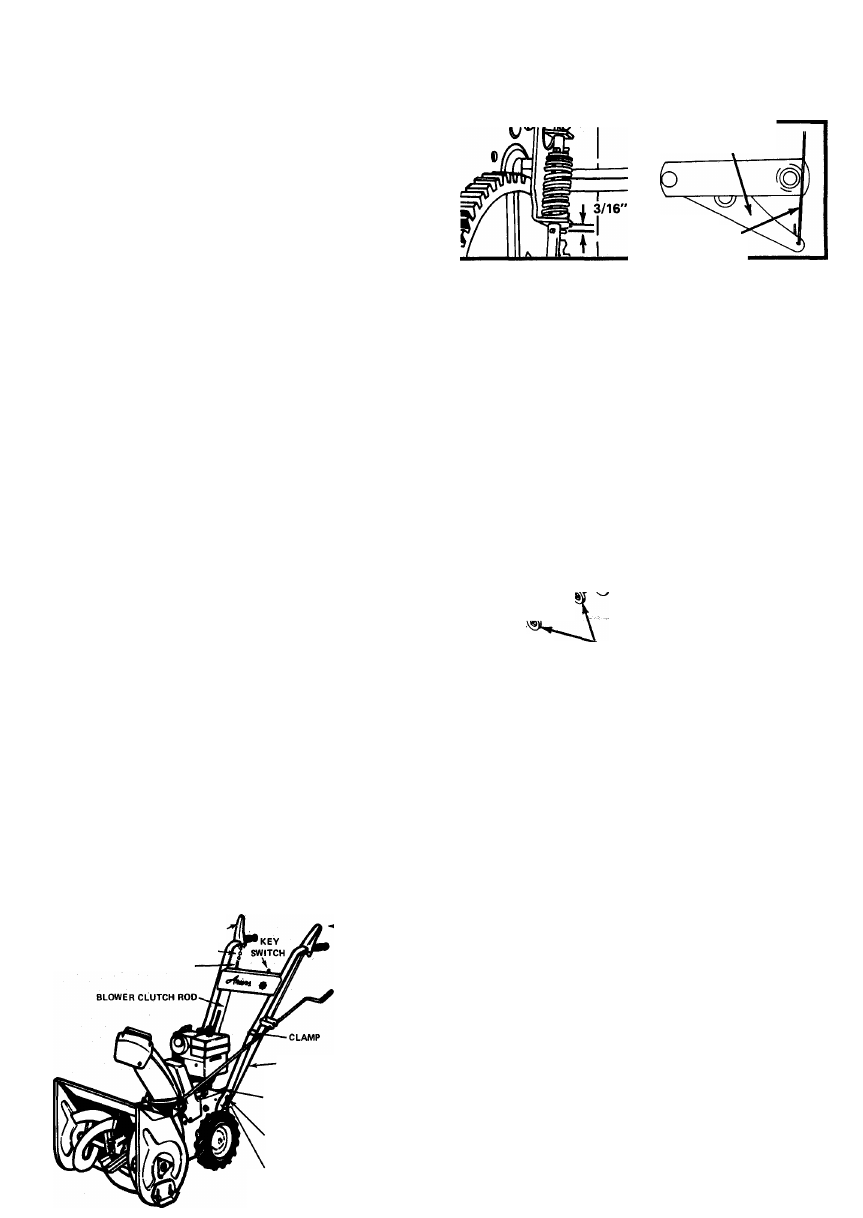

5. TRACTION CLWTGH ROD

The traction clutch rod is shipped loose in the carton. To

install the rod, place the speed selector in third speed; Insert

the bent end of the clutch rod into the hole in the clutch

handle on the left handlebar. Insert the straight end of the

clutch rod into the hole in the rod adapter in the clutch

bracket at the left rear of the frame. Hold the clutch handle

all the way down; raise the clutch bracket up to 1/16 inch of

the frame; now tighten the rod in place with the setscrew in

the rod adapter.

This adjustment can be checked by removing the bottom

cover. With the clutch handle fully depressed the clearance

between the roll pin and the bracket should be 3/16 inch.

See Figure 11. Loosen the setscrew and readjust if required.

6. BLOWER CLUTCH ROD

Install the blower clutch rod by hooking the end of the

clutch rod up through the hole in the blower clutch

lever on the right rear of the frame, see Figure 12. Connect the

BLOWER CLUTCH

CHAIN .

SPRING-

TRACTION

CLUTCH

FIGURE 10

■TRACTION

CLUTCH ROD

WIRE HARNESS

'1-1/4" CAPSCREW

IN UPPER HOLE

3/4" CAPSCREW

IN LOWER HOLE

spring end of the clutch rod to a link in the chain on the

handle. Select a link that will allow the spring to extend

slightly when the clutch handle is fully depressed.

BLOWER

CLUTCH LEVER

BLOWER

CLUTCH ROD

FIGURE 11

7. CHUTE CONTROL CRANK

FIGURE 12

The chute control crank Is shipped fully assembled and in

place in the bracket. Install as follows: Bolt the crank clamp

in place on the left handlebar. See Figure 1.

Position the worm clevis on the bracket on the blower

housing. Place external tooth lockwasher between worm

clevis and bracket. Adjust in slot so that there is a little

clearance between worm and gear teeth on blower collar.

Secure the worm clevis with the carriage bolt (already in

place on the clevis). Use a lockwasher (63023) and a 5/16-18

nut (65015) under the bracket. See Figures 1 and 2.

Rotate the discharge chute through its full travel to see

that it turns easily. Readjust the position of the worm clevis,

if required.

rla

STIC

WASHER

\ CARRIAGE BOLT

ADJUST FOR PROPER

DEFLECTOR TENSION

^

WAVE WASHER

?

1.0CKNÜT

ii;

ER

CAR

FLAT WASHERS

FIGURE 13

EXTERNAL

TOOTH

LOCKWASHER

8. DEFLECTOR

The deflector is shipped in place on the discharge chute but

must be raised into operating position. Remove the locking

hardware from the discharge chute. Raise the deflector up

into position. Re-install the hardware as shown on Figure 13.

Adjust the nut to apply sufficient tension so the deflector can

be easily moved by hand but will still hold position when

blowing snow.

9. BLOWER GEAR CASE

The blower gear case is factory lubricated and should re

quire no lubrication by the dealer. Full instructions for

checking are given in the LUBRICATION section of this

manual. Page 7.

10. ENGINE

Before starting engine, fill the crankcase with Ariens

Sno-Thro oil 5W-20 for snow blower operation below 40°

F. Use Ariens Gard-N-Oil 10W-30 for operation above 40°

F. Refer to Engine Owners Manual for appropriate substitutes.

-

12

-

11. TIRE PRESSURE

Models 932004, 932006 and 932007 are equipped with

pneumatic tires that have been over inflated for shipping

purposes. Reduce pressure to 12 to 20 PSI before operating.

Tire pressure of 20 PSI is recommended for use with tire

chains.

DEALER MUST MAKE SURE ALL SAFETY DEVICES AND

GUARDS ARE IN POSITION AND OPERATING PROP

ERLY. DEALER MUST INSTRUCT THE CUSTOMER ON

SAFETY PRECAUTIONS, OPERATING, CARE AND MAIN

TENANCE. FILL OUT PREWARRANTY REGISTRATION

AND MAIL TO ARIENS COMPANY.

{