Electrolyte level, Charging, Adjustments – Ariens SNO-THRO 924326-ST1336LE User Manual

Page 17: Discharge chute deflector, Deflector remote, Runners, Scraper blade, Chute crank

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Electrolyte Level

Every 25 hours or each week check electrolyte level of

each cell by removing caps one at a time. The electrolyte

level should be at level indicator. Use distilled water to fill

each ceil if needed.

IMPORTANT: When distilled water is added to battery

during freezing weather, it must be charged to mix water

with electrolyte or water will remain at top and freeze.

Charging

Place unit on a level surface, shut off engine and open

battery compartment (Figure 5).

1. Disconnect negative {-) cable first, then positive (+)

cable.

2. Loosen wing nut and remove battery.

3. Place Battery on bench or other well ventilated place

where electrolyte spill will not create damage.

4. Remove caps and fill each cell to level indicated with

electrolyte at 1.265 specific gravity and SO'^F (27°C).

5. Let battery stand for one half hour.

6. Check electrolyte level and add more if necessary.

7. Connect positive (+) lead of charger to positive (+)

terminal, and negative {-) lead to negative (-) terminal.

8. Charge the battery at two and a half amps for ten

hours or until all cells are gassing freely and the

specific gravity is constant over three 30 minute

intervals.

9. Immediately after charging, check electrolyte level. If

low, add distilled water to bring cell up to required level.

10. Replace caps finger tight, wash off and dry battery.

11. Reinstall battery into unit and connect positive (+)

cable first, then negative {-) cable.

A

djustments

Discharge Chute Deflector

To adjust, loosen then retighten hardware to desired

deflector drag force (Figure 5).

Deflector Remote

Adjust as required at clevis end and/or cap pivot cable

end fitting.

Runners

Runners should be adjusted (Figure 12) as conditions

require. Raising or lowering runners controls distance

scraper blade (auger/impeller housing) is held above

surface being cleared.

1. Position unit on a hard, flat, smooth level surface.

2. Adjust runners by inserting a spacer of desired

thickness under center of scraper blade, loosen

hardware, slide runners to flat surface. Allow 1/8"

(3mm) between scraper blade and hard smooth

surfaces. Allow 1-1/4" (30mm) between scraper

blade and uneven surface(s). Retighten hardware.

2. Runner Hardware

Figure 12

NOTE; Keep housing level by adjusting runners equally.

Uneven runners make unit difficult to steer and results in

uneven clearing.

Scraper Blade

IMPORTANT: Damage to auger/impeller housing wilt

result if blade wears down too far.

Scraper blade is adjustable to compensate for wear.

To adjust scraper blade:

1. Tip unit back onto handlebar, support housing and

loosen nuts retaining blade. With runners adjusted to

their full up position, reposition scraper blade down,

flush with runners, and tighten lock nuts.

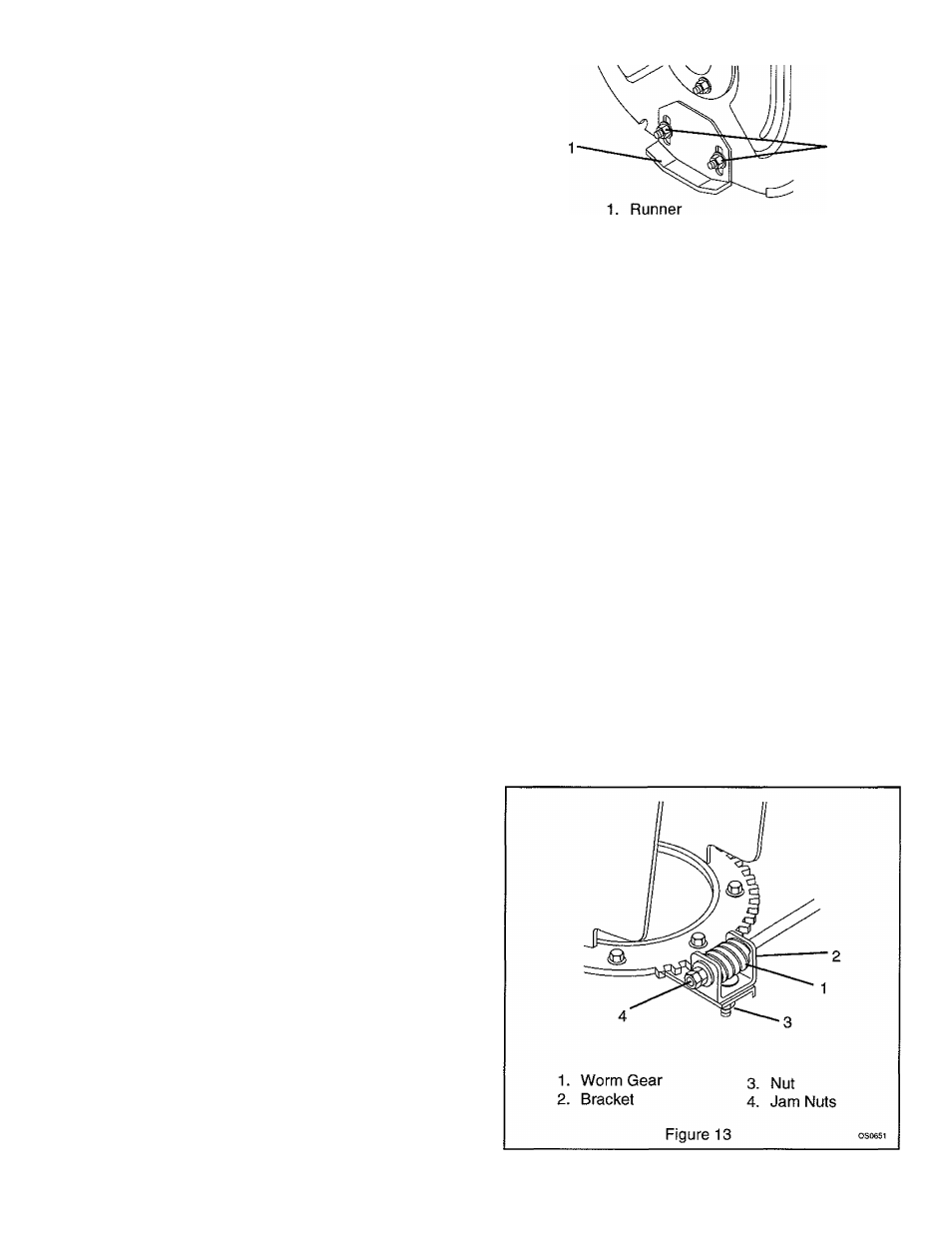

Chute Crank

Smooth and easy rotation of properly lubricated chute

with crank (without binding) is obtained by adjusting

clearance between worm (Figure 13) and discharge

chute gear teeth.

1. To adjust, loosen nut on bracket supporting worm,

position worm to fully engage (without binding), gear

teeth on discharge chute and tighten nut.

To prevent discharge chute from rotating by Itself when

unit is being operated, tighten jam nuts on end of crank

rod to put increased tension on worm gear.

Rev. 9/98

Ariens® 924 Sno-Thro

13