Traction drive belt, Attachment drive belt, Traction drive belt attachment drive belt – Ariens SNO-THRO 924326-ST1336LE User Manual

Page 14: Atitniliie

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

T

raction

D

rive

B

elt

Atitniliie

nt rtQPn

**

ROTATING PARTS can cut off body

parts. Keep hands and feet away.

Loose clothing, long hair or scarves can

get caught in rotating parts and cause

death or serious injury.______________

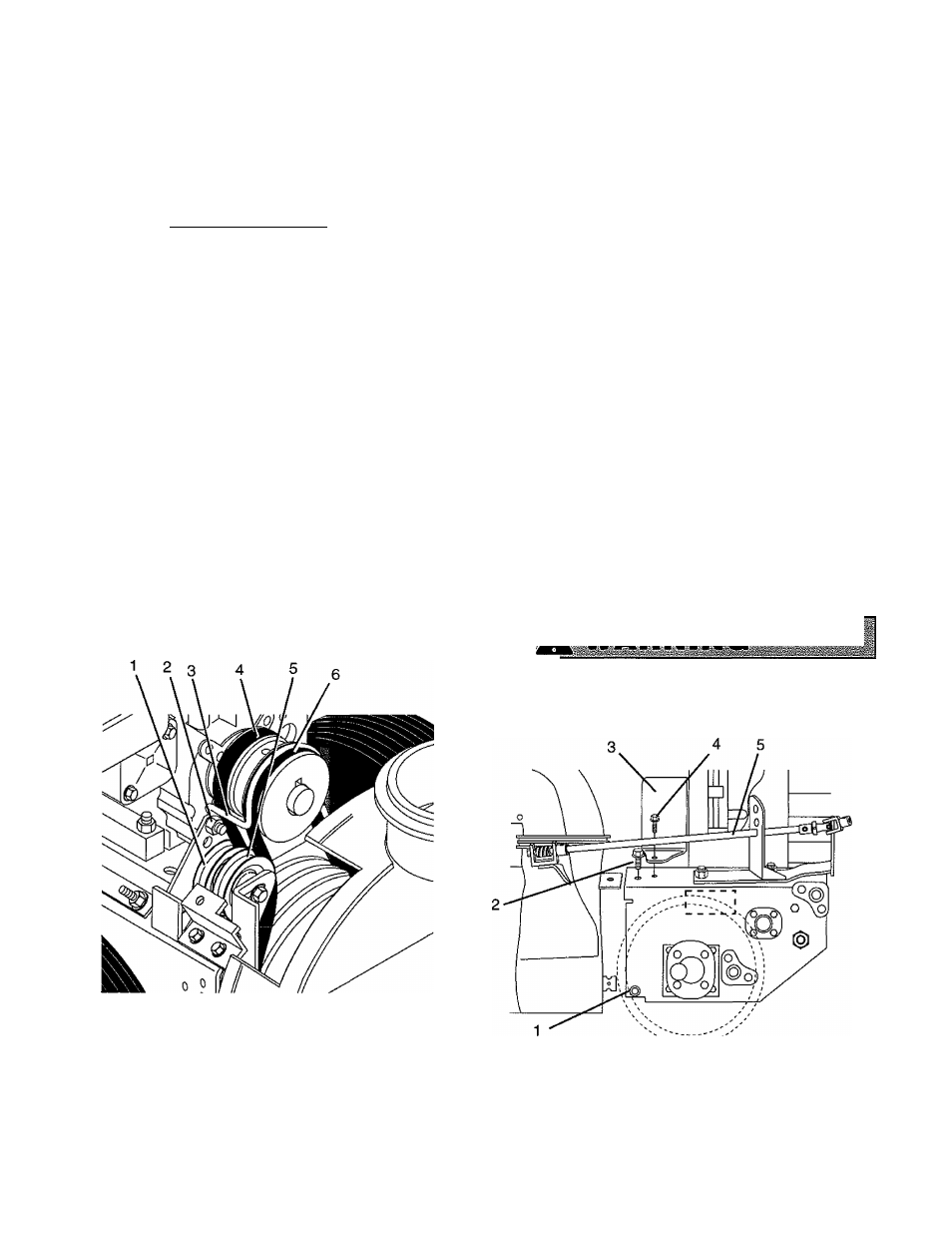

NOTE: Housing and frame must be tipped apart and

attachment drive belt removed from engine sheave in

order to change traction drive belt (Figure 6).

1. Pull idler away from belt and remove belt from idler

pulley, engine and driven pulley (it may be

necessary to turn engine pulley using rewind

starter).

2. Rotate belt fingers out and away from belt and pulley

by removing one cap screw and loosening the other.

IMPORTANT: Use care when rotating the belt fingers to

prevent deformation of parts.

NOTE: To gain clearance engage traction clutch and if

necessary pull back attachment idler arm clevis pin.

3. Replace traction drive belt and belt fingers in reverse

order making sure pulleys align. If alignment is

necessary, loosen engine pulley set screws,

reposition pulley and retighten set screws. Check

alignment of attachment driven pulley and align if

necessary.

1. Traction Belt Idler

2. Cap Screw

3. Beit Finger

4. Attachment Belt Idler

5. Traction Drive Belt

6. Attachment Drive Belt

Figure 6

A

ttachment

D

rive

B

elt

For Attachment Drive Belt Replacement (Figure 7):

1. Shut off engine and allow to cool completely.

2. Remove two screws securing belt guard to unit and

remove belt guard cover.

3. Remove hardware fastening worm gear bracket to

housing (Figure 13).

4. Loosen cap scews and carefully rotate belt fingers

out and away from belt and pulley (Figure 6).

Remove attachment drive belt (Figure 7) from engine

pulley (it may be necessary to turn engine puiley

using rewind starter).

IMPORTANT: To avoid bending bottom cover, when

tipping unit apart, support handlebars firmly or tip unit up

on housing and remove bottom cover by removing four

cap screws before separating unit.

5. Separate housing from unit. Remove cap screws

securing housing to frame (one on each side). Tip

housing and frame apart on pivot pin.

6. Remove attachment drive belt from sheave (hold

brake away from belt).

7. Replace attachment drive belt in reverse order

making sure sheaves align. If alignment is

necessary, loosen attachment sheave set screws,

reposition sheave and retighten set screws.

8. Replace worm gear bracket and adjust chute crank.

L9___________ ■ ■■

IMPELLER BRAKE MUST DISENGAGE when clutch

is engaged. Brake must be at least 1/16" (1,6 mm) to

1/8" (3,2 mm) minimum from belt when disengaged.

1. Pivot Pin

4. Bolt

2. Housing Cap Screws 5. Chute Crank Rod

3. Beit Guard Cover

Figure 7

C

1 0

Ariens® 924 Sno-Thro

Rev. 9/98