Asus 136-480A User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

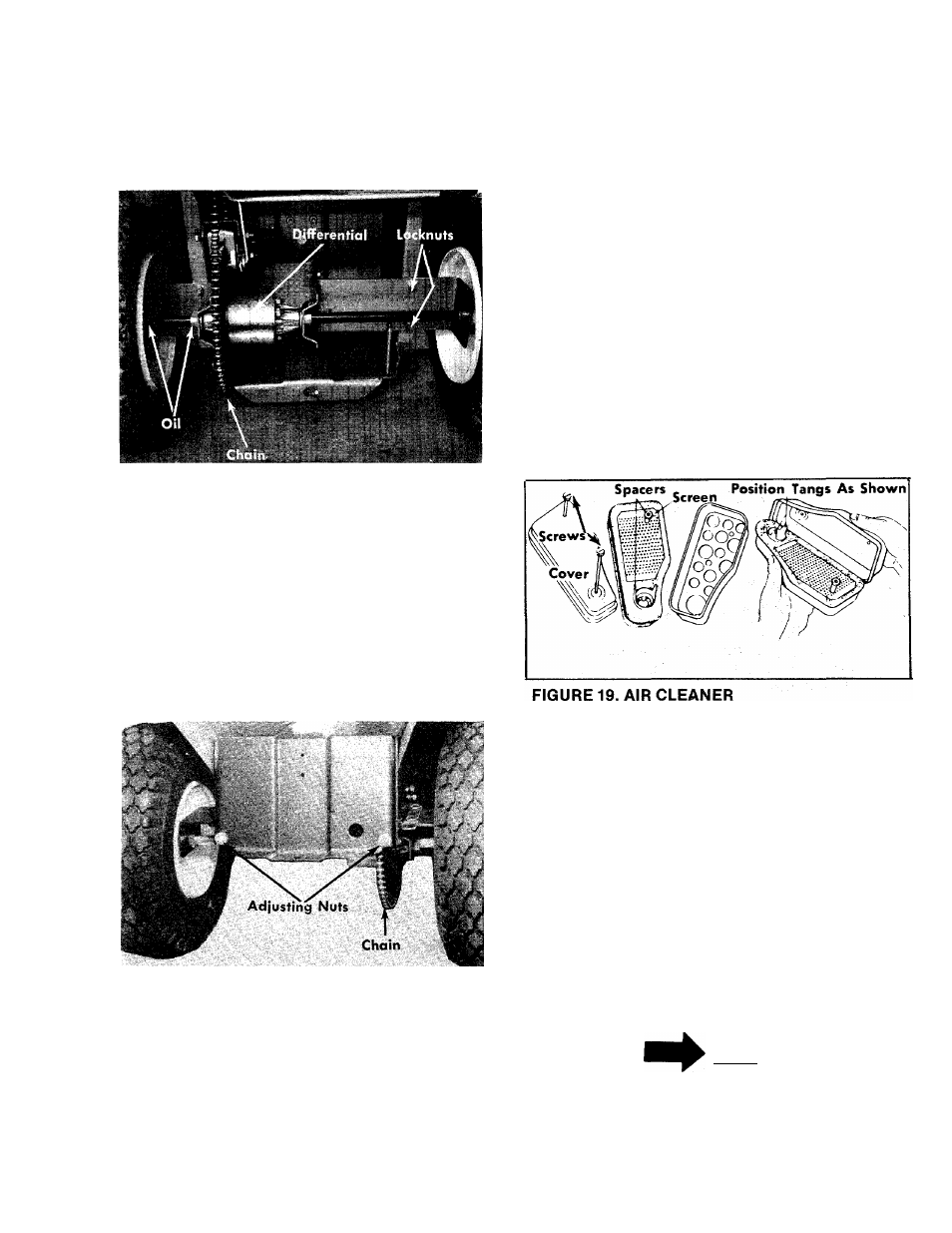

The chain can be lubricated by wiping it with an

oily rag.

The differential and transmission are sealed at the

factory and require no further lubrication.

FIGURE 17. REAR AXLE ASSEMBLY

CHAIN ADJUSTMENT

To tighten the chain, loosen two locknuts on each

side of rear axie as shown in figure 17.

Tighten the adjusting nuts (figure 18) equally on

both sides. Tighten until the chain has Va inch

siack between the sprockets.

The adjusting nuts can be tightened individuaiiy

to aiign the axle.

Tighten the 4 locknuts after the adjustment is

made.

When assembling the air cleaner, make certain

the iip of the foam element extends over edge of

the air cleaner body. The foam element will form a

protective seal.

Step 1. Remove two screws and lift off complete

air cleaner assembly.

Step 2. Remove screen and spacers from foam

element.

Step 3. Remove foam element from air cleaner

body.

Step 4. a. Wash foam element in kerosene or

liquid detergent and water to remove

dirt.

b. Wrap foam in cloth and squeeze dry.

c. Saturate foam in SAE 30 engine oil,

then squeeze out excess oil.

d. Assemble parts, fasten to carburetor

with screw.

FIGURE 18. CHAIN ADJUSTMENT

CLEANING ENGINE AND BLADE HOUSING

Any fuel or oil spilled on the machine should be

wiped off promptly. Grass, leaves, and other dirt

mustoot be left to accumulate around the cooling

fins of the engine or on any part of the machine.

Clean the underside of the blade housing after

each mowing.

BELTS

Check that belts are free of oil or dirt. Wipe the

belts periodically with a clean rag.

AIR CLEANER

Under normal operating conditions, the air

cleaner, located on top of the carburetor, must be

serviced after every ten hours of use. Under

extremely dusty operating conditions the air

cleaner must be serviced after every hour of

operation. Refer to figure 19.

NOTE

Belt tension is automatically main

tained by the spring on the variable

speed bracket on the drive belts and

the belt tension on the deck belt is

maintained by the two deck springs.

11