Sears KENMORE 1700 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

4

Turn handle clockwise until it has pierced the water

line and valve is completely closed {Fig. 16).

5

Partially uncoil the tubing. Slide the brass compres

sion nut over the tubing. The threads in the nut must face the

tubing end. Place the brass compression sleeve as shown in

Fig. 16. Slip brass insert into end of tubing.

__6 Insert the tubing end into the saddle valve at

threaded stem “A” (Fig. 16) as far as it wilt go. Thread the

brass oompression nut onto the valve, then tighten gently with

a wrench. Take care not to overtighten the nut.

FIG. 16

Brass Compression Sleeve

/

Brass Insert

Brass

Compression Nut

Water Pipe

"A"

Rubber Gasket

(Stem Up)

MOUNTING SADDLE VALVE

__ f Unwind the rest of the tubing. Take care not to kink

it. Run the tubing along flat surfaces to the humidifier. Support

the tubing as needed to avoid contact with furnace.

_

8

Close previously opened faucet. Turn on main wa

ter supply. Place a pail under the end of the tubing. Open the

saddle valve. Flush the line. Make sure there are no leaks along

the line or at the valve. Turn valve off.

9 Complete installation of water supply by first sliding

plastic compression nut onto the water supply tubing. Insert brass

insert into the end of water supply tubing. Insert the tubing into

humidifier valve body, making sure it is fully seated. Tighten plas-

tio nut securely, finger tight (no wrench) (Fig, 17).

Plastic Compression Nut

Brass Insert

— Plastic

Water Line

WARNING:

Brass Insert Must Be Installed

10

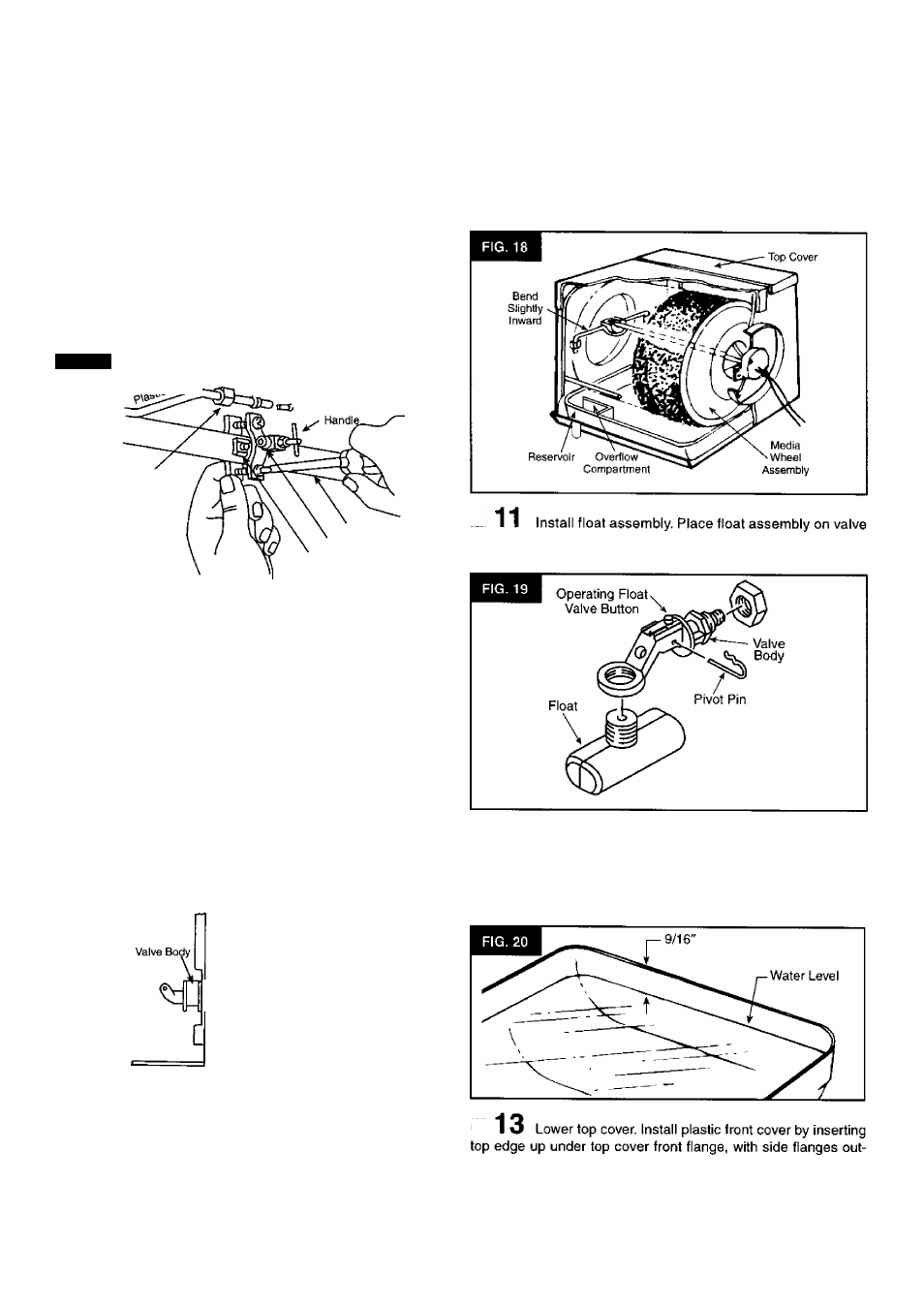

Install reservoir, making sure overflow drain is on

left side. Install media wheel. Be sure that media wheel is prop

erly engaged with the media motor and that media wheel shaft

is in groove in plastic bearing (Fig. 18),

NOTE:

Wire bearing support must be bent slightly inward

to insure snug engagement of media wheel with media

motor. Adjust as required by bending wire slightly inward

before installing media wheel. (Be careful not to overbend

as too much tension may cause media wheel shaft to pop

out of plastic bearing.)

body; align hole. Slide pivot pin through holes to fasten. Float

should have slight up and down movement (Fig. 19).

12 Open saddle valve and allow reservoir to fill. Check

water level (Fig. 20), If adjustment is necessary, turn off water

and remove float assembly. See instructions on bottom of float.

To raise water level, turn float clockwise viewing bottom of float.

Water should be 9/16" below the top edge of the reservoir.

side casing. Swing bottom of cover in against case and iower

down against flange.