Sears 385 User Manual

Page 59

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

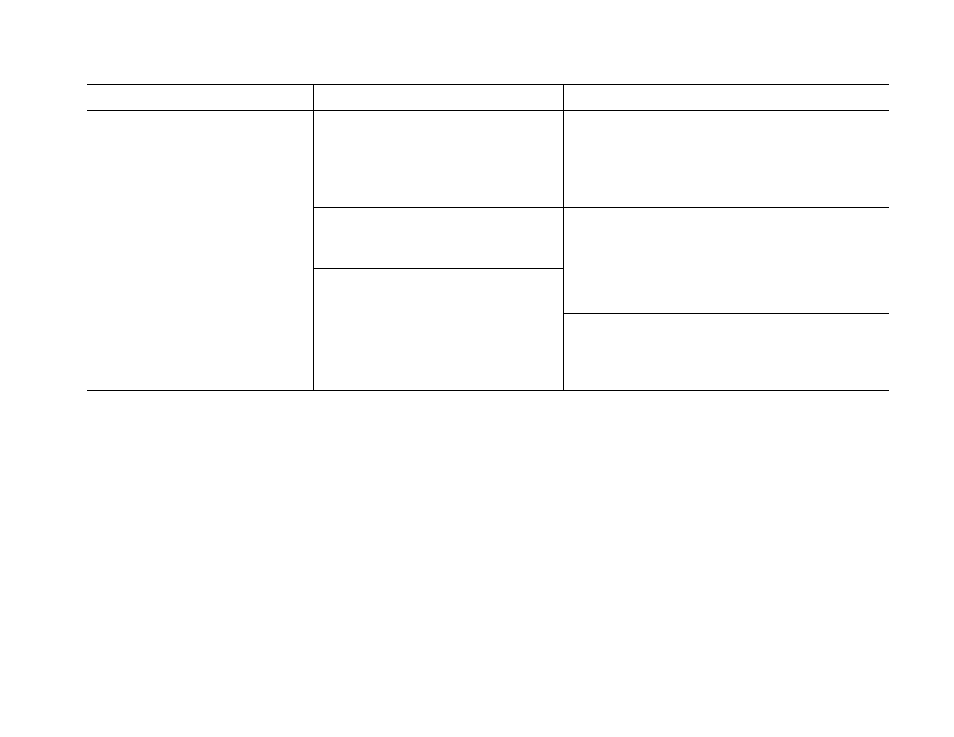

SECTION 4. PERFORMANCE PROBLEMS CHART

What to Do When

PROBLEM

PROBABLE CAUSE

CORRECTION

Itregiildi SliTches

Incorrect size needle.

Improper threading.

Loose upper thread tension.

Pulling fabric.

Loose presses foot.

Unevenly wound bobbin.

Nicks or burrs at hole of needle plate.

Choose correct size needle for thread and fafrnc.

Rethread machine.

Tighten upper thread tension.

Do not pull fabric; guide tt gently.

Reset presser foot.

Rewind bobbin.

Replace needle plate, or polish off burrs compietRly.

Bipflking Needle

Pulling fabric.

Incorrect size needle.

Incorrect setting of needle.

Loose presses foot.

Do not pull fabric; guide it gently.

Choose correct size needle for thread and fabric.

Reset needle.

Reset presser foot.

Buncditig of Thread

Upper and lower threads not drawn back

under presses foot before starting seam.

When starting a seam be sure to draw both threads unrler and

back of presser fool about 4" and hold until a few stitches are

formed.

Pockei ing

Incorrect thread tension.

-Using two different sizes or kinds of thread.

Bent or blunt needle. .

Loose presses foot.

Fabric too sheer or too soft.

Reset thread tension.

Upper thread and bobbin thread should be same size and kind.

Insert new needle.

Reset presser foot.

Use underlay of tissue paper.

56