To install the upper handle and crank assembly, Assembly – Sears Craftsman 536.886531 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY

TO INSTALL THE UPPER HANDLE

AND CRANK ASSEMBLY

e

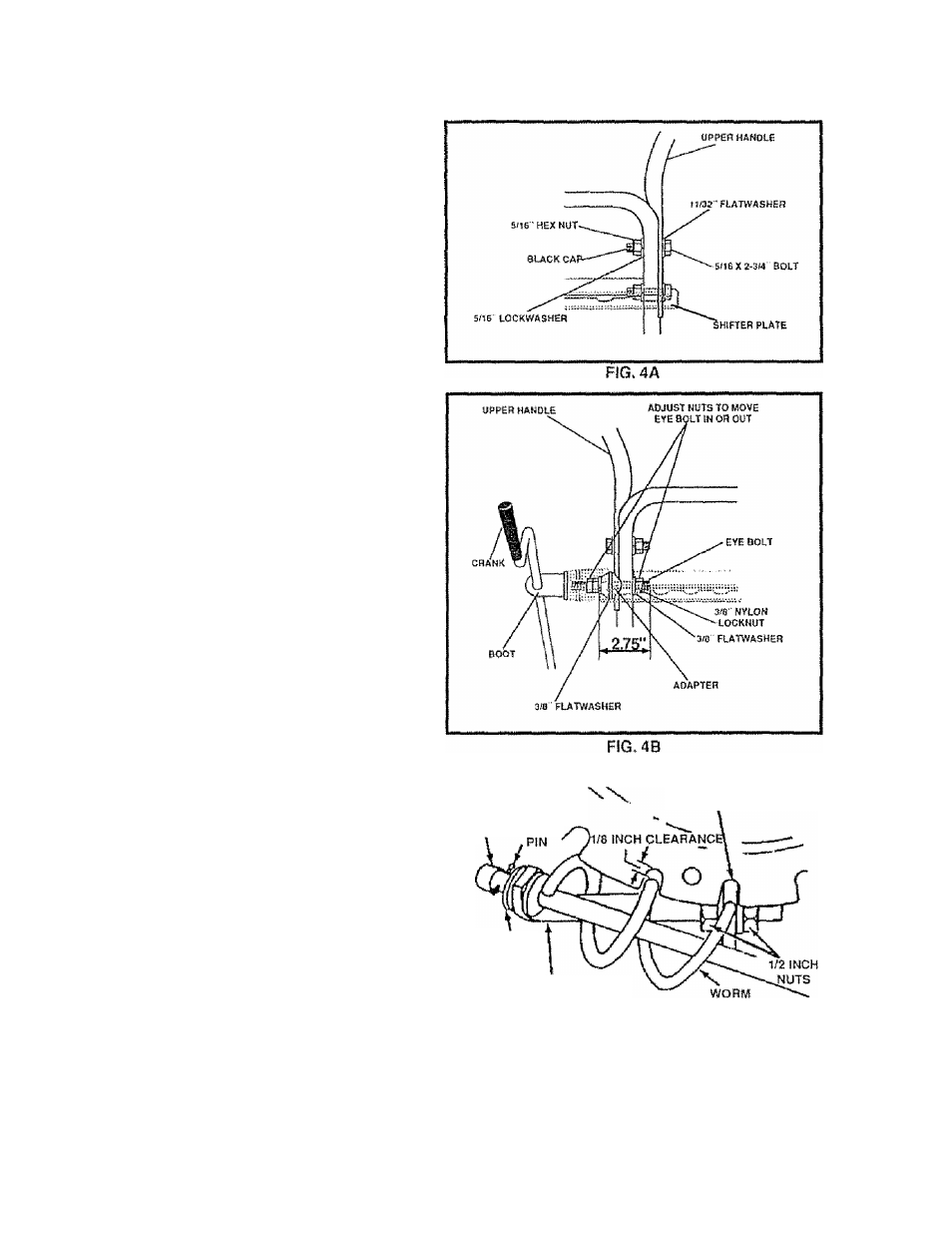

Remove

the

screws,

flaiwashers,

lockwashers,

and

hex nuts securing the shifter piate in the lower holes

of the lower handle and move shift lever to 3rd gear

® Loosen, but do not remove, the screws, flatwashers,

lockwashers, and hex nuts in the upper holes ol the

lower handle

® Raise upper handle into operating position. Upper

handle should be to the outside of the lower handle

and shifter plate to the inside

® Replace the right hand screw, tiatwasher, lockwasher,

and hex nut through the handle and shifter plate Do

not tighten until all boils are in place

NOTE: Unless you have the assistance ol another per

son, it may be easier to install one side of the handle at a

time.

® Remove the 3/8" nylon locknut and flatwasher from

the eye boll assembly (on the chute crank assembly

earlier) Check to make sure the two 3/8" jam nuts are

tight. The jam nuts should be 2 75 inches from the end

of the eye bolt (See Fig. 4B)

® Remove the plastic bag, the plastic cap, the cotter pin

and the washer from the

crank

assembly and set

aside (See Fig 5)

@ Rotate the notched section oi the discharge chute

toward the crank-adjusting rod (See Fig 5)

® install the wormed end of the crank through the hole

in the adjusting rod and secure the end with the

tiatwasher and colter pin, as shown in Fig 5

® Bend the ends of the cotter pin around the rod and

reinstall the plastic cap

® Install eye bolt through lower hole in the left hand side

of the handle and shifter plate (See Fig 4B)

® install the 3/8" flatwasher and the 3/8’’ nylon locknut

loosely on the ey bolt as shown in Fig 4B

® Tighten the eye bolt installed earlier, keeping eye in

line with the rod while tightening the inside securely

® Tightenthe screw, flatwasher, lockwasher and hex nut

at the lower right hand hole (See Fig 4A)

NOTE: Make sure the cables are no( caught between

the upper and lower handle

® Tighten two upper handle bolls

® Rotate the chute crank fully clockwise and lully counter

clockwise The discharge chulé should rotaie fully with

approximaiely

1/8

inch

clearance

beiween

the

worm

and the bottom ol the notch (See Fig 5)

PLASTIC \

CAP COTTER

NOTCHED SECTION

FLATWASHER

CRANK ADJUSTING ROD

FIG. 5

® If the chute crank needs to be adjusted, go to the

Service and Adjustments section on page 17 Screws

securing chute clips a! the base of the chute should be

slightly loose for easy rotation

NOTE: Be sure the crank does not touch the side of the

engine or the cover will be scratched.