General recommendations, After first use, Snow thrower – Sears Craftsman 536.886531 User Manual

Page 15: Lubrication - every five hours, Lubrication - every ten hours, Lubrication > every 25 hours, Lubrication - before storage, Genera! recommendations, Customer responsibiüties

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

GENERAL RECOMMENDATIONS

CUSTOMER RESPONSIBIÜTIES

The warranty on this snow thrower does not cover items

that have been subjected to operator abuse or negli

gence To receive full value from the warranty, operator

must maintain snow thrower as instructed in this manual.

Some adjustments v/itl need to be made periodically to

properly maintain your snow thrower

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each

season

AFTER FIRST USE

•

Check for any loose or damaged parts

® Tighten any loose fasteners

•

Check and maintain the auger

« After each use, remove all snow and slush off the

snow thrower to prevent freezing of auger or Con

trols

® Check controls to make sure they are functioning

properly

» If any parts are worn or damaged, replace imme

diately

SNOW THROWER

LUBRICATION - EVERY FIVE HOURS

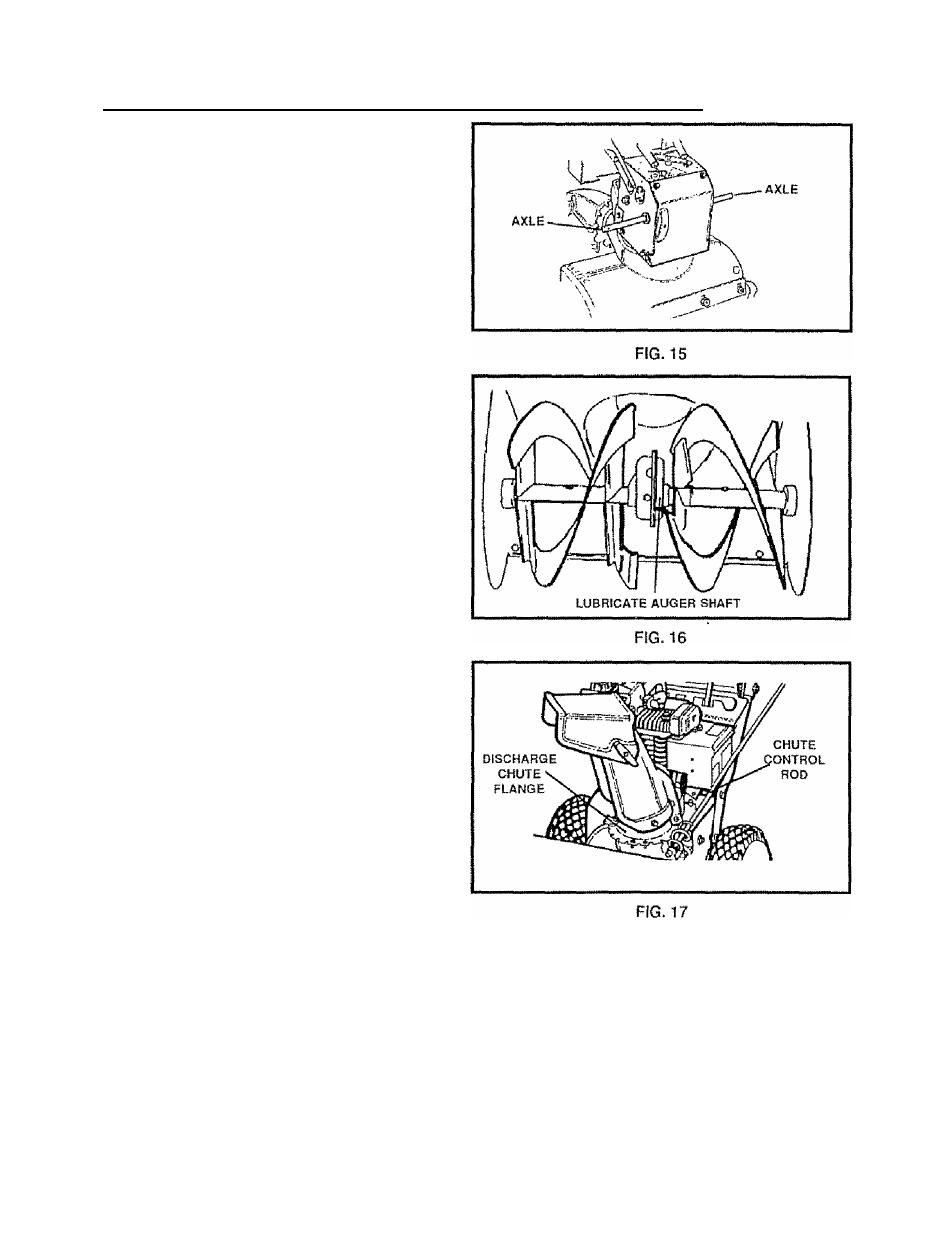

® Lubricate the flange on the discharge chute every

five (5) hours during use and before storage (See

Fig 17)

® See Lubrication Chart diagram on page 25 for lu

brication points and type of lubricanf

LUBRICATION - EVERY TEN HOURS

® Auger Shaft - For storage, lubricate auger shaft ( See

Fig 16} with a ciinging type grease such as Lubriplate

When replacing shear bolts, remove shear boils and

lubricate auger shaft (see To Replace Shear Bolt

paragraph on page 22)

•

The chute control rod, used to change the direction

of the snow discharge, needs to be lubricated ire-

quenfly and before storage (See Fig 17)

® See Lubrication Chart diagram on page 25 for lu- _

bricalion points and type of lubricant

LUBRICATION > EVERY 25 HOURS

® Disc Drive Plate - Using a hand grease gun, lubricate

with a Hi Temp EP Moly grease, zerk located be

neath the disc drive plate (See Fig 18 inset) every 25

hours and at the end of the season and/or before

storage To grease zerk, turn disc drive piate clock

wise by hand until zerk is clearly visible at front

center DO NOT overfill or allow grease lo come in

contact with the disc drive plate or friction wheel or

damage will result Fill zerk only until grease becomes

visible below bearing assembly located under grease

zerk. See Lubrication Chart on page 25

LUBRICATION - BEFORE STORAGE

® Remove both wheels, grease (any automotive type

grease) both axles (See Fig 15) and replace wheels

Do this al least once a year and/or prior lo storage

15