Operation, Hints for good spraying results – Sears 919.15516 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CONVERTING TO REMOTE PRESSURE FEED

1. Remove suction cup and lid assembly by loosening &

removing the swivel nut (30). This will require a %"

open end wrench.

2. The spray gun is now ready to be connected to any

pressure feed tank with a standard %" straight pipe

female connection (not included).

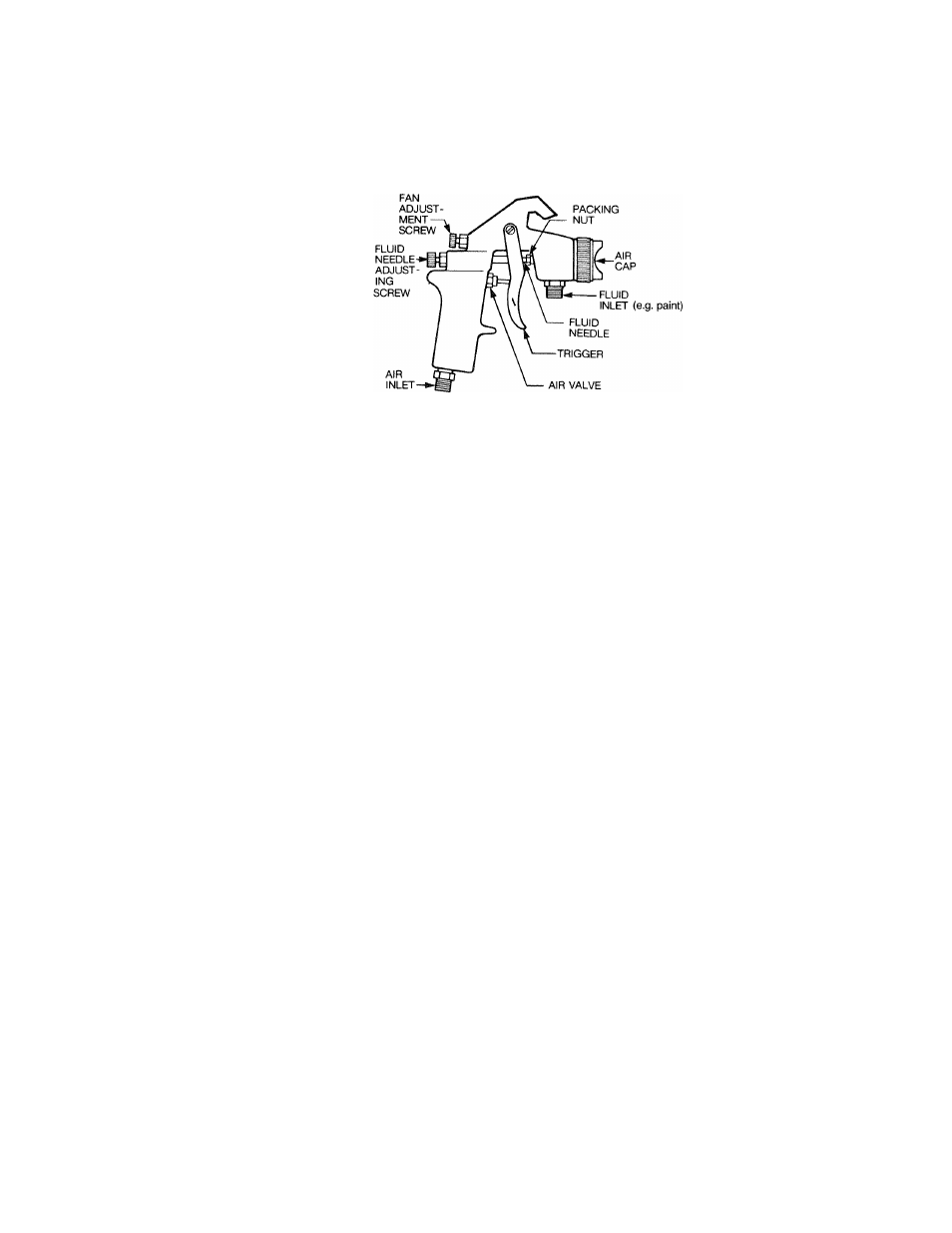

Refer to this picture when reading

the

“Preparation for

Spraying” and “Operation” sections.

OPERATION

1. Shut off fluid flow through gun by turning fluid needle

adjusting screw (18) clockwise as far as it will go. Do

not force.

2. Keep the air pressure as low as possible.

3. For fan pattern open (turn counterclockwise) the fan

adjustment screw until it stops. This is the full open

position. For round pattern, the fan adjustment screw

should be turned clockwise until the desired pattern is

achieved.

4. Hold the trigger back and gradually open the fluid

needle adjusting screw until a desired pattern is

obtained.

5. Trigger the gun quickly (one second on, then release).

Spray a small test pattern.

6. If the gun sprays too fast (paint runs or sags), lower

the air and fluid pressure. If too slow, increase pres

sure. Adjust to balance pressure.

Note

Refer to the troubleshooting guide on page 8.

This guide is useful in setting up your spray gun

as well as troubleshooting problems.

• Hold the gun perpendicular to the surface, 6" to 8"

distance.

• Follow contour of object being sprayed.

• Overlap each stroke 50%.

• Ends are feathered by triggering. That is, begin stroke

before pulling trigger and releasing just before ending

the stroke.

• Spray edges and corners first. This will reduce over

spray while providing good coverage on corners.

• Don’t arc strokes, move gun parallel to work.

HINTS FOR GOOD SPRAYING RESULTS

Your pattern should normally be shaped like this.

If not, see Troubleshooting guide, pg. 8.