Sears 625.34929 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

-- s

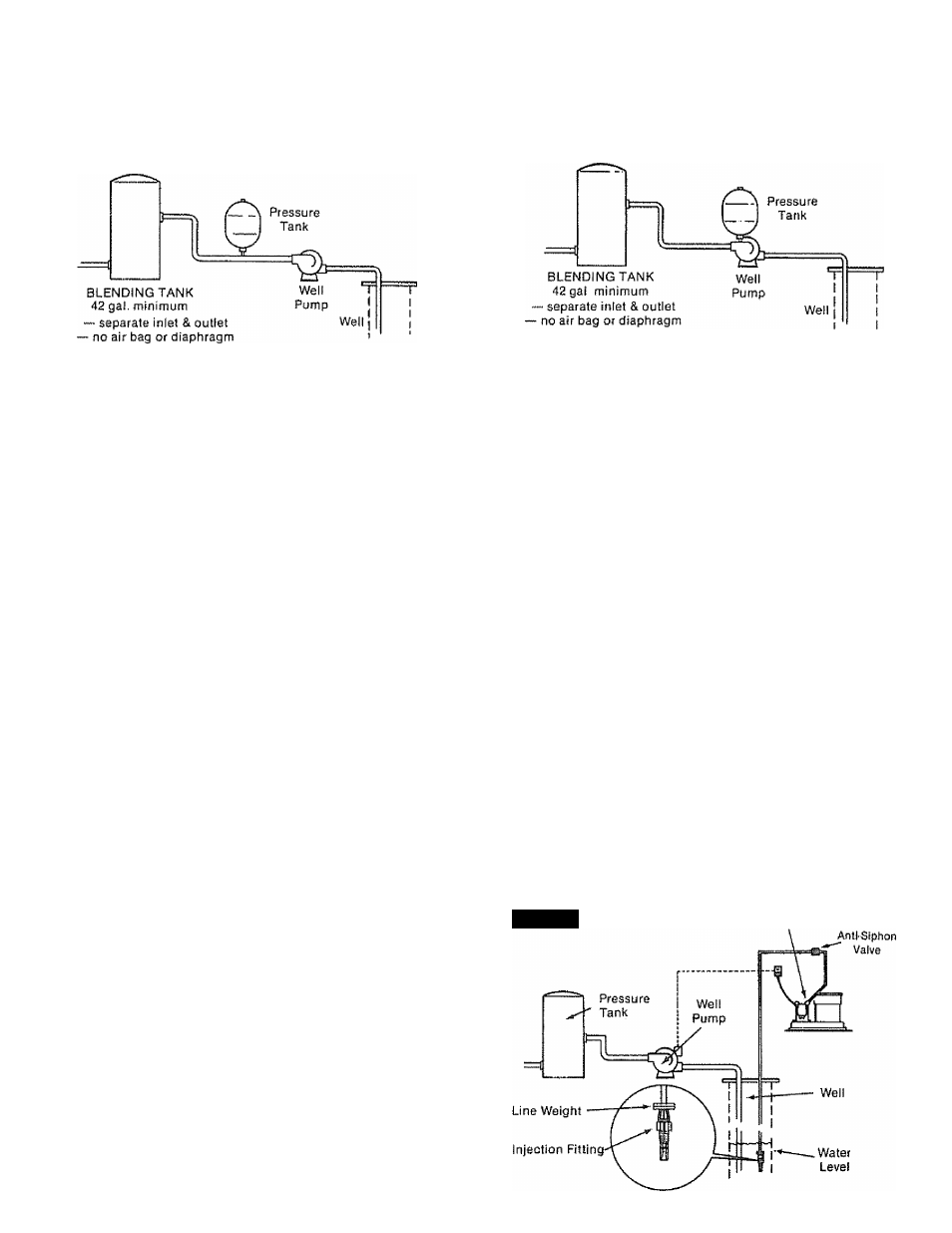

PRESSURE TANK INSTALLED “ON" THE MAIN

SUPPLY LINE

CAPTIVE AIR PRESSURE TANK INSTALLED "ON"

DISCHARGE SIDE OF WATER PUMP

GUIDES TO INSTALL YOUR SO:.lT':;;i-i ;::L=L'[';i-:-:-5LVT .iYSy-V;

® SOLUTION INJECTION INTO THE WELL CASING

1. Set the solution dispensing system in the piece

you chose to locate it. See page 7 for guides.

2. Measure for the length of tubing needed to run

from the solution pump discharge fitting down to

the water level in the weil. The tubing is stiff, so

allow enough length for longer bends. Cut both

ends of the tubing square with a sharp knife.

NOTE; The system includes 15 ft. of tubing. If more

is needed, look at the parts list on page 19. You can

use a bulkhead fitting (Key #5, page 19} to join

tubing together.

3. Remove the nut from the discharge valve (FIG.

4) on the solution pump. Slide the nut over 1 end of

the tubing. Push the tubing onto the tip of the

discharge valve as far as it will go. Then slide the

holding nut onto thevalve and tighten it with your

fingers.

NOTE: To prevent siphoning of solution, buy (see

page 19) and install an anti-siphon valve as shown

in FIG. 4. Siphoning of solution may occur when

the solution dispensing system is located above

the injection point fitting.

4. In the same way as in step 3, connect the other

end of the tubing to the injection fitting.

NOTE: Looking at FIG. 4, put some weight on the

tubing so the injection fitting will stay under water.

Large steel washers(3/8"i.D.)make good weights.

5. Lower the injection fitting down into the well.

CAUTION: In cold weather climates, you must

insulate this tubing so it will not freeze.

DO NOT REMOVE THE PLASTIC SLEEVE FROM

THE TIP OF THE INJECTION FITTING. (T IS A

WORKING PART.

SEE PAGE 11 TO MAKE THE NEEDED ELEC

TRICAL CONNECTIONS.

iiMWI

Pump Head

Discharge Fitting