Generator sizing, Service, Lubrication – Sears 390.303491 User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

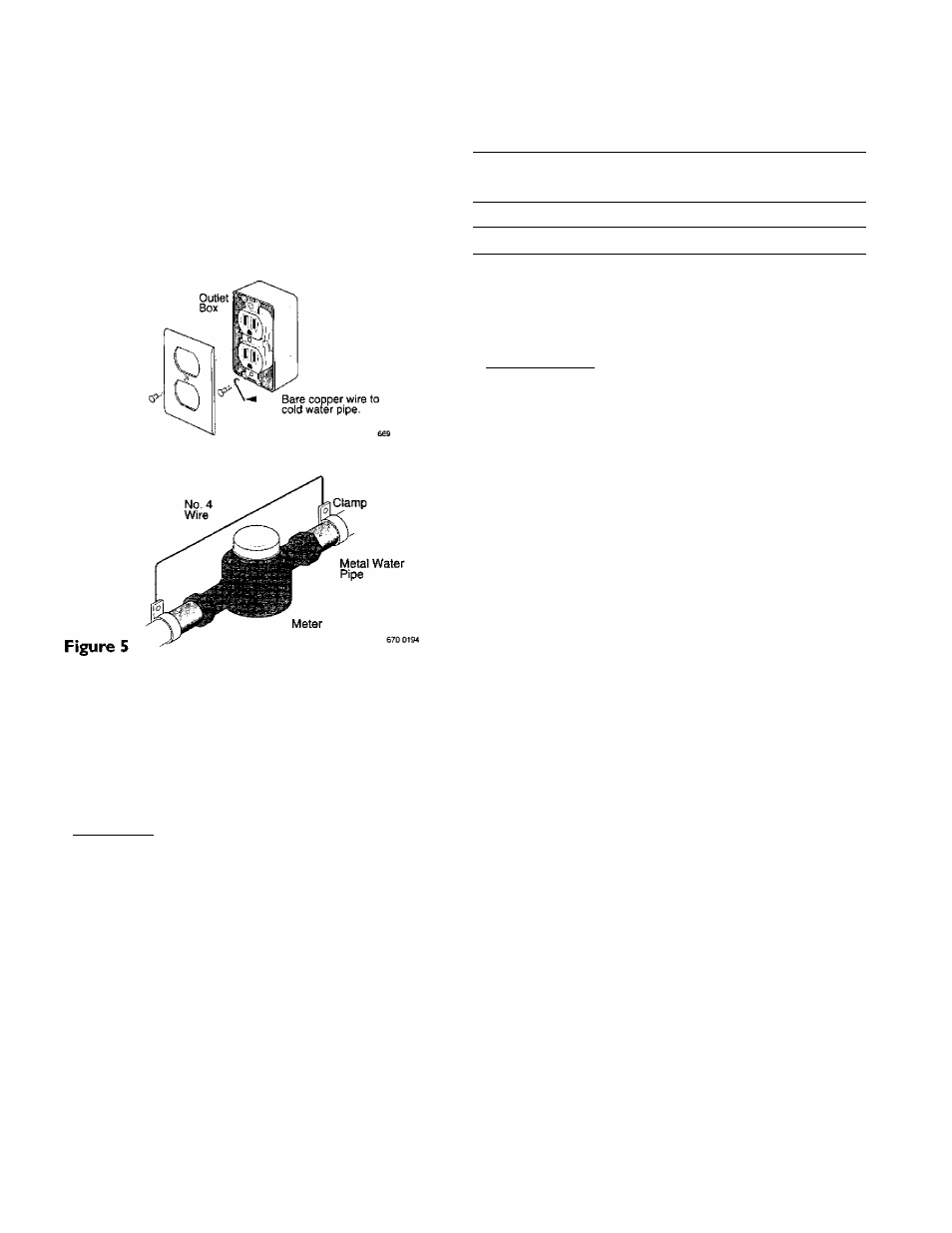

Grounding Outlet

If outlet is not groionded, install a copper wire (at least 14

gauge) from the outlet box, as shown in Figure 4, to a metal

cold water pipe. Use ground clamp on pipe.

IMPORTANT; The cold water pipe you use as a ground

must have metal continuity to electrical ground. If continuity

is interrupted by plastic, rubber, or other electrical insula

tors; such as hoses, fittings, washers or gaskets (including

water meter or pump), a metal bypass must be used. Any

electrically insulated connector should be jumped (as shown

in Figure 5), with a length of No. 4 wire clamped securely

at both ends.

GENERATOR SIZING

Figure 4

Automatic Thermal Overload Protection

This pump motor has a built-in automatic thermal overload

protector. If the motor overheats, the protector will open

and cut off power to the motor before the heat damages it

internally. The overload will reset automatically and the

pump win restart after the pump cools down below the dan

ger point.

AWARN1NG £)Q

attempt to work on the pump or

motor

if

the

overload

seems

to

have

tripped.

The

motor may restart without warning at any time. You

could be injured and the pump damped if it starts

when you are working on it.

DO NOT attempt to repair a sump pump. Take it to SEARS

for service by a qualified technician.

Below is the Engine-Generator Watt rating required to

power this pump motor. Any additional loads, such as lights,

must be added to the listed load and the generator sized ac-

cordingly.

Pump

Minimum Watt

Motor HP

Rating of Generator

1/3

2,200

1/2

2,800

SERVICE

General

A WARNING I Risk of electric shock. When servicing

pump always discoimect power to electrical outlet

and remove pump electric cord from outlet. Inspect

sump pump and system components monthly. Keep

free of debris and foreign objects.

1. If pump does not operate;

a. Check for loose plug at electric outlet.

b. Check for blown fuses or tripped circuit breakers at

fuse box/circuit breaker box.

c. Be sure nothing interferes with action of float switch.

d. If a, b, and c above check OK, plug in a light that you

know works. If it lights, take your pump to SEARS for

service. If it doesn’t light, the electrical circuit is faulty;

consult a licensed electrician.

2. Pump starts, but blows fuses/trips circuit breakers:

After disconnecting power to pump, remove it from

sump. Remove the plate from the bottom of the pump

and make sure that the impeller turns freely. Remove any

debris obstructing impeller. If pump still does not oper

ate correctly, return it to your nearest SEARS Service

Department for repairs.

3. Pump runs, but does not empty sump:

a. Clean pump intake screen.

b. Water may be entering sump faster than the pump can

discharge it.

c. Be sure vertical distance from pump discharge outlet

to discharge pipe outlet is 18 feet or less for Model

390.303302 (20 feet or less for Model 390.303491).

d. Be sure discharge pipe is not plumed or frozen.

LUBRICATION

Motor has been lubricated at the factory. It does not require

additional oil. Bronze bearing in volute housing is oil im

pregnated. It does not require additional oil.