Assembly instructions, Lubrication, Assembly instructions belt adjustment – Homelite 24666 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

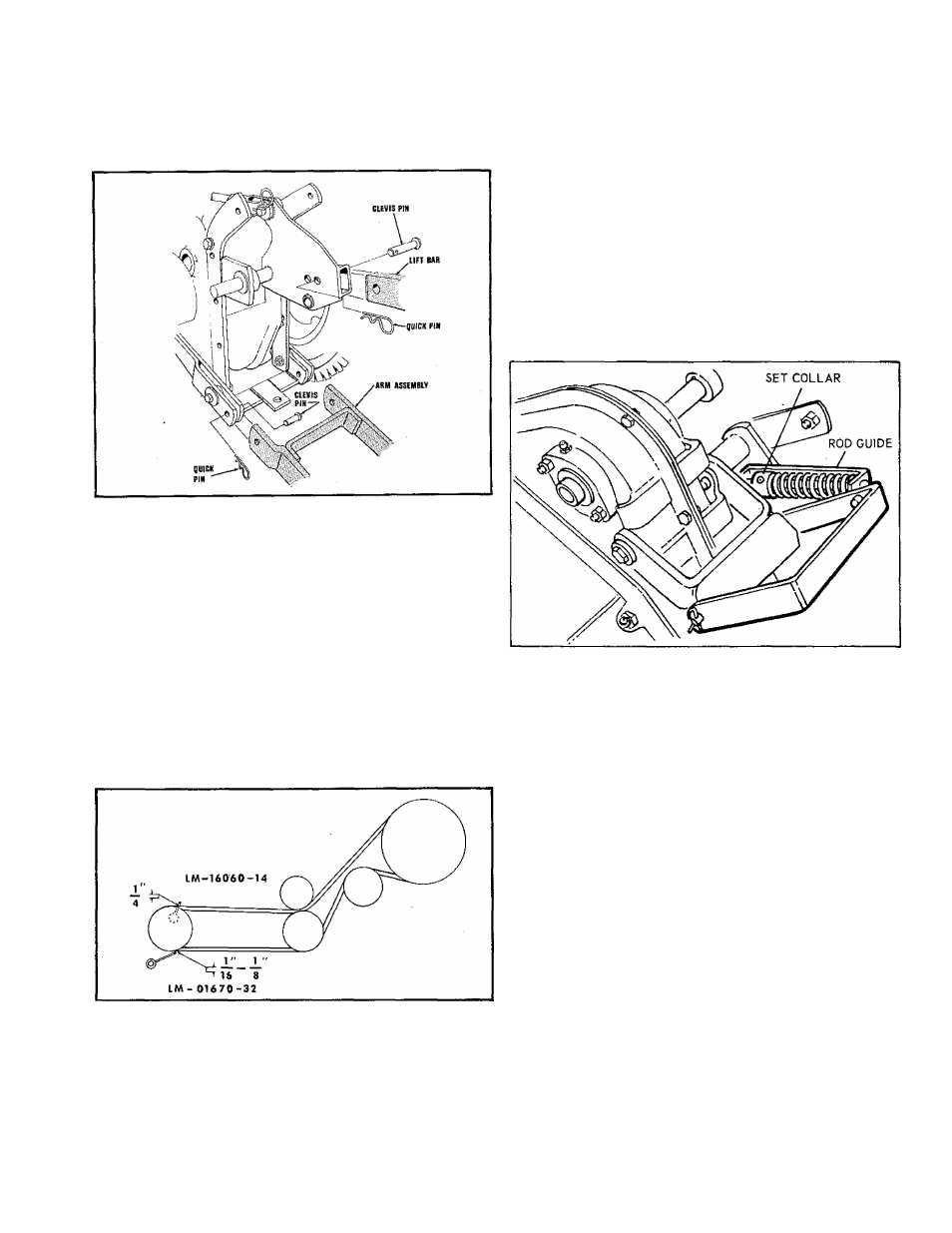

ASSEMBLY INSTRUCTIONS

BELT ADJUSTMENT

fe(

1.

Position tiller at the rear of the tractor. Place the lift

lever in the fully back position. Put the tiller lift assem

bly into the tractor lift assembly and secure with clevis

pin and quick pin.

2.

Place tractor lift lever in forward position. Secure the

tiller frame assembly to tractor with the two clevis pins

and two quick pins supplied.

3. Slide idler arm assembly onto rear lift shaft.

4. Attach lower end of idler arm assembly to hitch member

with clevis pin and quick pin.

5. Assemble pulley to power take-off (PTO) shaft on bevel

gear housing. Using existing cap screw, washers, and

nut, secure belt stop to tractor.

6. Position belt

dh

pulleys and check that the belt is seated

properly in the pulleys, and that the pulleys are properly

aligned.

LUBRICATION

The belt that transmits power from the bevelgear box to the

tiller drive shaft is designed to provide long and satisfactory

service. Because of the special design of this belt, it is

urged that it is only replaced with genuine replacement

ordered from your dealer.

Adjustment of belt tension is controlled by the set collar on

the rodguide assembly. The tensionshould be correct when

there is about 1-1/4" clearance between the collar and the

bracket of the rod guide assembly with the tiller clutch lever

engaged. To increase the tension, release the tiller clutch

lever and loosen the setscrew in the collar. Slide the collar

up toward the spring and retighten the set screw. Check

the tension by engaging the tiller clutch lever. Avoid ex

cessive tension as it will cause premature belt failure.

There are grease fittings on each housing bearing and two

90° grease fittings are on the right hand side of the housing.

These fittings should be lubricated every three hours of

operation. Use a good grade of general purpose automotive

type grease applied with a standard grease gun. (Fittings

should be wiped clean before applying any grease.) Also

apply a few drops of lubricating oil to the moving linkages

of the tiller drive assembly occasionally.

Before starting the tractor engine, place the tiller clutch

lever in the disengaged position, and raise the tiller above

the surface of the ground. With the tractor engine running,

engage the tiller clutch and lower the tiller into contact

with the ground. As the tiller works into the soil, slowly

release the tractor clutch and move ahead. When coming

to the end of a row, raise the tiller free of the ground be

fore turning around.

Effective operation of the tiller will depend in a large degree

upon the operator. For example; when intending to till a

sod area into a seed bed for gardening, it obviously will re

quire several passes over the same path to break the sod

and ground into fine particles suitable for a seed bed. De

pending on the nature of the soil, it will be desirable to altar

the depth settings for the tiller on succeeding passes until

the desired depth is reached. When tilling in soil that has

been previously worked, it may be possible to till to the de

sired depth from the start.

The depth of tilling is regulated by the ground speed of the

tractor. The slower the ground speed the deeper the tilling

action.

NOTE: When using the rotary tiller on a tractor

equipped with the power lift attachment,

the power lift attachment must be in the

float position. Operating the tiller in the

hold position will cause the tiller tines to

propel the tractor at a dangerous speed .