Start-up, J Page 7: L-ll, 3^- —-ii

Page 7: L-ll, 3^- —-ii

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 7 — Maximum Field Wire Sizes

UNIT

SIZE

VOLTS

(60-Hzy

WIRE SIZE

CONN.

38AD

024,028,034

208

230

6 AWG to 350 MCM

TB

460

575

14 AWG to 2/0

044

460

575

208

230

6 AWG to 350 MOV!

TB

CT

38 A B

054,064

208

230

6 AWG to 350 MCM

CT

460

575

6 AWG to 3/0

084

All

6 AWG to 350 MCM-

CT

CT — Compression Terminal (attached to terminal block)

TB — Terminal Block (with integral compression terminal)

TB

&-

[1]--

[E--

0--

lEh

T

I

-I -

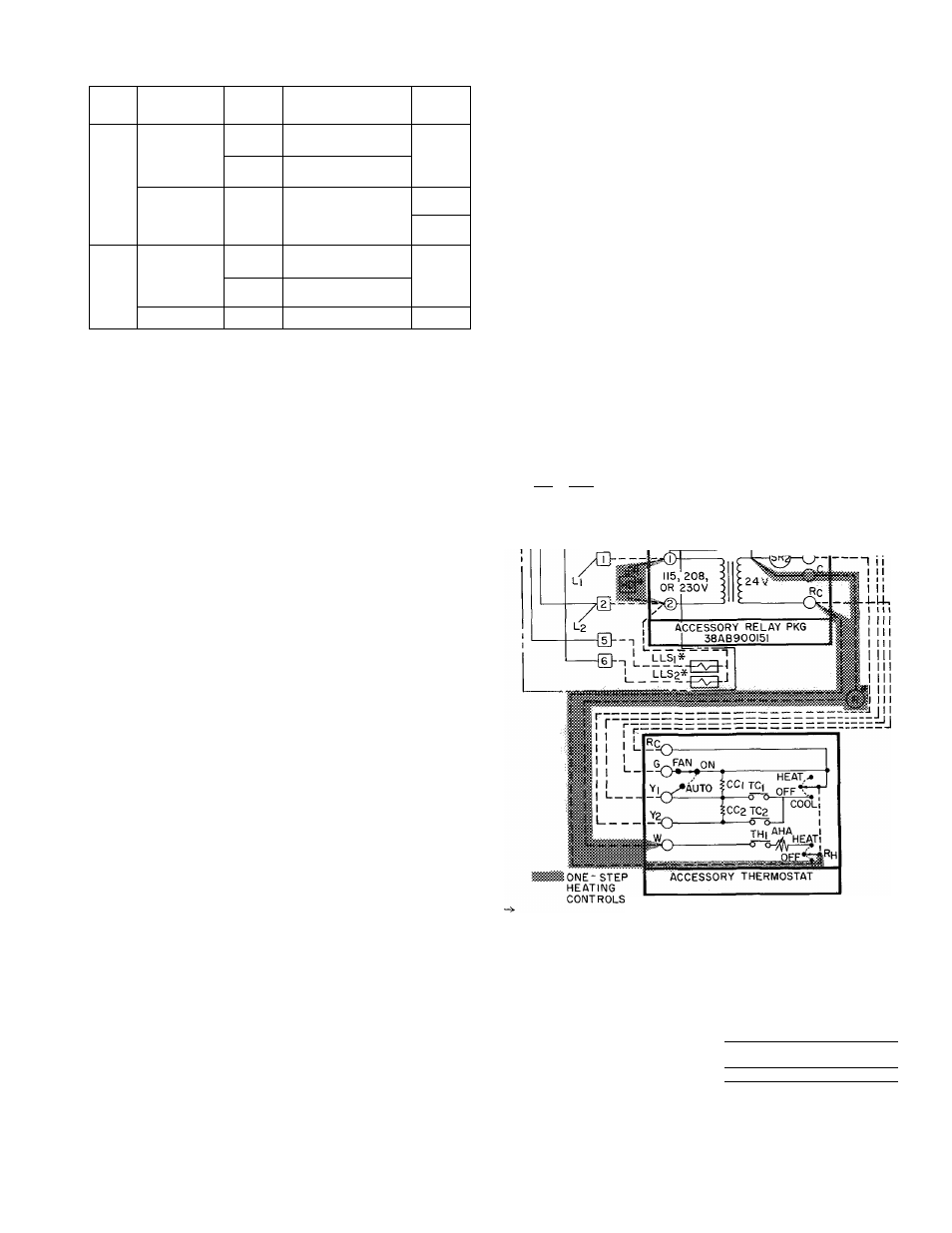

J TC2* ------------ E-------------------------------- --"fea-- TWO STEP COOLING 38AB054, 064 AND 084 , J LEGEND CR — Control Relay TC — Thermostat, Cooling LLS — Liquid Line Solenoid ---------Field Wiring TB — Terminal Board (at unit) *Field Supplied Fig. 10 — Control Circuit Wiring with Line Voltage (115, 208- or 230-volt) Thermostat LINE VOLTAGE REMOTE CONTROL - Install LOW-VOLTAGE REMOTE CONTROL - Install START-UP Preliminary Checks 1. Compressor oil level must be visible at sight glass in each compressor crankcase. Add oil if 2. Each compressor must float freely on its mounting springs. 3. All internal wiring connections must be tight, and all barriers and covers must be in place. Toggle switches for units 38AB054.,064 and 084 4. Electrical power source must agree with unit nameplate rating. 5. All service valves must be open. air stream under fan no. 1. 7. Crankcase heater must be firmly locked into the compressor crankcase. Leak Test the entire refrigerant system by the Pressure Method described in the Carrier Standard Service Techniques Manual, Chapter 1, Section 1-6. Evacuate and Dehydrate the entire refrigerant system by either of the methods described in the 38AB,054,064. 0^ SDRl CR)-------------------- •SDRir^ L-ll]------ l-2i (i^ —@ k 3^- —-ii THERMOSTAT HHOTATOTZ SUBBASE HH93AZ080 LEGEND AHA — Adjustable Heat SR — Solenoid Relay Anticipator TB -- Terminal Board cc — Cooling Compensator TC — Thermostat, Cooling CR — Control Relay TH — Thermostat, Heating HD — Heating Device — Factory Wired IFR IMS — Indoor Fan Relay -- ■ - Field Wired LLS — Liquid Line Solenoid n 1 Terminal Board Conn. R — Relay (Accessory) at Unit SDR — Solenoid Dropping Relay *Field Supplied Fig. 11 — Control Circuit Wiring with 24-Volt Accessories (38AB Units Only) 772

field-supplied line voltage thermostat(s) as shown

in Fig. 10 for two-step cooling. Wire liquid line

solenoid as shown.

field-supplied accessories as shown in Fig. 11 or

Fig. 12 for either two-step cooling or two-step

cooling, one-step heating. Wire liquid line solenoids

as shown.

necessary.

must be in “On” position.

6. Fan cycling thermostat sensing bulb must be in

Use R-22 at approximately 25 psig backed up with

an inert gas to a total pressure not to exceed 245

psig.

Carrier Standard Service Techniques Manual,

Chapter 1, Section 1-7.

— Indoor Motor Starter