S&s ‘d’ c, Read tuning instructions, Arburetors – Zipper's Performance G/D Carbs User Manual

Page 4

F

oR

s&s ‘d’

c

aRbuRetoRs

GENERAL INSTRUCTIONS

ThunderTech Products - 6655-A Amberton Drive - Elkridge, MD - 21075 - PH: (410)579-2929 - Fax: (410)579-2835

A.

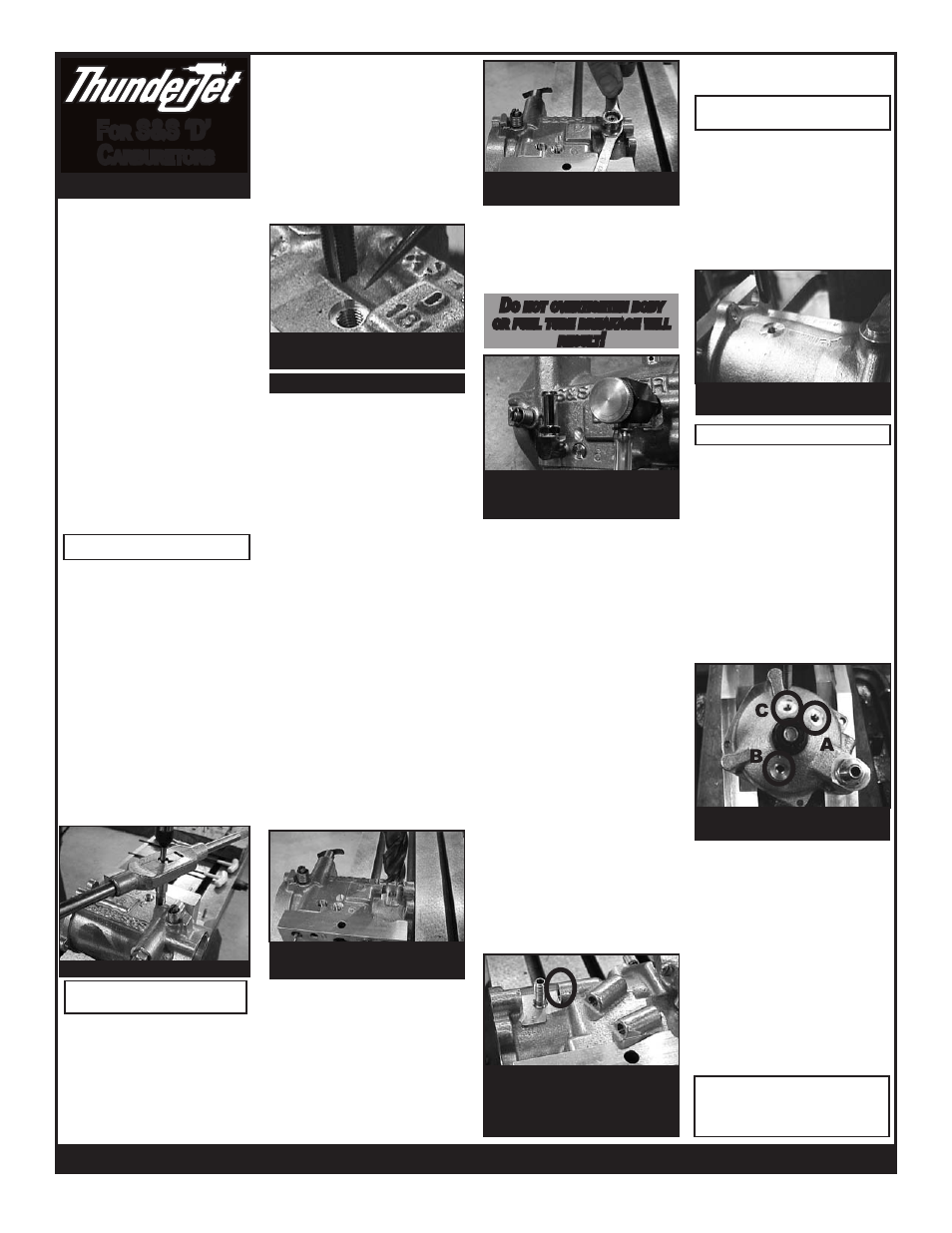

Tapping bowl vent for fitting

EXTERNAL FLOAT BOWL VENT

ADJUSTABLE AIR BLEED

CIRCUIT

If you do not have the facilities to properly

install this fuel module, professional

installation is available from Zipper’s.

High volume shops may want to invest in

our ThunderJet installation fixture (shown

in the photos p/n 713-910) which securely

holds the carb body and float bowl at the

correct positions for machining. Use with a

mill when installing ThunderJets in all S&S

model E/G/B/D carbs. Read all instructions

fully and carefully before proceeding any

further.

Loosen drain plug and remove float bowl

and manifold. Install two (2) studs in carb

manifold bosses; use these to center

carb in milling machine vise. Be careful

not to over tighten carb in vise. The first

two steps are recommended to further

enhance your carb’s performance along

with the installation of your ThunderJet.

1. Pressure in the float bowl is stabilized

with the addition of this external bowl vent.

Locate the new vent hole in the rear of the

carb wall .438” above bowl gasket surface

and 1.906” from the manifold flange of the

carb. Open hole with a small center drill

then plunge a 5/16” end mill to a depth of

.562” below the raised surface. Use a ½”

countersink to chamfer the raised surface

to help start the tapping process. Chamfer

only slightly not touching the lower level

surface. Tap with 1/8” NPT tap. Install

1/8” NPT street elbow and 1/8” NPT x 3/8”

hose nipple using a suitable thread sealer.

The hose nipple should be positioned

pointing up.

Air bleed passage drilled & tapped

for jet.

Fuel tube hole drilled/tapped, area

relieved for ThunderJet

THUNDERJET INSTALLATION

2. Earlier versions of “D” carbs are

manufactured with a fixed size air bleed

passage (current “D” models are now

machined for adjustable air bleed jets).

This modification will allow the tuner to

adjust the main jet air bleed size for more

control over the main jet circuit signal

NOTE: On “D” applications using only (1)

ThunderJet, the ThunderJet mounts on the

side of the carb facing the rear of the bike

(9:00 position). If using (2) ThunderJets fol-

low all instructions below and mount one

each in the 9:00 and 3:00 positions.

timing and fuel volume. Locate the fixed

air bleed hole and bore with ¼” drill until

you reach the cross drill in carb (DO NOT

GO PAST CROSS DRILL!!). Spot face the

area with 1/2” end mill for mating surface

of jet. Use 5/16-24 starter tap in hole and

remove to use a 5/16” bottom tap to finish

job. Original air bleed size is .042” and the

suggested range is .054-.072”. Use S&S

main jets for this.

9:00 POSITION

3. Drill and tap hole .750” from the end

of the carb throat, offset slightly above the

throttle butterfly shaft. Use a letter ‘i’ (.272”)

drill and tap 5/16”-24 thread. You will be

drilling through the middle of the original

float bowl vent passage; this is OK, it will not

affect performance or operation of the carb.

4. You then need to relieve the area

around the hole you just threaded for

air bleed spacer clearance. This is best

accomplished on a vertical mill with a 3/4”

end mill. With the cutter starting near the

bowl area, mill toward the top of the carb,

removing material at least ¼” above the

centerline of the fuel tube hole. Use care

not to break into the enrichener air passage

located above the hole. Leave .170-.185” of

carb wall for the short threaded portion of

the fuel delivery tube.

Double-nut and tighten fuel tube

in place

D

o

noT

oveRTighTen

boDy

oR

fuel

Tube

bReakage

will

ResulT

!

ThunderJet body (nipple down),

bowl cent & air bleed jet in place.

5.Install the fuel delivery tube from the

inside of the carburetor throat out. Double

nut the delivery tube using (2) ¼”-28 jam

nuts and carefully lock into carb throat

(DO NOT OVERTIGHTEN). Remove jam

nuts (not needed after this step).

6. Install air correction spacer, o-ring, and

ThunderJet with fuel nipple facing down

towards float bowl. Trim small opening

side of air correction spacer, if needed,

to achieve a hand tight location 1/6 of a

turn from permanent location and finish

tightening with wrench. (.006” trim = 1/6

turn).

3:00 POSITION

(Part 2 of twin T-Jet installation)

7. Drill and tap hole .950” from the end

of the carb throat, offset slightly above the

throttle butterfly shaft (letter ‘i’ (.272”) drill

and 5/16”-24 tap).

8. You then need to relieve the area around

the hole you just threaded for air bleed spacer

clearance. This is best accomplished on a

vertical mill with a 3/4” end mill, on center

of your threaded hole. Be certain to leave

.170-.185” of carb wall for the short threaded

portion of the fuel delivery tube. (Some D

carbs are equipped with dual float bowl vent

passages (forward and rear of carb throat);

you will be cutting through the forward vent

passage if equipped. This passage must

then be plugged, as its location will subject

the passage to positive air pressure at

speed, resulting in fluctuating pressure in

the float bowl, adversely affecting jetting.

Drill the passage past the ThunderJet

mounting area and tap it 5/16”, 3/8” deep

and plug it with a set screw. The external

vent described in step 1 must be performed

to replace this original vent.)

Hole A (9:00 position), B (3:00),

C (12:00)

13. ReaD Tuning

insTRuCTions

FOAT BOWL

PRO-STOCK OPTION

(12 O’Clock Position)

Spot faced, drilled/tapped for 3rd

T-Jet (Pro-Stock option)

fuel tube hole drilled/tapped,

area relieved for T-Jet, fuel tube

installed. Circle shows where vent

passage should be plugged

9. Follow steps 5, 6 & 7 from the 9:00

segment.

If a third ThunderJet is desired, drill, tap

(letter ‘i’ (.272”) drill and 5/16”-24 tap) and

spot face TOP center of carb 1.200” from air

cleaner backing plate surface, leaving .170-

.185” wall thickness for the short threaded

portion of the fuel delivery tube. Follow

steps 5, 6 & 7 from the 9:00 segment. Point

hose nipple towards rear of the bike and

slightly inward.

10. Clamp bowl to mill table at 35 degree

angle. See photo for bowl nipple location(s).

At the bottom of float bowl, beside drain,

drill a #3 hole and tap ¼”-28. Spot face the

area around the hole to give a flat surface

for the o-ring to seal against and reduce

thickness enough to allow the nut to attach

on the inside of the bowl. Install fuel nipple

and o-ring then secure inside bowl with nut

provided (no washer). Stake threads with a

punch to lock nut in place (make sure this

device does not interfere with float action or

movement). Repeat for multiple bowl nipple

locations.

12. Clean all carb parts; reassemble

and install fuel line with clamps provided

(trim fuel line if needed). Install on engine.

Install fuel line, turn fuel valve on and check

for leaks before starting engine!!