S&s ‘g’ c, Read tuning instructions – Zipper's Performance G/D Carbs User Manual

Page 3

ThunderTech Products - 6655-A Amberton Drive - Elkridge, MD - 21075 - PH: (410)579-2929 - Fax: (410)579-2835

F

oR

s&s ‘g’

c

aRbuRetoRs

GENERAL INSTRUCTIONS

F

oR

s&s ‘g’

c

aRbuRetoRs

READ INSTRUCTIONS FIRST!

Please read all instructions

fully and carefully before

proceeding.

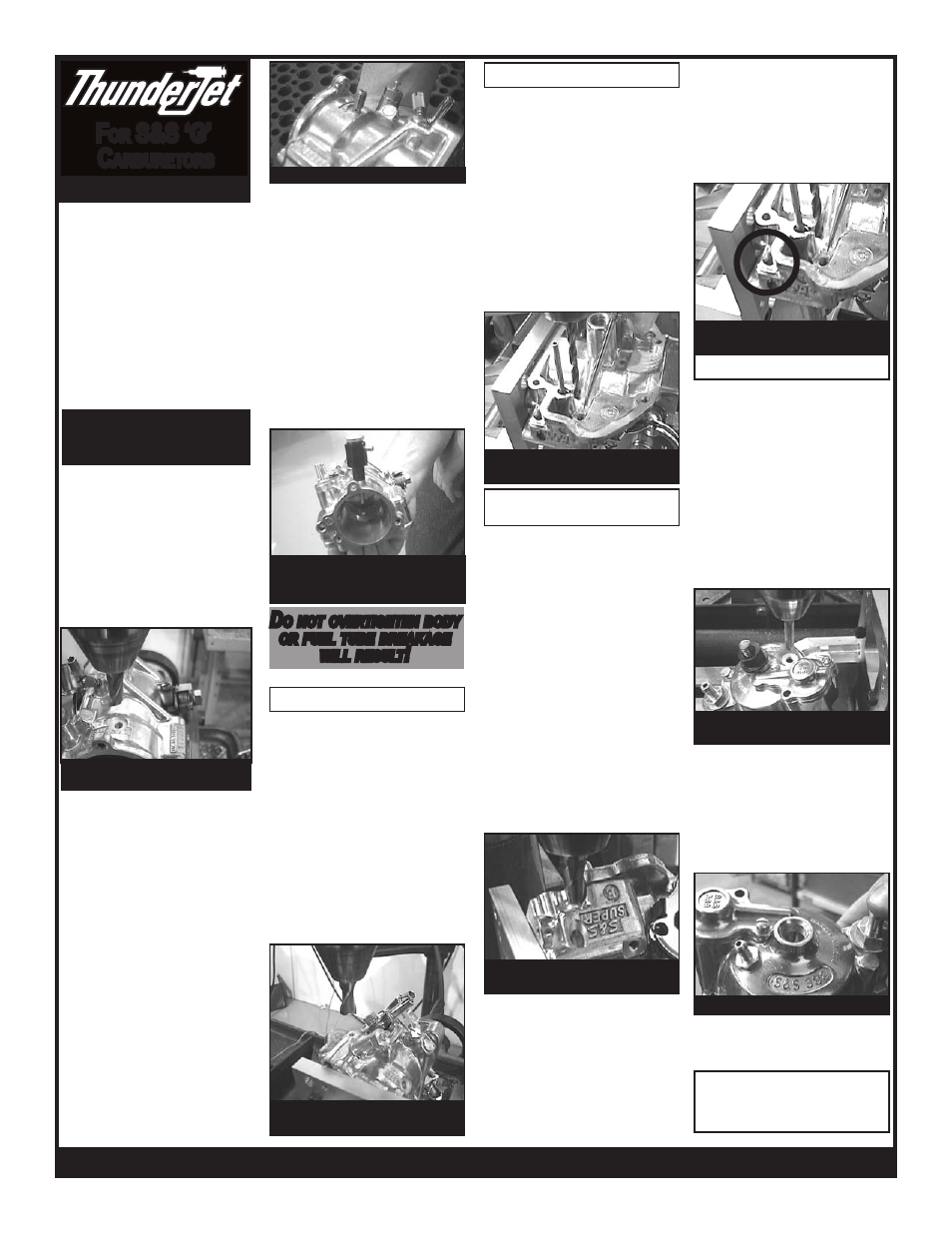

Drilled, tapped and spot faced for

fuel delivery tube.

Body and the air correction spacer

installed, nipple facing front of

bike.

Drilled, tapped, spot faced for

adjustable air bleed jet.

External bowl vent machined in

body.

If you do not have facilities available

to properly install this module,

professional installation is available

from Zipper’s. High volume shops

may want to invest in our ThunderJet

installation fixture (shown in the

photos, p/n 713-910).

This securely holds the Carb body

and float bowl at the correct positions

for machining. For use with a mill

when installing ThunderJets in all

S&S model E/G/B/D carbs.

1. Loosen the drain nut and remove

your float bowl from the Carb.

Remove emulsion tube with main

jet from Carb body and remove the

accelerator pump rod, rubber bellows

and discharge o-ring. Looking into

Carb throat, turn Carb counter-

clockwise at approximately an 11

degree angle and clamp in vice.

2. The location for drilling, tapping

and spot facing the fuel tube hole is

.950” from the air cleaner mounting

surface; use the upper left corner of

the “T” in the word “SHORTY” for

locating the other axis. Drill a letter “I”

hole, tap 5/16-24. Using 1/2” end mill,

counterbore hole until you maintain a

3/16” (.187) wall thickness (photo 1).

4. Locate air bleed passage plug

above S&S nameplate on throttle

spool side of Carb. Clamp Carb body

at approximately a 45 degree angle.

Center a 5/16” end mill over the plug

and spot face lightly to flatten and

align. Use a center drill to start and

then drill the plug with a #19 drill bit and

tap 5mm x .8mm for air bleed (photo

4). Install air bleed jet (same type jet

used in ThunderJet). Jet sizes range

from 130-170 for most applications

(see chart).

3. Remove jam nuts (no longer

needed). Install the air correction

spacer (small opening out), o-ring and

ThunderJet body on to Carb. Fuel line

nipple should point to front of bike and

slightly toward the air filter for hose

routing (photo 3). Trim small opening

side of air correction spacer, if needed,

to achieve a hand tight location 1/6 of a

turn from permanent location and finish

tightening with wrench. (.006” trim =

1/6 turn). DO NOT OVERTIGHTEN

BODY OR FUEL TUBE BREAKAGE

WILL RESULT!!

5. Clamp Carb in vise upside down.

Locate original internal air bleed hole

(photo 5) to be blocked off. (’04 and

earlier) Carefully drill this passage with

a #21 (.159”) drill bit until you break

into cross passage in Carb body. Tap

hole with a 10-32 tap, blow passage

out with compressed air, then plug with

supplied 10-32 slotted screw. (’05 and

later) These carbs come with a main

jet style air bleed jet; remove the jet

and plug the hole with the supplied

5/16-24 set screw.

Adjustable Air Bleed

Original air bleed passage tapped

for block-off screw.

Fuel delivery tube installed.

Original Air Bleed Blocking

6. We have found additional

performance and increased fuel

pressure stability in the float bowl by

relocating and modifying the float

bowl vent passage. Clamp body

upside down at a 45 degree angle.

Remove the existing 5/16” bowl vent

plug (photo 6). Using a small center

drill or wiggler, locate the center of the

hole where plug was removed. Mark

a spot 7/16” from the casting surface

where vent plug was removed, toward

top of Carb. Using a small center

drill, break through to existing vent

passage. Finish hole using a 5/16”

2-flute end mill at this angle. Cut only

deep enough to enter existing vent

cross drill!

In extreme high velocity applications,

we recommend plugging the original

vent passage at the air cleaner backing

plate surface (tap opening 5/16-24).

Use the 5/16”-24 plug removed from

the vent passage to plug the original

opening, as extreme airflow can create

a vacuum that may draw fuel through

(Optional) Bowl Vent

Relocation

3. Install the fuel delivery tube

from the inside of the Carb throat

out (photo 2). Using (2) ¼”-28 jam

nuts, double-nut the fuel delivery

tube outside of the Carb throat and

carefully lock tube into Carb throat

until all or most of the air bleed

segment is exposed.

D

o

noT

oveRTighTen

boDy

oR

fuel

Tube

bReakage

will

ResulT

!

Remove bowl vent passage

plug.

Bowl drilled, tapped and spot

faced for bowl fitting

Bowl fitting installed

7. Remove float from bowl. Set bowl

at a 20 degree angle on sine plate.

Drill a #3 hole between bowl drain plug

and accelerator pump housing and tap

with ¼”-28 tap. Spot face hole center

(kiss) just enough to give a flat surface

for o-ring to seal against (photo 8).

Install fuel nipple and o-ring, secure

inside bowl with lock washer and nut

provided (photo 9). Make sure this

device does not interfere with float

action.

8. Thoroughly clean Carb, check low

speed and main jet sizes for engine

compatibility (see tuning tips), re-

assemble Carb and install fuel line with

clamps provided. Fuel hose is routed

to front of bike. See tuning instruction

page for jetting instructions.

Float Bowl

9. ReaD Tuning

insTRuCTions

the vent and uncontrollably richen

the mixture. Install the plug just deep

enough to be slightly below the air filter

mounting surface, and use Loctite. If

you choose not to do this modification,

at least remove the vent plug and

discard it.