Winco ECV2512-3 User Manual

Page 5

Page 3

60706-130

7150-01

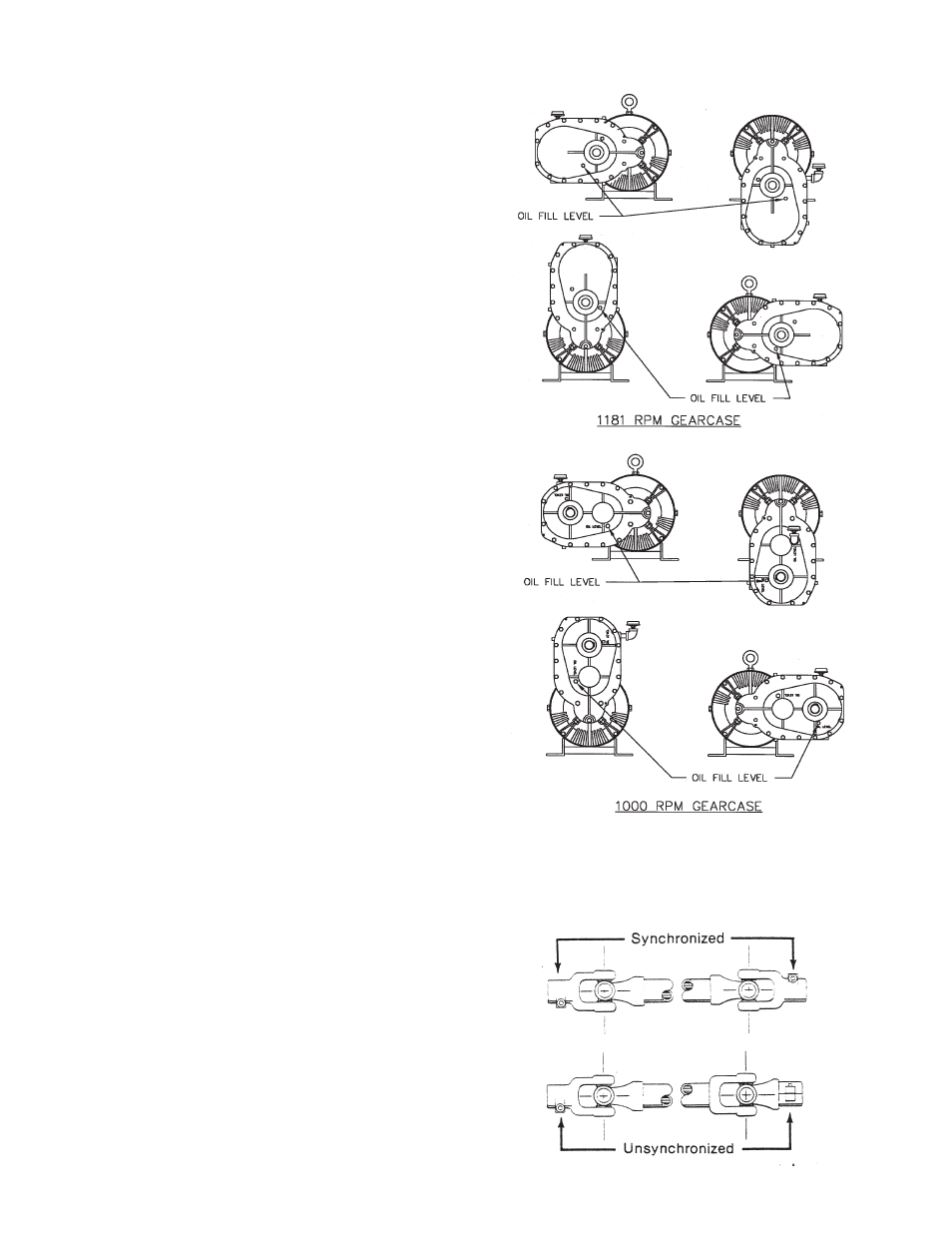

Make sure the drive shaft (tumbling bar) is assembled with

its universal joint knuckles “synchronized,” as illustrated in. If

knuckles are not synchronized, the bar will chatter when

rotating, which will cause the generator output voltage to

flicker.

2. Location. Locate as close to electrical service as pos-

sible. This will reduce the cost of electrical and minimize

the losses in the power conductors. Position the unit to

keep clear of the drive line and exhaust runs.

3. Mounting Support. Frame loading, frame type and

strength should be taken into consideration when

installing an emergency rescue generator under a

truck.

4. Moisture and Dirt. Protection from adverse weather

conditions and road spray must be provided without

restricting adequate ventilation for cooling. All

electrical equipment should be protected from

excessive moisture. Failure to do so will result in

deterioration of the insulation and will result in short

circuits and grounds. Foreign materials such as

dust, sand, tint and abrasive materials have a

tendency to cause excessive wear, particularly the

brushes. It is important that the unit be installed in a

reasonably clean location for best service life. Careful

planning will eliminate costly rework.

5. Heat and Cold. All generators radiate considerable heat

when they are running. In addition, these units are

generally mounted in a somewhat restricted location

which precludes natural cooling. Allow space for cool-

ing air to sweep across the generator shell. It is impor-

tant that the temperature of the ambient air around the

unit not exceed 105 degrees Fahrenheit while operat-

ing. Additional cooling louvers or fans may be neces-

sary if adequate cooling flow is not naturally provided.

B. MOUNTING THE GENERATOR SYSTEM

The generator should be bolted solid to a heavy steel

cross channel or plate. It is recommended that the

generator be mounted on a steel sub-frame which

facilitates easy removal of the generator for better service

access to the chassis or for generator repair.

Shock mounting the generator or mounting frame is

generally not recommended do to possible harmonic

vibration, drive misalignment and mounting stress.

C. VENTILATION OF GENERATOR

This is an air cooled generator. This unit is equipped

with a suction fan to cool the armature and field coils.

Therefore it will be necessary to insure that the hot air

discharge plume gets out of the mounting area.

D. DRIVE LINE AND LUBRICATION

Check gear case oil level. Case should be filled with oil

to plug marked “OIL LEVEL.” Fill or remove oil as re-

quired.

NOTE: EITHER TOO LITTLE OR TOO MUCH OIL CAN

HARM THE EQUIPMENT.

See “Lubrication” portion of Maintenance for oil specifica-

tions.