Operating the unit – Winco RP25/A User Manual

Page 10

Page 8

60706-201

8190-00

switch be installed, remove the jumper and install a

normally closed emergency stop switch between the two

terminals. When the emergency stop switch is opened

the generator will instantly shut down, requiring the

switch to be reclosed before the generator can be

restarted.

2. Remote start contact connections for starting the

unit from a remote location. This can be either an

automatic transfer switch or just a remote switch in a job

trailer. This feature requires a relay closure between the

two connections on the terminal block to put the unit into

an auto-start mode. This Auto start mode does have

both a start delay and a cooldown delay built into the

DGC-2020. In addition the DGC-2020 will ensure the

unit is no longer carrying any load before it shuts the

engine down even after the remote start contacts have

been opened.

M - FULL POWER OUTPUT TERMINAL BLOCK.

The full power terminal block is capable of handling full

generator output at any of the selected voltages. Be very

careful when using 240 volt three phase that you properly

account for the wild leg (208 Volt) coming from the

generator. This unit has it in the G3 position. For

single phase 120/240 use G1 and G3, the third leg G2 is

not powered or used. Lugs will handle up to 2/0 wire.

Torque lugs to 150 in. lbs. using #1 & #2 wire and 180

in. lbs. for 1/0 & 2/0 wire.

N - WIRE ENTRANCE HOLES. These hole have been

specifically provided for you to route your full power leads

through to the output lugs. The routing holes were

provided to insure that no small child or curious adult

could reach up inside and come in contact with the main

output lugs with the unit running.

DANGER: PERSONAL INJURY

This unit will start as soon as the door is closed if the

start switch is in the run position. Do not use the switch

on this door to shutdown a unit to connect to the full load

terminal block , this is a safety switch only.

OPERATING THE UNIT

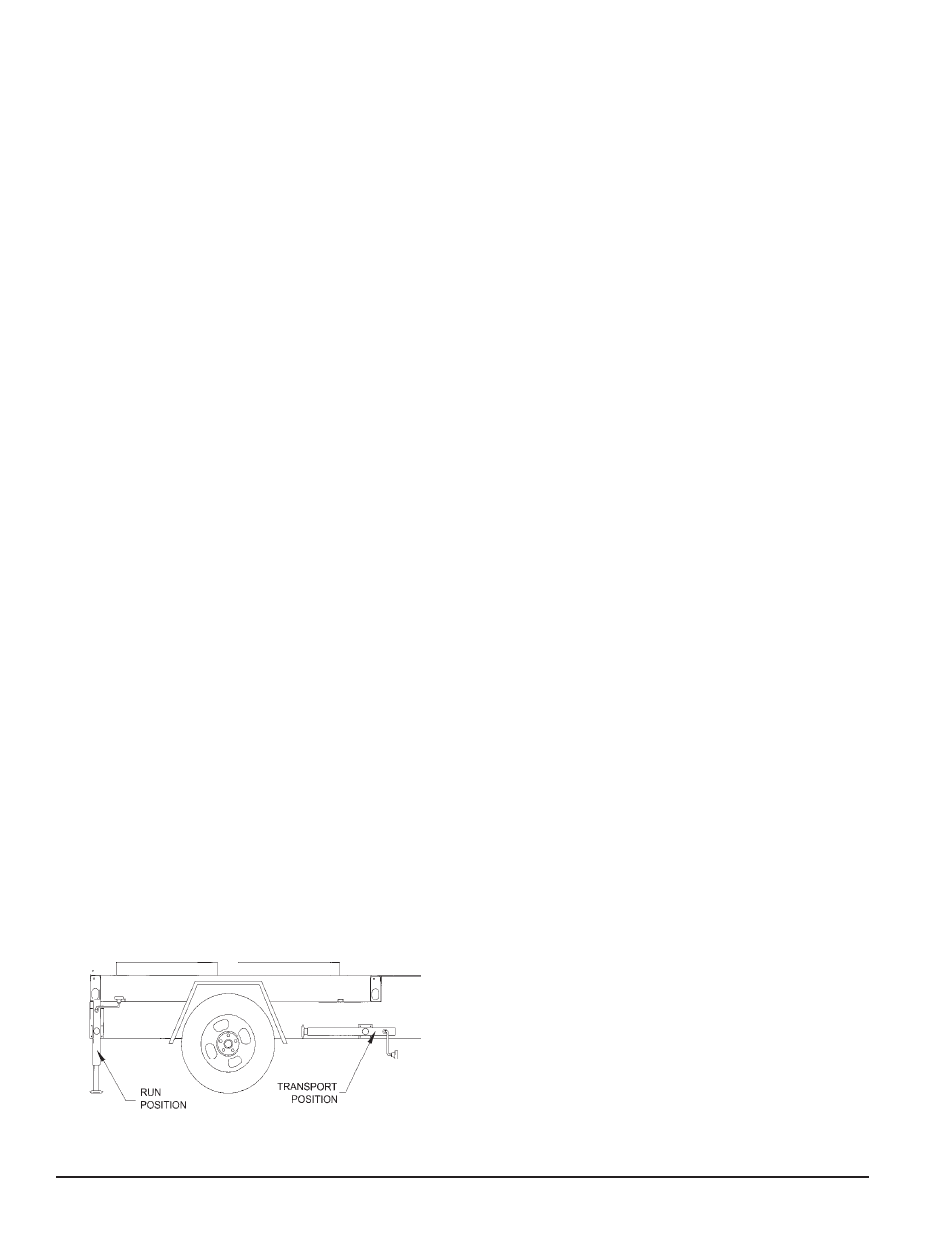

A. SETTING THE JACKS

1. Move the two rear jacks from the transport position to

the run position.

2. Rotate the front jack from the transport position to the

run position.

3. Level the unit using the three jacks before proceeding.

WARNING - POTENTIAL EQUIPMENT DAMAGE

Besure to return the jacks to the transport position before

trying to move the unit. If you don't the jacks maybe

damaged, rendering them useless.

B. SELECTING THE CORRECT VOLTAGE

A variety of voltages are available from the four position

selector switch. The four basic connection patterns are,

Delta (120/240), Low or Parallel WYE (120/208), High

WYE (277/480) and Single phase 120/240.

Before starting this unit be sure you have the selector

switch set for the right voltage. You must depress the

safety switch below the selector switch to change the

position of the voltage selector switch. If the unit is

running depressing this switch will kill the engine genera-

tor set.

If you have any doubts as to the voltage in your area

compare your incoming power or load name plates to the

voltage table below.

1.

120/240 Single Phase* This configuration will

produce the following line-to-line and line-to-neutral

voltage. In this selector switch position, all of the recep-

tacles on the front panel are powered.

G1 - G3 240 Volts single phase

G1 - N 120 Volts

G2 - N Dead

G3 - N 120 Volts

2.

120/240 Three Phase* (Delta/Series configuration) -

This configuration will produce the following line-to-line

and line-to-neutral voltage. In this selector switch position,

all of the receptacles on the front panel are powered.

G1 - G2 - G3 240 Volts three phase

G1 - G2 240 Volts single phase

G2 - G3 240 Volts single phase

G1 - G3 240 Volts single phase

G1 - N 120 Volts

G2 - N 208 Volts

G3 - N 120 Volts