Winco 75FPTOC-17 User Manual

Page 8

Page 6

60706-125

7315-000

energized by the generator. Make sure the connections are

correct and are tight.

8. Make sure all loads are turned off. Do not start the genera-

tor under load.

GENERATOR STARTING PROCEDURE

1. With the power take-off drive disengaged, start the engine

which will drive the generator. Run the engine long enough to

warm it up before proceeding, so that it will run smoothly and

achieve full power under generator load.

2. With engine idling, engage the power take-off drive.

3. Watch the voltmeter on the generator and slowly increase

engine speed until the output reaches approximately 260 volts

(in green portion of voltmeter scale). For 208 volt generators

the output should reach 215 to 220 volts.

4. With engine and generator running smoothly, switch on the

electrical load while watching the voltmeter.

NOTE: Equipment Damage

If the load includes motors turn them on one at a time, highest

starting current motor first, next highest second, etc.

Readjust engine throttle to keep generator output under load

at 240V or 208 depending on the generator (in green portion

of voltmeter scale). If engine is equipped with speed governor,

it may automatically readjust the throttle as the load changes

and keep the generator output at the proper level. However,

some governors are not sensitive enough to maintain proper

output under changing load, and in such cases the throttle will

have to be manually readjusted .

GENERATOR SHUTDOWN PROCEDURE

1. Switch off electrical load.

2. Reduce speed of engine driving generator to idle.

3. Disengage power take-off drive, and allow generator to

coast to a stop.

WARNING: Personal Injury

Never try to manually stop the generator. Always let it coast

until it stops.

5. Shut off the engine.

4. Disconnect drive shaft (tumbling bar)

power take-off end first, then generator end.

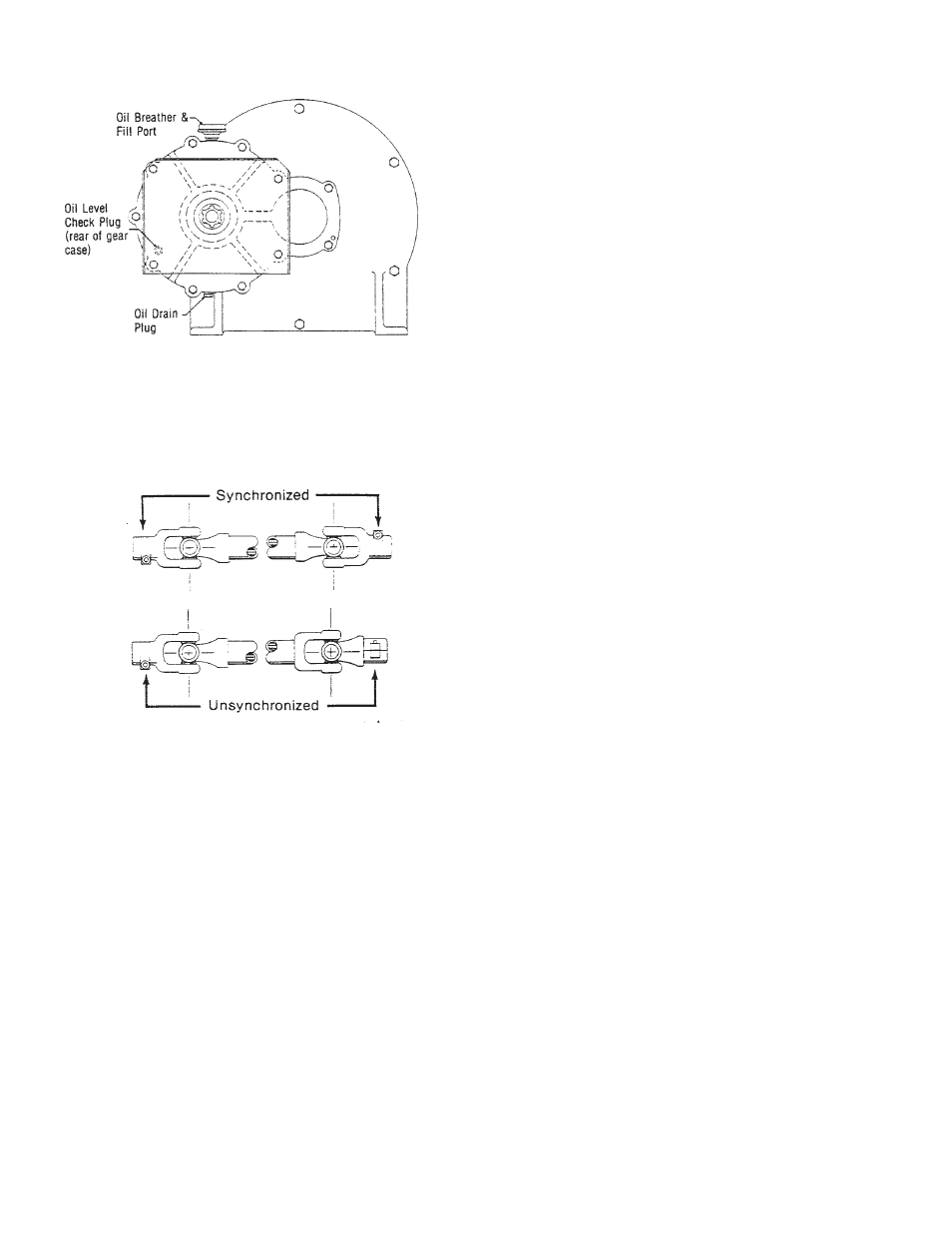

Figure 6

3. Make sure the drive shaft (tumbling bar) is assembled with

its universal joint knuckles “synchronized,” as illustrated in

Figure 7. If knuckles are not synchronized, the bar will chatter

when rotating, which will cause the generator output voltage to

flicker.

DANGER: Personal Injury

POWER TAKE-OFF MUST BE DISENGAGED AT THIS TIME.

4. Couple the tractor to the generator with the drive shaft

(tumbling bar). Couple the tumbling bar to the generator input

shaft first, then to the power take-off shaft. Check alignment,

tractor, power take-off shaft (tumbling bar), and generator input

shaft should form a straight (or nearly straight) line, with less

than 15° misalignment between the shafts. Misalignment will

cause generator output voltage to flicker.

CAUTION:

Make sure that all tumbling bar lock pins are engaged and

that all safety shields are in place before operating the PTO

generator.

5. Make sure no binding exists in generator or gear box. If

binding is found, locate the cause and correct it before

proceeding.

6. Make sure that the electrical loads to be driven by the

generator will not draw more current than the ratings of the

generator receptacle or cord set which will supply the current.

7. Check all electrical connections in the system to be

Figure 7