Unpacking, Assembly – Winco 75FPTOC-17 User Manual

Page 4

Page 2

60706-125

7315-000

Description

The WINCO PTO drive generator will provide, depending on

the unit purchased, 120/240V single phase, 120/240V three

phase or 120/208 three phase 60Hz electrical service when

direct-driven. Tractor or vehicle power take-off shafts, can be

used for driving these generators.

NOTE: The prime mover which drives the generator must be

capable of delivering approximately 2 HP per 1000 watts

output from the generator. Observe input RPM specifications.

The generator may be foundation mounted for use as standby

power source, or trailer mounted, and used as portable

electrical power sources for areas where commercial power

is not readily available, such as out buildings.

This generator includes a load sensing transformer which

provides extra motor starting power, a color coded voltmeter to

warn against high or low voltage, three output power recep-

tacles, an overload protection circuit, and an electronic

excitation circuit. To reduce maintenance problems, the

coupling between the generator input shaft and rotor consists

of precision helical gearing rather than a chain link drive. The

input shaft is splined, and is 1-3/8 in diameter.

The factory thoroughly tests each of these generators before

shipment. All are continuous duty rated.

IMPORTANT: THE MANUFACTURER STRONGLY RECOM-

MENDS RUNNING THE GENERATOR UNDER LOAD AT

LEAST ONCE A MONTH IN ORDER TO EVAPORATE ANY

ACCUMULATED MOISTURE CONDENSATION

UNPACKING

CAUTION: Equipment Damage

DO NOT invert generator during unpacking. The Gearcase

contains oil which will leak out if inverted during unpacking.

Unpack the generator as follows:

1. Remove the carton.

2. Examine the unit for damage.

3. Find the small subpack carton packed in the large carton.

Be careful not to throw away the subpack carton with the large

carton.

4. Open the subpack carton and make sure it contains:

a. Generator instruction manual

b. Load disconnect plug (disassembled, in bag)

5. Remove the four bolts which hold down the generator feet

to the pallet.

6. Lift the generator from the pallet by means of the lifting eye

on the top of the generator.

7. Inspect the generator carefully for freight loss or damage. If

loss or damage is noted at time of delivery, require that the

person making the delivery make note of the loss or damage

on the freight bill, or sign the consigner’s memo of the loss or

damage. Contact the carrier for claim procedures.

When loss or damage is noted after delivery, segregate the

damaged material, and contact the carrier for claim proce-

dures.

“Concealed damage” means damage to the contents of a

package which is not evident when the package is delivered

by the carrier, but which is discovered later. The carrier or

carriers are responsible for merchandise lost or damaged in

transit. The title to the goods rests with the consignee when

the goods are shipped FOB factory, and only the consignee

can legally file claims. Two years are allowed in which to file

suit after a claim is disallowed in writing by the carrier.

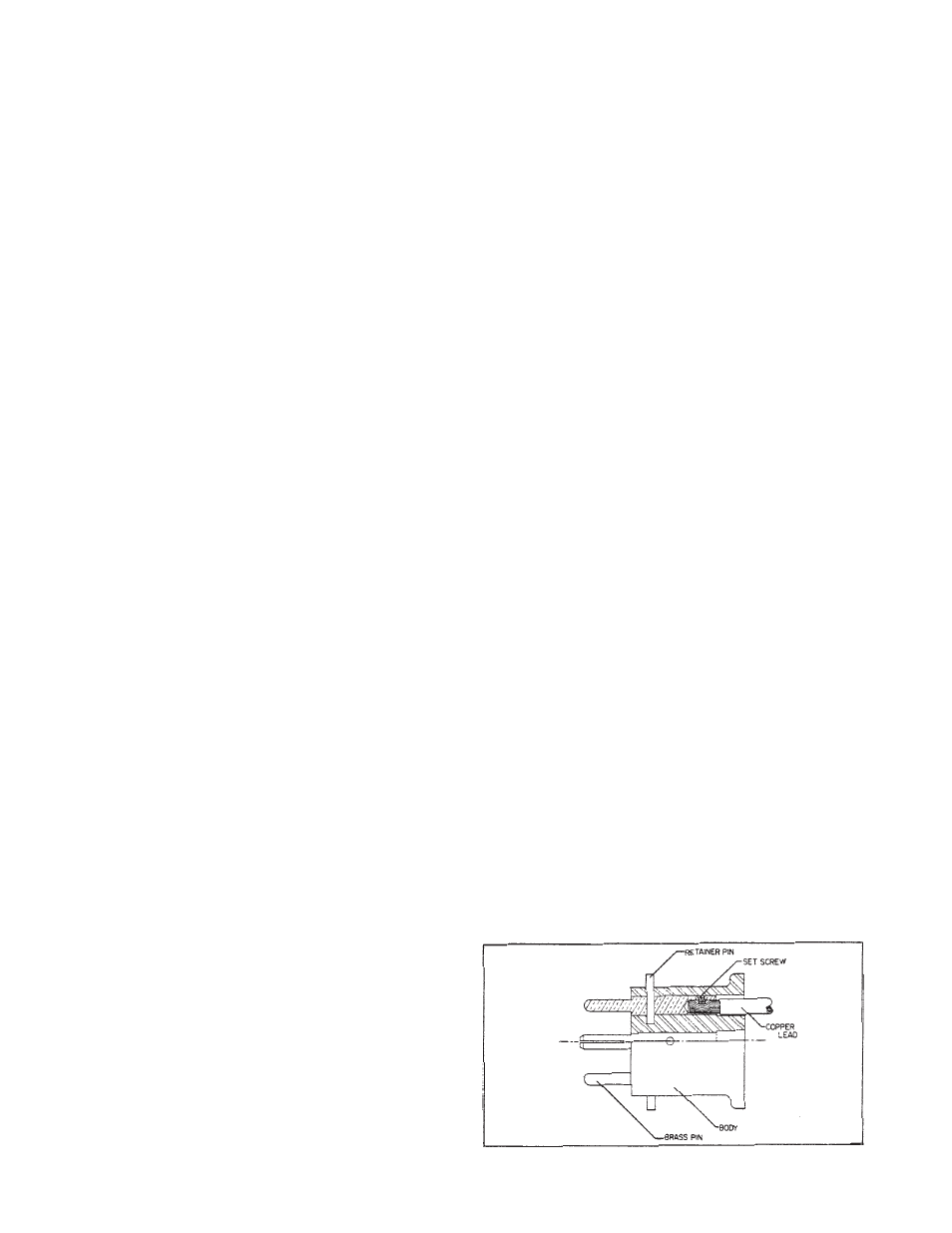

Assembly

The only assembly work required after unpacking the genera-

tor is to assemble and wire the load disconnect plug, which is

contained in a bag in the subpack carton packed in the

generator crate. The bag contains an instruction sheet, a plug

body, three or four brass pins (large pin for neutral line), and a

small envelope. The small envelope contains an allen

wrench, retainer pins, and set screws.

To wire the load disconnect plug, use the following type of

cable:

Generator

Size,

Model

AWG

Insulation

35PTOC-3

1

600V, THW

40PTOC-4

4

600V, Neoprene

45PTOC-17

4

600V, Neoprene

50PTOC-3

1

600V, THW

55PTOC-3

1

600V, THW

75PTOC-4

1

600V, THW

75PTOC-17

1

600V, THW

To assemble and wire the load disconnect plug,

proceed as follows (see Figure 1):

1. Cut cables to the required length.

2. Strip off insulation 7/8" back from one end of each cut-to-

length cables.

3. Start threading a set screw into each pin.

4. Insert the stripped end of one cable fully into one of the

brass pins, and tighten the set screw firmly to secure the

cable end in the pin.

Octopus Plug Assembly

Figure 1