Winco PSS65LS-*/B User Manual

Page 7

60706-144

Page 5

1017-10

Fuel Pressure Table

Single Regulator (L.P. Vapor only)

1

2

3

UNIT OFF

TANK PSI

7-11 in 7-11 in

4-6 oz 4-6 oz

STARTING

TANK PSI

7-11 in 7-11 in

4-6 oz 4-6 oz

NO LOAD

TANK PSI

7-11 in 7-11 in

4-6 oz 4-6 oz

FULL LOAD

TANK PSI

7-11 in 7-11 in

4-6 oz 4-6 oz

Two (2) Regulator System (L.P. Vapor only)

1

2

3

4

UNIT OFF

TANK PSI 10-15 lbs

7-11 in

7-11 in

4-6 oz

4-6oz

STARTING TANK PSI 10-15 lbs

7-11 in

7-11 in

4-6 oz

4-6 oz

NO LOAD

TANK PSI 10-15 lbs

7-11 in

7-11 in

4-6 oz

4-6 oz

FULL LOAD TANK PSI 10-15 lbs

7-11 in

7-11 in

4-6 oz

4-6 oz

Natural Gas

1

3

4

UNIT OFF

LINE PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

STARTING

LINE PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

NO LOAD

LINE PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

FULL LOAD

LINE PSI

7-11 in.

7-11 in

4-6 oz

4-6 oz

Notice the preceding tables give two (2) different units

of measuring fuel pressure. The first is with a pressure

gauge calibrated in ounces per square inch. The second

and most accurate is the use of a simple water manome-

ter. A manometer is calibrated in inches of water column.

LP LIQUID WITHDRAWAL SYSTEMS

When installing a unit equipped the LP liquid withdrawal

a primary regulator is not required on the supply tank.

The supply line is connected to a liquid withdrawal valve

on the supply tank and run directly to the fuellock strainer

mounted on the engine generator set. Normally a 3/8 inch

copper line is acceptable for this type of fuel installation.

You must be sure that the valve you have connected to on

the supply tank is in fact a liquid supply valve and has a

drop tube inside the tank that is pulling fuel from the bot-

tom of the supply tank. Before starting the unit you must

confirm that you have a good liquid supply at the unit. En-

gine generator sets equipped for liquid withdrawal will

not run properly when supplied with high pressure va-

por fuel.

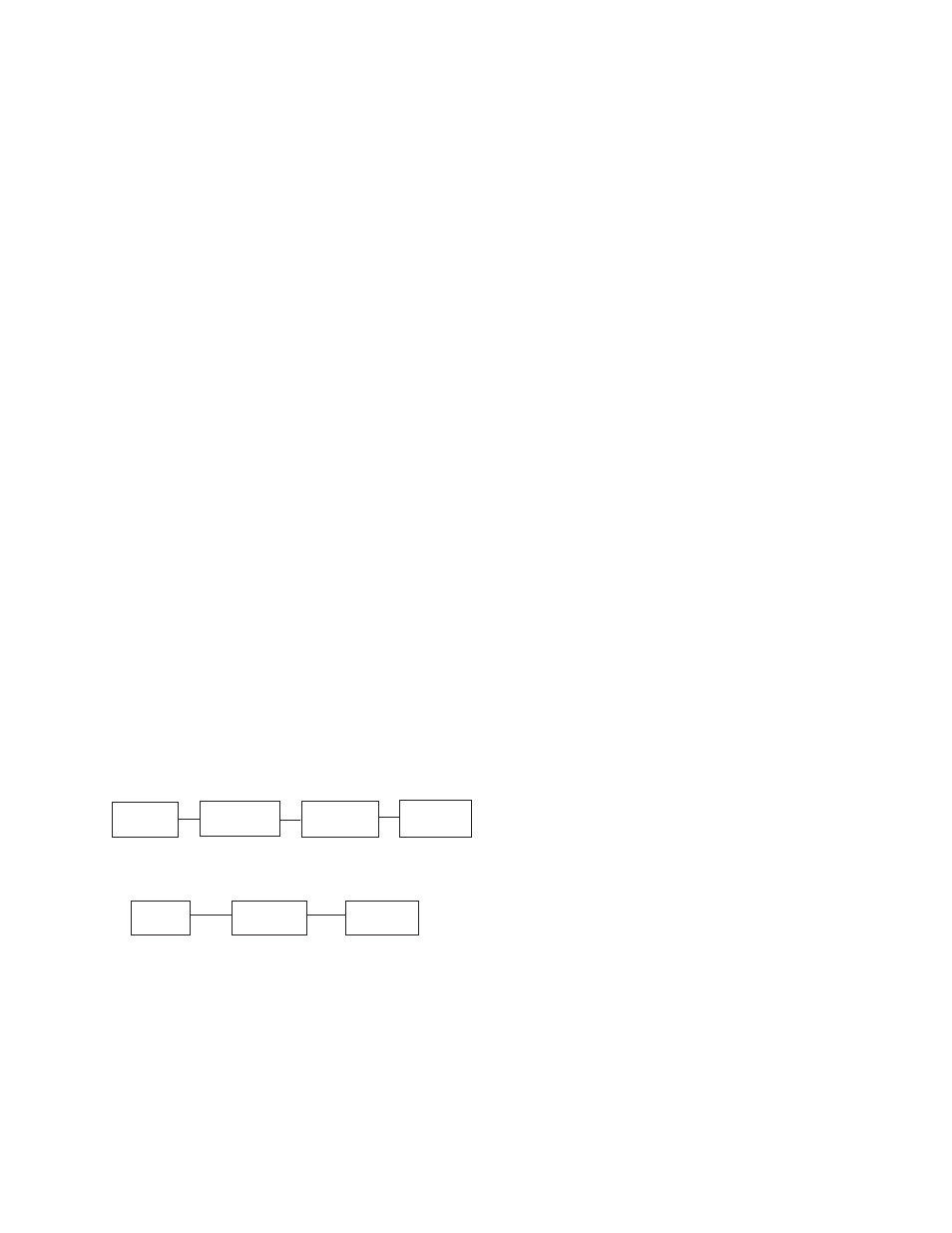

The following is a block diagram of a typical L/P Liquid

Withdrawal fuel system.

generally adequate for distances up to 300 feet from the

primary to the secondary regulator. (Consult your local

fuel supplier for your exact requirements). The appropriate

line size from the table below is then installed from the

second regulator to the generator set.

*************

***** WARNING ****

*************

PERSONAL DANGER - Do not use galvanized pipe in

fuel line runs. The galvanized coating can become eroded

and flake off, causing possible obstructions in the regulator

or fuel valve. The results could range from inoperative en-

gine start to hazardous fuel leaks.

Size of pipe normally required for generators operating

on NATURAL/LP gas.

up to 25 feet* over 25 feet*

PSS50000 1-1/4" pipe

Not recommended use

PSS65000 1-1/4" pipe a two regulator

system

* Allow an additional 3 feet for each standard elbow.

Do not use ‘street ells’ (restrictive)*

**** CAUTION ****

EQUIPMENT DAMAGE - Be careful when sealing gas

joints. Excessive sealing compound can be drawn into the

solenoid, regulator or carburetor causing an engine mal-

function.

FUEL PRESSURE (vapor system)

Correct fuel pressure cannot be stressed enough. The

most common cause for inoperative systems is an inade-

quate or incorrect fuel pressure. Performance of the en-

gine is in direct relation to the correctness of the fuel sys-

tem. Shown below is a block diagram of a typical L.P. or

N.G. Installation.

Supply

Primary

Secondary

Generator

Tank

Regulator

Regulator

Set

1 2

3

4

TWO (2) REGULATOR FUEL SYSTEM

Supply

Primary

Generator

Tank

Regulator

Set

1

2

4

SINGLE REGULATOR FUEL SYSTEM

Reference numbers 1 through 3 in the block diagrams

above are fuel lines supplied by customer.

Reference number 4 is the engine generator set.

Below is a table of the fuel pressure reading at each ref-

erence in the system.