Initial start up, 4 wheel dolly kit (optional), Oil alert system – Winco WL18000VE/N User Manual

Page 7: Basic operation

7

3110-00

60706-39

WARNING: PERSONAL INJURY

Lead acid batteries produce explosive hydro-

gen gas when charging. Keep sparks, flames, and

burning cigarettes away from the battery. Ventilate

the area when charging or using the battery in an

enclosed space. Lead acid batteries contain sulfuric

acid, which causes severe burns. If acid contacts

eyes, skin or clothing, flush well with water. For con-

tact with eyes, get immediate medical attention.

BATTERY CHARGING

Units equipped with electric start have a small fly-

wheel charger built into the engine flywheel assem-

bly for recharging the starting battery. This flywheel

charger generates a small AC current that passes

through a diode assembly to produce a DC charg-

ing current of about 1 to 3 AMPS. This circuit is not

designed to be used as a battery charging circuit to

recharge dead batteries.

4 WHEEL DOLLY KIT (OPTIONAL)

The WL18000 is available with an optional 4 wheel

dolly kit. The dolly kit comes with instructions and

parts list. After installing the dolly kit, file the instruc-

tions and parts list in the back of this manual for

future reference.

CAUTION: EQUIPMENT DAMAGE

This is a four wheel dolly kit be sure to chock the

wheels properly before operating the generator.

Failure to properly restrict unit movement will allow

the unit to move causing damage to the unit, drop

cords or loads.

OIL ALERT SYSTEM

This WINCO Industrial generator is equipped stan-

dard with low oil shutdown systems. The Briggs and

Stratton engine uses an oil pressure switch system.

This low oil warning system will automatically stop

the engine before the oil level reaches a critical dan-

ger point. This feature is designed to prevent costly

repairs and downtime.

CAUTION: EQUIPMENT DAMAGE

Allowing the engine to shutdown repeatedly on

low oil level may cause excessive wear which can be

cumulative.

INITIAL START UP

The throttle control on these generators is preset

and locked to operate at 3600 RPM (nominal) with

no load speed set at 3690 RPM. Only a trained

service technician should be allowed to adjust this

speed setting.

NOTICE: ENGINE START LOCKOUT

This unit will not start if it is low on oil. The lu-

bricating oil level must be at the

full mark before the

engine will start and run.

BASIC OPERATION

ELECTRIC STARTING

This engine is electric start only. The batteries must

be maintained in good condition to prevent hard

starting or damage to the engine mounted starter.

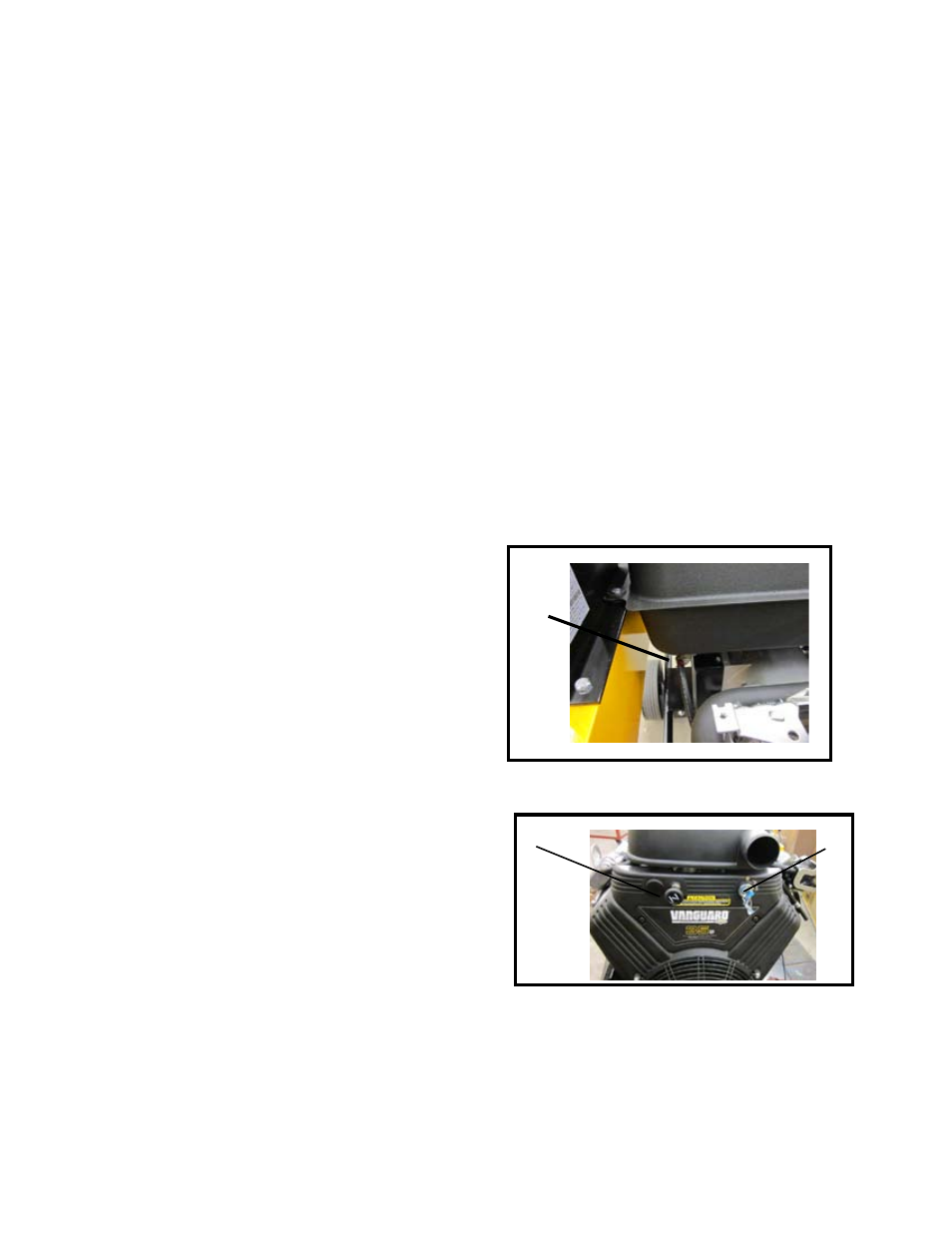

1. Check oil level, refill as needed

. Turn on the fuel supply. Ref “A”

3. Move the choke to the full “on” position. A warm

engine will require less choking than a cold

engine. Ref “B”

A

B

C