Initial start up, Oil alert system, Basic operation – Winco WT3000H/C User Manual

Page 7: Manual starting

7

277-00

60706-24

Never use gasoline that has been stored for an ex-

tended period of time as the fuel will lose its volatile

properties and you will be left with varnish residue.

The varnish like substance will clog the carburetor

and will not burn properly.

The use of fuel additives, such as STA-BIL, or an

equivalent will minimize the formation of fuel gum

deposits. If a unit has been out of operation for an

extended period of time, it is best to drain old fuel

from the engine and replace with fresh fuel before

attempting to start.

OIL ALERT SYSTEM

This WINCO Industrial generator is equipped with a

low oil shutdown system. This engine uses a float

switch mounted inside the engine. If the oil level

drops below a certain point the low oil module on the

engine will shut it down. This low oil warning system

will automatically stop the engine before the oil level

reaches a critical danger point. This feature is de-

signed to prevent costly repairs and downtime.

CAUTION: EQUIPMENT DAMAGE

Allowing the engine to shutdown repeatedly on

low oil level may cause excessive wear which can

be cumulative.

INITIAL START UP

The throttle control on these generators is preset

and locked to operate at 3600 RPM (nominal) with

no load speed set at 690 RPM. Only a trained

service technician should be allowed to adjust this

speed setting.

NOTICE: ENGINE START LOCKOUT

This unit will not start if it is low on oil. The lu-

bricating oil level must be at the

full mark before the

engine will start and run.

BASIC OPERATION

MANUAL STARTING

Refer to the engine manual for additional starting,

operating, and stopping instructions.

1. Check oil level. Refill as needed.

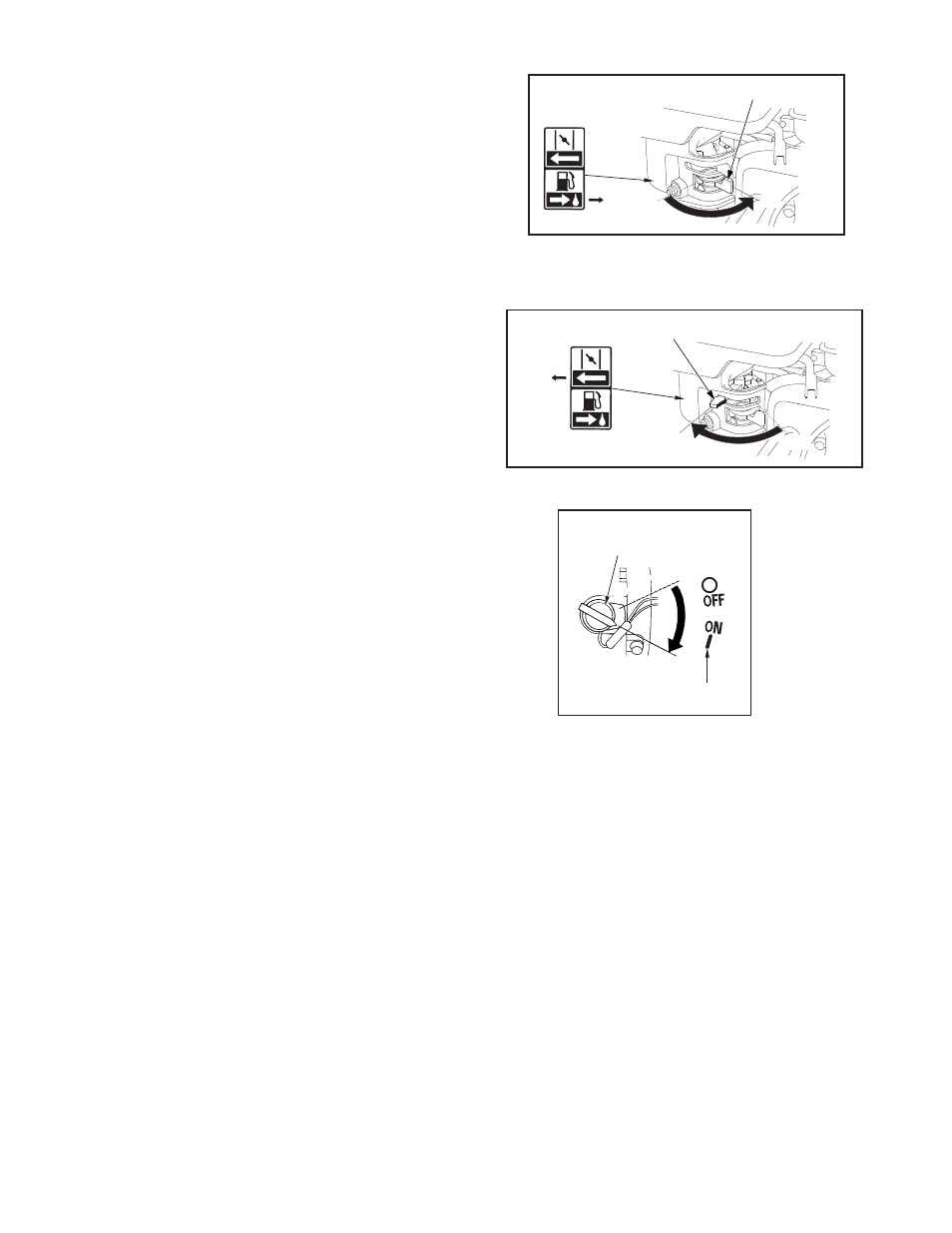

2. Turn on the fuel supply by moving the fuel lever

to the “ON” position.

. Move the choke lever to the “CLOSED” position.

To restart a warm engine, leave the choke lever

in the “OPEN” position

4 Turn the off/on engine switch to the on position.

5. Pull the starter grip lightly until resistance is felt,

then pull briskly.

6. When the engine starts, open the choke

gradually.

7. The engine should promptly come up to

operating speed.

NOTICE:

Do not allow the starter grip to snap back against

the engine. Return it gently to prevent damage to the

starter.

CAUTION: EQUIPMENT DAMAGE

Never permit the choke to remain on after the

engine has run for a short time. It is not necessary to

choke the engine when it is warm. Avoid over-chok-

ing.

OPERATION

SAFE OPERATING PRECAUTIONS

STARTING THE ENGINE

ELECTRIC STARTER TYPES

EXCEPT ELECTRIC

STARTER TYPES

ENGLISH

OFF

O

O

N

N

M

M

A

A

X

X

.

.

1/3 POSITION

THROTTLE LEVER

ENGINE SWITCH

ON

M

M

I

I

N

N

.

.

O

O

P

P

E

E

N

N

CLOSED

CLOSED

O

O

P

P

E

E

N

N

ENGINE SWITCH

ENGINE SWITCH

FUEL VALVE LEVER

O

O

N

N

C

C

L

L

O

O

S

S

E

E

D

D

CHOKE LEVER

ON

ON

ON

ON

ON

M

M

I

I

N

N

.

.

CHOKE ROD (applicable types)

4

Before operating the engine for the first time, please review the

SAFETY INFORMATION section on page and the BEFORE

OPERATION CHECKS on page .

Review the instructions provided with the equipment powered by

this engine for any safety precautions that should be observed

with engine startup, shutdown or operation.

Carbon monoxide gas is toxic. Breathing it can cause

unconsciousness and even kill you.

Avoid any areas or actions that expose you to carbon

monoxide.

Move the fuel valve lever to the ON position.

To start a cold engine, move the choke lever or choke rod

(applicable types) to the CLOSED position.

Move the throttle lever away from the MIN. position, about 1/3

of the way toward the MAX. position.

Some engine applications use a remote-mounted choke control

rather than the engine-mounted choke lever shown here. Refer

to the instructions provided by the equipment manufacturer.

To restart a warm engine, leave the choke lever or choke rod in

the OPEN position.

Some engine applications use a remote-mounted throttle control

rather than the engine-mounted throttle lever shown here. Refer to

the instructions provided by the equipment manufacturer.

Turn the engine switch to the ON position.

3.

4.

1.

2.

2

3

4

ENGLISH

BEFORE OPERATION CHECKS

IS YOUR ENGINE READY TO GO?

For your safety, to ensure compliance with environmental

regulations, and to maximize the service life of your equipment, it is

very important to take a few moments before you operate the

engine to check its condition. Be sure to take care of any problem

you find, or have your servicing dealer correct it, before you operate

the engine.

Before beginning your pre-operation checks, be sure the engine is

level and the engine switch is in the OFF position.

Always check the following items before you start the engine:

Check the General Condition of the Engine

1. Look around and underneath the engine for signs of oil or

gasoline leaks.

2. Remove any excessive dirt or debris, especially around the

muffler and recoil starter.

3. Look for signs of damage.

4. Check that all shields and covers are in place, and all nuts, bolts,

and screws are tightened.

Check the Engine

1. Check the fuel level (see page 8). Starting with a full tank will

help to eliminate or reduce operating interruptions for refueling.

2. Check the engine oil level (see page 9). Running the engine with

a low oil level can cause engine damage.

The Oil Alert system (applicable types) will automatically stop

the engine before the oil level falls below safe limits. However, to

avoid the inconvenience of an unexpected shutdown, always

check the engine oil level before startup.

3. Check the reduction case oil level on applicable types (see page

9). Oil is essential to reduction case operation and long life.

4. Check the air filter element (see page 10). A dirty air filter

element will restrict air flow to the carburetor, reducing engine

performance.

5. Check the equipment powered by this engine.

Review the instructions provided with the equipment powered

by this engine for any precautions and procedures that should

be followed before engine startup.

Improperly maintaining this engine, or failure to

correct a problem before operation, can cause a

malfunction in which you can be seriously hurt or

killed.

Always perform a pre-operation inspection before

each operation, and correct any problem.

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the

SAFETY INFORMATION section on page 2 and the BEFORE

OPERATION CHECKS on page 4.

For your safety, do not operate the engine in an enclosed area such

as a garage. Your engine’s exhaust contains poisonous carbon

monoxide gas that can collect rapidly in an enclosed area and cause

illness or death.

Review the instructions provided with the equipment powered by

this engine for any safety precautions that should be observed with

engine startup, shutdown, or operation.

Do not operate the engine on slopes greater than 20° (36%).

STARTING THE ENGINE

1. Move the fuel valve lever to the ON position.

2. To start a cold engine, move the choke lever to the CLOSED

position.

To restart a warm engine, leave the choke lever in the OPEN

position.

Some engine applications use a remote-mounted choke control

rather than the engine-mounted choke lever shown here. Refer

to the instructions provided by the equipment manufacturer.

Exhaust contains poisonous carbon monoxide gas

that can build up to dangerous levels in closed areas.

Breathing carbon monoxide can cause

unconsciousness or death.

Never run the engine in a closed, or even partly closed

area where people may be present.

FUEL VALVE LEVER

ON

OFF

ON

CHOKE LEVER

CLOSED

CLOSED

OPEN

4

ENGLISH

BEFORE OPERATION CHECKS

IS YOUR ENGINE READY TO GO?

For your safety, to ensure compliance with environmental

regulations, and to maximize the service life of your equipment, it is

very important to take a few moments before you operate the

engine to check its condition. Be sure to take care of any problem

you find, or have your servicing dealer correct it, before you operate

the engine.

Before beginning your pre-operation checks, be sure the engine is

level and the engine switch is in the OFF position.

Always check the following items before you start the engine:

Check the General Condition of the Engine

1. Look around and underneath the engine for signs of oil or

gasoline leaks.

2. Remove any excessive dirt or debris, especially around the

muffler and recoil starter.

3. Look for signs of damage.

4. Check that all shields and covers are in place, and all nuts, bolts,

and screws are tightened.

Check the Engine

1. Check the fuel level (see page 8). Starting with a full tank will

help to eliminate or reduce operating interruptions for refueling.

2. Check the engine oil level (see page 9). Running the engine with

a low oil level can cause engine damage.

The Oil Alert system (applicable types) will automatically stop

the engine before the oil level falls below safe limits. However, to

avoid the inconvenience of an unexpected shutdown, always

check the engine oil level before startup.

3. Check the reduction case oil level on applicable types (see page

9). Oil is essential to reduction case operation and long life.

4. Check the air filter element (see page 10). A dirty air filter

element will restrict air flow to the carburetor, reducing engine

performance.

5. Check the equipment powered by this engine.

Review the instructions provided with the equipment powered

by this engine for any precautions and procedures that should

be followed before engine startup.

Improperly maintaining this engine, or failure to

correct a problem before operation, can cause a

malfunction in which you can be seriously hurt or

killed.

Always perform a pre-operation inspection before

each operation, and correct any problem.

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the

SAFETY INFORMATION section on page 2 and the BEFORE

OPERATION CHECKS on page 4.

For your safety, do not operate the engine in an enclosed area such

as a garage. Your engine’s exhaust contains poisonous carbon

monoxide gas that can collect rapidly in an enclosed area and cause

illness or death.

Review the instructions provided with the equipment powered by

this engine for any safety precautions that should be observed with

engine startup, shutdown, or operation.

Do not operate the engine on slopes greater than 20° (36%).

STARTING THE ENGINE

1. Move the fuel valve lever to the ON position.

2. To start a cold engine, move the choke lever to the CLOSED

position.

To restart a warm engine, leave the choke lever in the OPEN

position.

Some engine applications use a remote-mounted choke control

rather than the engine-mounted choke lever shown here. Refer

to the instructions provided by the equipment manufacturer.

Exhaust contains poisonous carbon monoxide gas

that can build up to dangerous levels in closed areas.

Breathing carbon monoxide can cause

unconsciousness or death.

Never run the engine in a closed, or even partly closed

area where people may be present.

FUEL VALVE LEVER

ON

OFF

ON

CHOKE LEVER

CLOSED

CLOSED

OPEN