VACUUBRAND RC 6 User Manual

Page 42

page 42 of 59

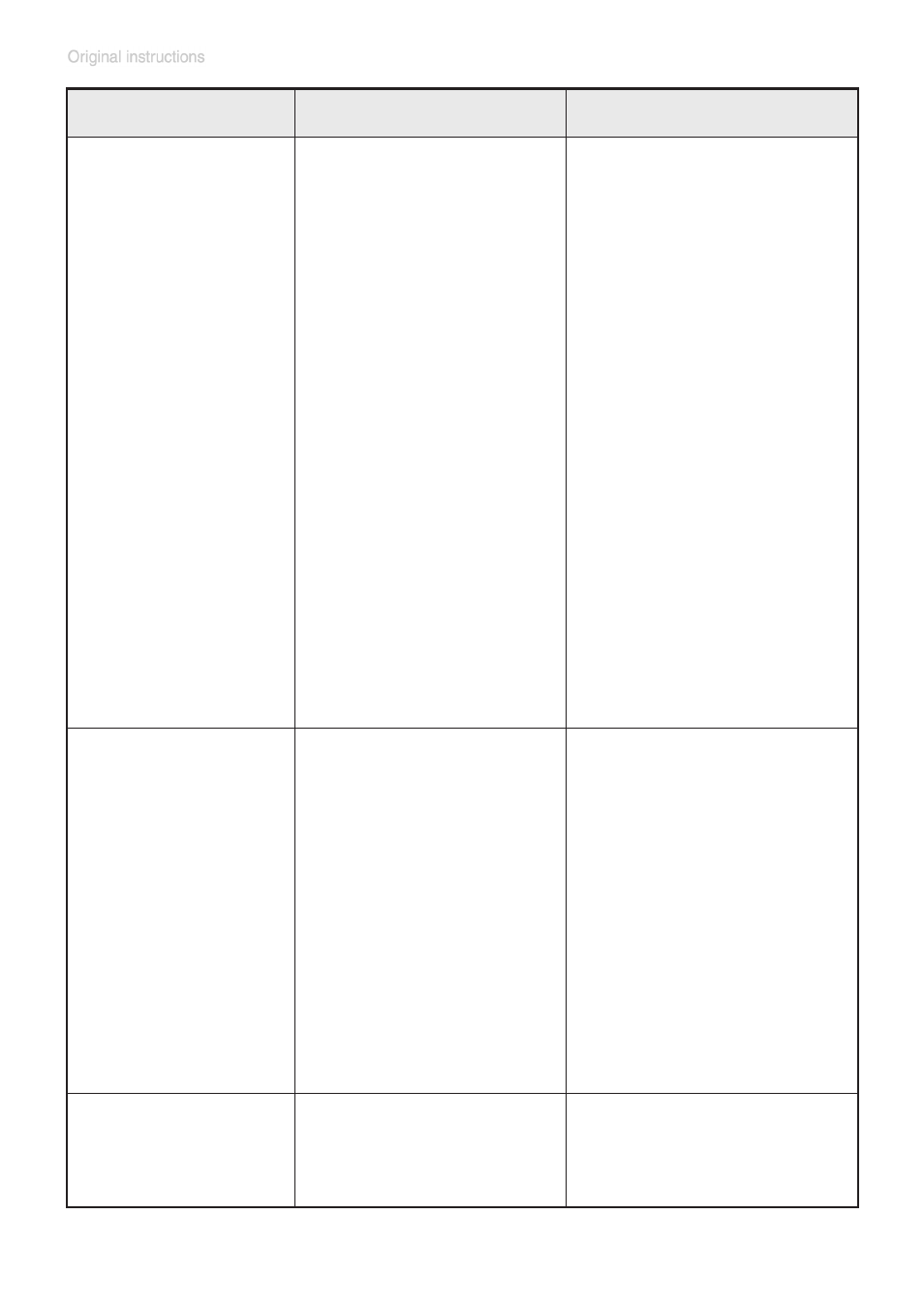

Fault

Possible cause

Remedy

❑ Pump does not

achieve its ultimate

vacuum or usual

pumping speed.

➨ Leak in the pipeline or

vacuum system?

✔ Check pump directly -

connect vacuum gauge

directly at pump inlet -

then check connection,

pipeline and vacuum

system if necessary.

➨ Long, narrow vacuum

line?

✔ Use lines with larger di-

ameter, length as short as

possible.

➨ Not enough oil?

✔ Top up oil to correct level.

➨ Wrong type of oil?

✔ Change oil and flush with

oil (see ”Oil change”).

➨ Oil contaminated (also

with solvents)?

✔ Change oil and flush with

oil (see ”Oil change”).

➨ Outgassing substances

or vapor generated in

the process?

✔ Check process parame-

ters.

➨ Pump has not yet

reached its operating

temperature?

✔ Allow the pump to reach

its operating temperature.

➨ None of the above

mentioned causes?

✔ Contact local distributor.

❑ Pump too noisy or

strange noise.

➨ Too much oil?

✔ Lower oil level to mark

”max.”.

➨ Motor thermally over-

loaded?

✔ Allow motor to cool down

(< 50°C (122°F)), identify

and eliminate cause of

failure. Provide sufficient

ventilation.

➨ Diaphragm damaged? ✔ Replace diaphragm.

➨ Pump seized?

✔ See below.

➨ Overpressure in outlet

line?

✔ Remove blockage in line,

open valve.

➨ None of the above

mentioned causes?

✔ Contact local distributor.

❑ Oil in the inlet line. ➨ Back diffusion (small

amount of oil, oil film)?

✔ Install a sorption trap or a

separator, if necessary.

➨ Back streaming (large

amount of oil)?

✔ Contact local distributor.