Notice – VACUUBRAND RC 6 User Manual

Page 31

page 31 of 59

For

condensable vapors (water vapor, sol-

vents, etc.):

- Let the pump run

with gas ballast to re-

duce condensation of pumped substances

(water vapor, solvents, ....) in the pump or

to decontaminate the pump oil from volatile

substances.

- With gas ballast valve open, the ultimate vacuum will

be reduced.

- Use inert gas for gas ballast to avoid the formation of

explosive mixtures.

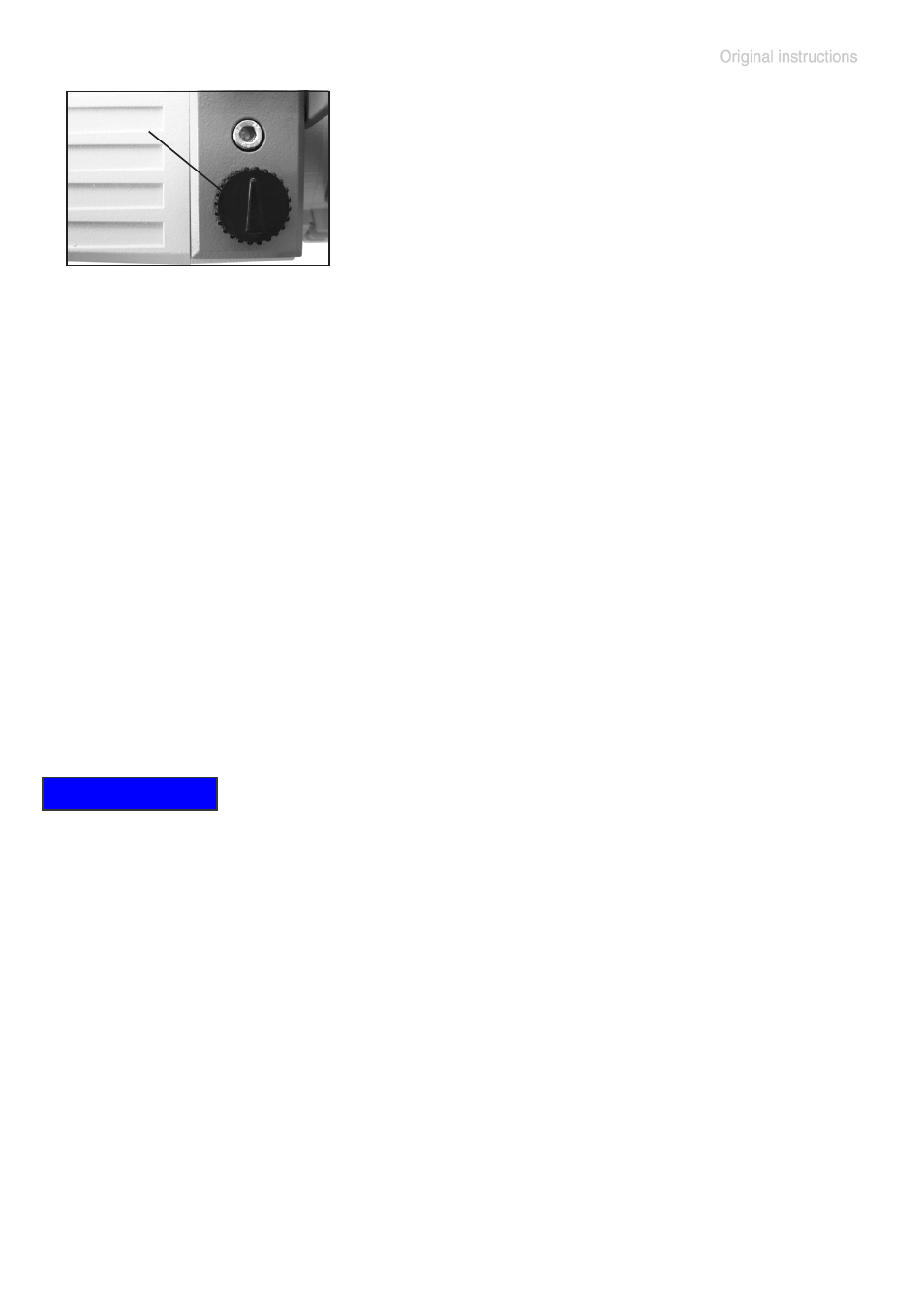

- To open and to close the gas ballast valve turn the

gas ballast valve cap. The manual gas ballast valve

is open if the arrow on the gas ballast cap is pointing

towards the inlet of the pump respectively towards the

labelling ”Gasballast”.

- Close the manual gas ballast valve by turning the cap

180°.

Operate the pump without gas ballast only in case of

a clean system or when there are no condensable va-

pors.

Do not pump vapors until the pump has reached its oper-

ating temperature. Install an in-line valve in the inlet line

and open it only approx. 30 minutes after the pump has

been started.

Check the maximum vapor inlet pressure. The pump can

operate continuously at any pressure lower than the maxi-

mum specified inlet pressure for vapor. Avoid sudden va-

por surges when evacuating commences (large inner sur-

faces, large-volume vacuum vessel).

Use a flow-control valve in the inlet line and open the valve

gradually.

gas ballast

(open)

NOTICE