TriangleTube TTP Series User Manual

Page 8

general Installation

6

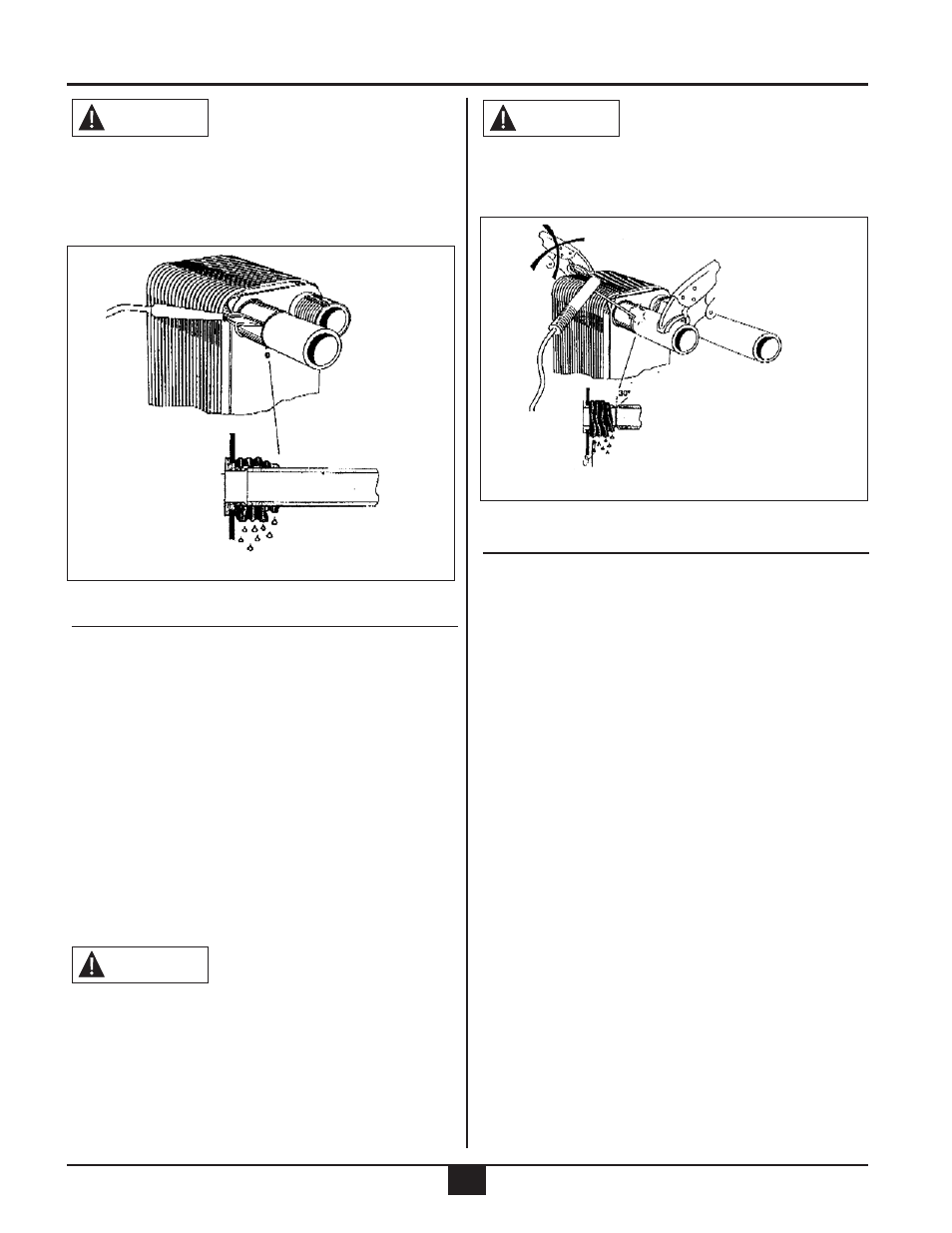

do not braze the heat exchanger in a horizontal or

flat position. Solder material may fall into the heat

exchanger or piping connection, creating a blockage

within the distribution channels . direct the flame

away from the heat exchanger

WEldIng ProCEdurES

1. Prepare the edge of the connecting pipe for

welding with a 30º angle chamfer.

2. Place the connecting pipe into the heat

exchanger connection.

3. Use TIG or MIG/MAG welding method filling the

groove form by the two edges.

4. For refrigerant applications, purge using dry

nitrogen gas on the refrigerant side to prevent

internal oxidation.

5. Heat the welding area to approximately 1200ºF

(650ºC). Use a wet cloth to protect the heat-

exchanger while welding.

When using electrical welding circuits, connect the

ground terminal to the joining tube, do not connect

to the back of the heat exchanger. damage to the

internal channels and/or brazing material of the heat

exchanger could occur.

WARNING

WARNING

do not heat the welding area higher than 1200ºf.

damage to the heat exchanger brazing material

could occur.

THrEadEd ConnECTIonS

General Guidelines

•

Use Teflon or Mylar tape or other sealant on the

male threaded part of the heat exchanger connec-

tion to prevent leakage.

•

Use a back-up-wrench method when installing

threaded connections. DO NOT over torque the con-

nection. Over tightening connection will damage the

heat exchanger.

WARNING

fig. 5: Welded Connection

fig. 4: Solder Connection