TriangleTube TTP Series User Manual

Page 15

applications

13

STEaM To WaTEr aPPlICaTIonS

•

Ensure the braze plate heat exchanger is mounted

vertically to allow gravity drainage of the conden-

sate.

• The installer should use “Good Steam Practices”

which include a steam trap below the unit and vacu-

um breakers.

•

The steam circuit must enter the heat exchanger’s

top connection, with the condensate leaving the heat

exchanger through the bottom connection.

•

Provide steam traps at critical points e.g. in front of

the control valve, to prevent “pooling” of condensate.

Water Hammer and other deformations Caused By

Wet Steam: a high moisture content in the steam

could condense within the heat exchanger forming

pools of water at critical points, exposing the sys-

tem and the heat exchanger to water hammer. one

critical point is the area ahead of the control valve

when the valve is located ahead of the inlet to the

heat exchanger. When the control valve is in the

close position the stationary steam in front of the

valve is subject to condense. Heat losses due to

radiation and/or faulty insulation can increase the

rate of condensation. also, when the control valve

is in the closed position, condensation on the plates

of the heat exchanger occurs, producing a vacuum

or negative pressure inside the heat exchanger.

When the control valve opens to admit steam to the

heat exchanger, the differential in pressure causes a

sudden acceleration in the steam flow, pulling the

accumulated water into the heat exchanger at a high

velocity. The amount of energy produced by this

water at a high velocity can be very great, resulting

in heavy wear and tear and other mechanical dam-

age in the heat exchanger, which results in potential

leaks.

avoidance Practices: on low pressure steam sys-

tems or on applications with no-continuous process-

es, place traps prior to the control valve and other

critical points in the steam distribution system.

for sizing applications using steam it is recom-

mended to contact Triangle Tube’s Engineering

department.

NOTICE

NOTICE

rEfrIgEranT (CondEnSEr / EvaPoraTor)

aPPlICaTIonS

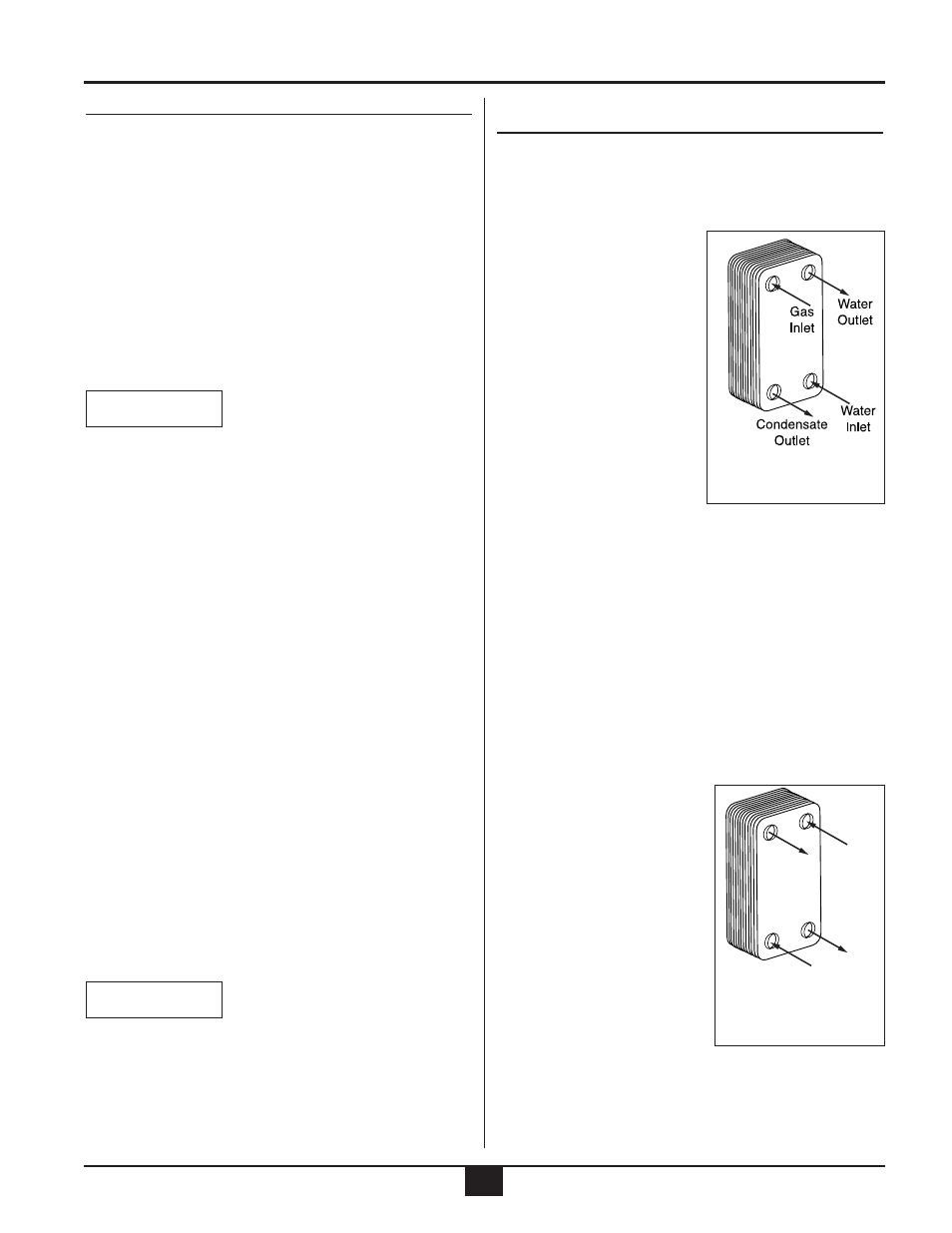

Condenser applications

•

The heat exchanger must be mounted in a vertical

position to allow gravity drainage of the condensate.

•

The refrigerant gas

must enter the heat

exchanger on the left

side (as indicated by the

color label) using the

upper connection.

•

The cooling water must

enter the lower right con-

nection of the heat

exchanger and exit from

the upper right connec-

tion. This will maintain

the counter flow concept.

Evaporator applications

•

The heat exchanger must be mounted in a vertical

position.

•

The refrigerant gas/liquid mixture must enter the

heat exchanger on the left side (as indicated by the

colored label) using the lower connection.

•

The water must enter the upper right connection of

the heat exchanger and exit from the lower right con-

nection. This will maintain the counter flow concept.

•

The thermal expansion valve should be placed close

to the inlet connection of the heat ex- changer. The

thermal expansion val- ve

sensing bulb should be

placed on the refrigerant

outlet pipe approximately

12 to 24 inches from the

heat exchanger.

•

A pressure differential

switch or flow switch

must be installed to pre-

vent possible freeze-up

due to loss of water flow.

Water

Inlet

Water

Outlet

Gas

Outlet

Gas/Liquid

Inlet

fig.13: Condenser

applications

fig.14: Evaporator

applications