Additional information for low threshold shower, Installing the back wall – Trending Accessibility Four Piece Barrier Free User Manual

Page 4

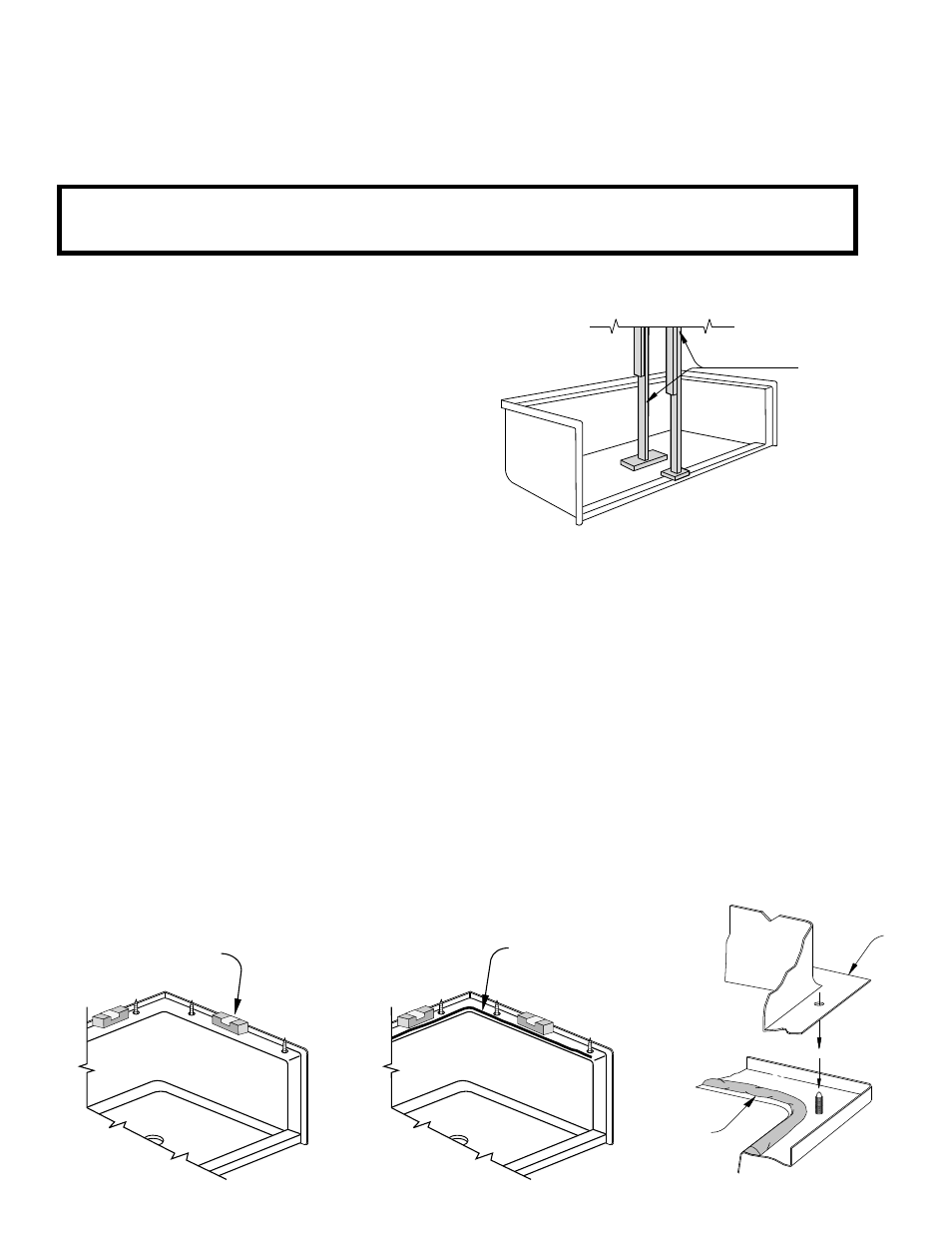

Wood Blocks

Taped in Place

1/4” Bead of

Silicone Caulk

Check level in two directions: Front to back and side to side. Use a carpenters level placed on top of the

threshold and along the top surface of each side wall.

17.

Shower bases installed into Thin-Set may be adjusted for level by gently shifting the base into the mortar unit level

is acheived. Units with factory Easy Base, may have small adjustment by using thin wood shims.

It is essential the shower base be VERY level and pumb in order to acheive a successful shower installation.

The low threshold shower is constructed without wood reinforcement built into the bottom. It is critical that

factory shape of the shower floor and threshold be maintained.

Cut a 2 x 4 member of 10” to place directly over

the drain area. Cut a similar member and place

on top of the threshold at the center. Install cloth

or cardboard under these boards to protect the

gelcoat finish.

Install 2 x 4’s on top of each of the blocks that

extend to the ceiling.

This should be a tight fit.

The purpose of this bracing is to hold the drain

area and threshold in the proper factory position.

This bracing must be done immediately after Step

15 before the support materials have had a chance

to set up. (See Figure 4).

ADDITIONAL INFORMATION FOR LOW THRESHOLD SHOWER

Wood 2 x 4’s

to ceiling

A torpedo level should be placed from floor to assure the unit has proper slope for drainage. If unit

doesn’t drain properly, the unit must be pulled back to determine where the problem lies.

If any high spots are found, remove excess mortar to correct the problem. Low spots must also be corrected

to avoid pooling of water.

Perform a test walk in the unit to determine the floor is stable and without flex. The mortar and adhesive should

be given time to firm up before installing the wall sections. Working in the unit too soon could cause the

reinforcing materials to shift resulting in depressions in the floor. Under normal conditions, waiting 90 minutes

before installing the wall sections should give enough time for the materials to firm up. Leave the wood bracing

in place 72 hours to achieve full cure.

Back

Wall

Caulking

on

Base

The silicone around the plastic fasteners should be cured before proceeding to the wall installation.

INSTALLING THE BACK WALL

Use 6 wooden 2 x 2 blocks spaced evenly along the top connection surface of the shower base. These blocks

will hold the wall sections above the mounting surface until you are ready for final installation. Use masking tape

to temporarily secure the blocks. See Figure 5.

Apply a continuous bead of silicone caulk to the top connection surface. Apply the caulk between the inside

edge and plastic fasteners. (See Figure 6). The holes in the back wall mounting surface will index with the

plastic fasteners to line up the part with the base. The caulking will secure the parts together when it cures.

See Figure 7.

4

Fasten the shower base to the framing through the flanges using 6D galvanized screws on 8 inch centers along

both sides, across the back and at the front of each side vertically.

20.

18.

19.

21.

22.

23.

24.

25.

Figure 5

Figure 4

Figure 6

Figure 7